SNOS694I March 1995 – September 2015 LMC6001

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Conditions

- 6.4 Thermal Information

- 6.5 DC Electrical Characteristics for LMC6001AI

- 6.6 DC Electrical Characteristics for LMC6001BI

- 6.7 DC Electrical Characteristics for LMC6001CI

- 6.8 AC Electrical Characteristics for LMC6001AIC

- 6.9 AC Electrical Characteristics for LM6001BI

- 6.10 AC Electrical Characteristics for LMC6001CI

- 6.11 Dissipation Ratings

- 6.12 Typical Characteristics

- 7 Detailed Description

- 8 Applications and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- P|8

Thermal pad, mechanical data (Package|Pins)

Orderable Information

10 Layout

10.1 Layout Guidelines

10.1.1 Printed-Circuit-Board Layout For High-Impedance Work

It is generally recognized that any circuit which must operate with less than 1000 pA of leakage current requires special layout of the PCB. When one wishes to take advantage of the ultra-low bias current of the LMC6001, typically less than 10 fA, it is essential to have an excellent layout. Fortunately, the techniques of obtaining low leakages are quite simple. First, the user must not ignore the surface leakage of the PCB, even though it may sometimes appear acceptably low, because under conditions of high humidity or dust or contamination, the surface leakage will be appreciable.

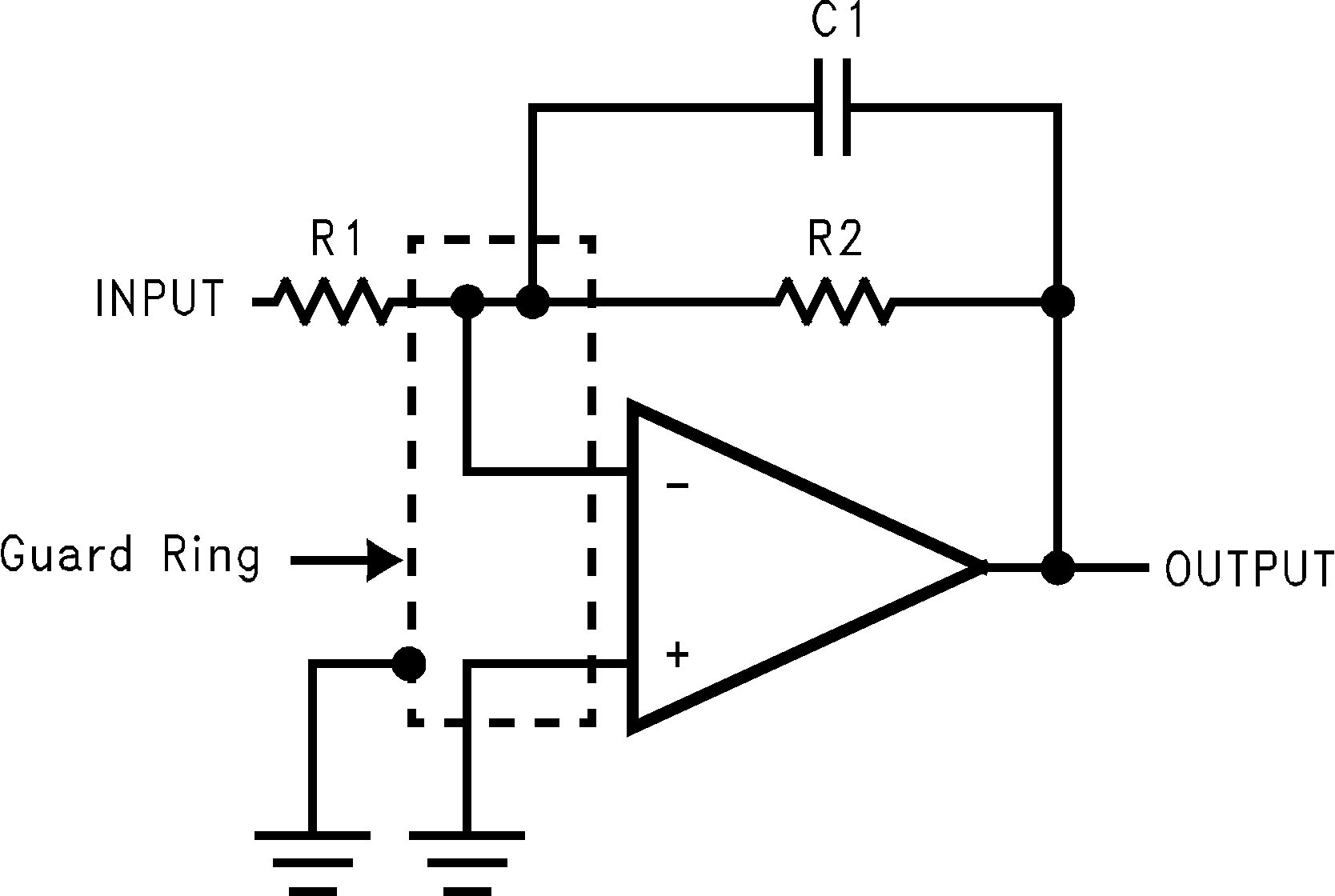

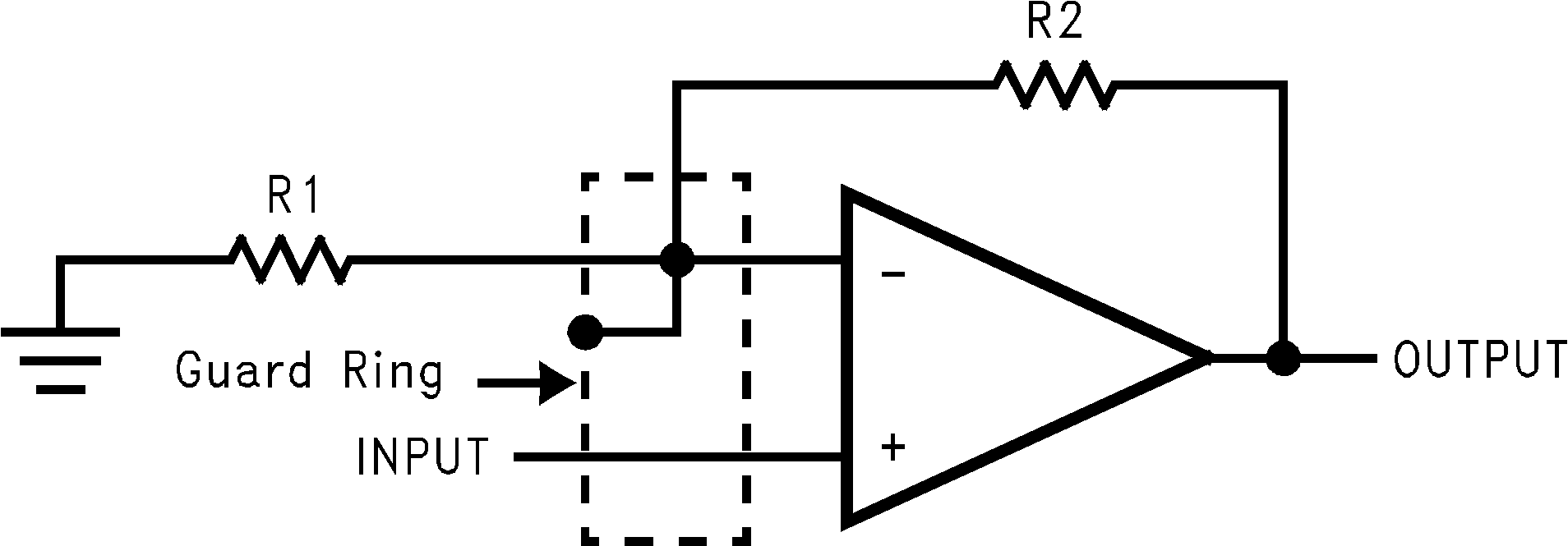

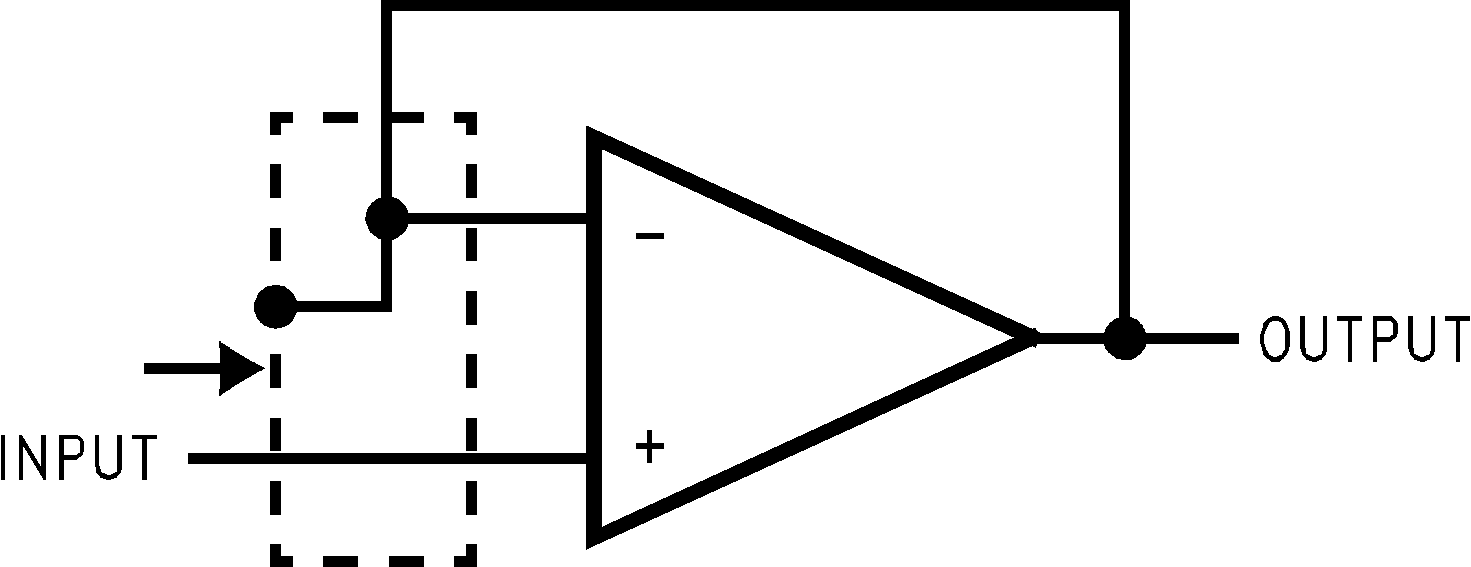

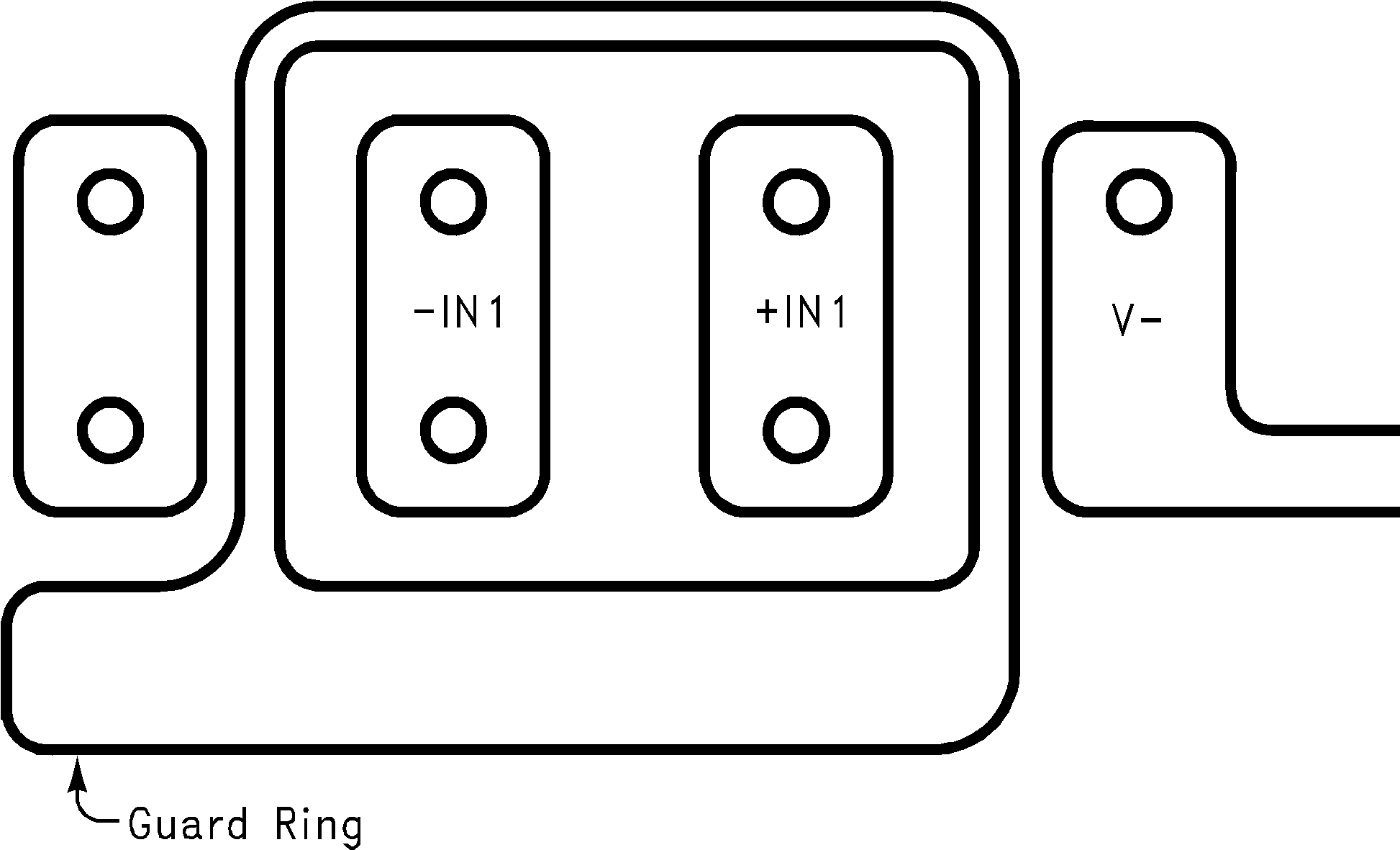

To minimize the effect of any surface leakage, lay out a ring of foil completely surrounding the inputs of the LMC6001 and the terminals of capacitors, diodes, conductors, resistors, relay terminals, and so forth, connected to the inputs of the op amp, as in Figure 30. To have a significant effect, guard rings must be placed on both the top and bottom of the PCB. This PC foil must then be connected to a voltage which is at the same voltage as the amplifier inputs, because no leakage current can flow between two points at the same potential. For example, a PCB trace-to-pad resistance of 10 TΩ, which is normally considered a very large resistance, could leak 5 pA if the trace were a 5-V bus adjacent to the pad of the input.

This would cause a 500 times degradation from the LMC6001's actual performance. If a guard ring is used and held within 1 mV of the inputs, then the same resistance of 10 TΩ will only cause 10 fA of leakage current. Even this small amount of leakage will degrade the extremely low input current performance of the LMC6001. See Figure 28 for typical connections of guard rings for standard op amp configurations.

Figure 26. Inverting Amplifier

Figure 26. Inverting Amplifier

Figure 27. Noninverting Amplifier

Figure 27. Noninverting Amplifier

Figure 28. Typical Connections Of Guard Rings

Figure 28. Typical Connections Of Guard Rings

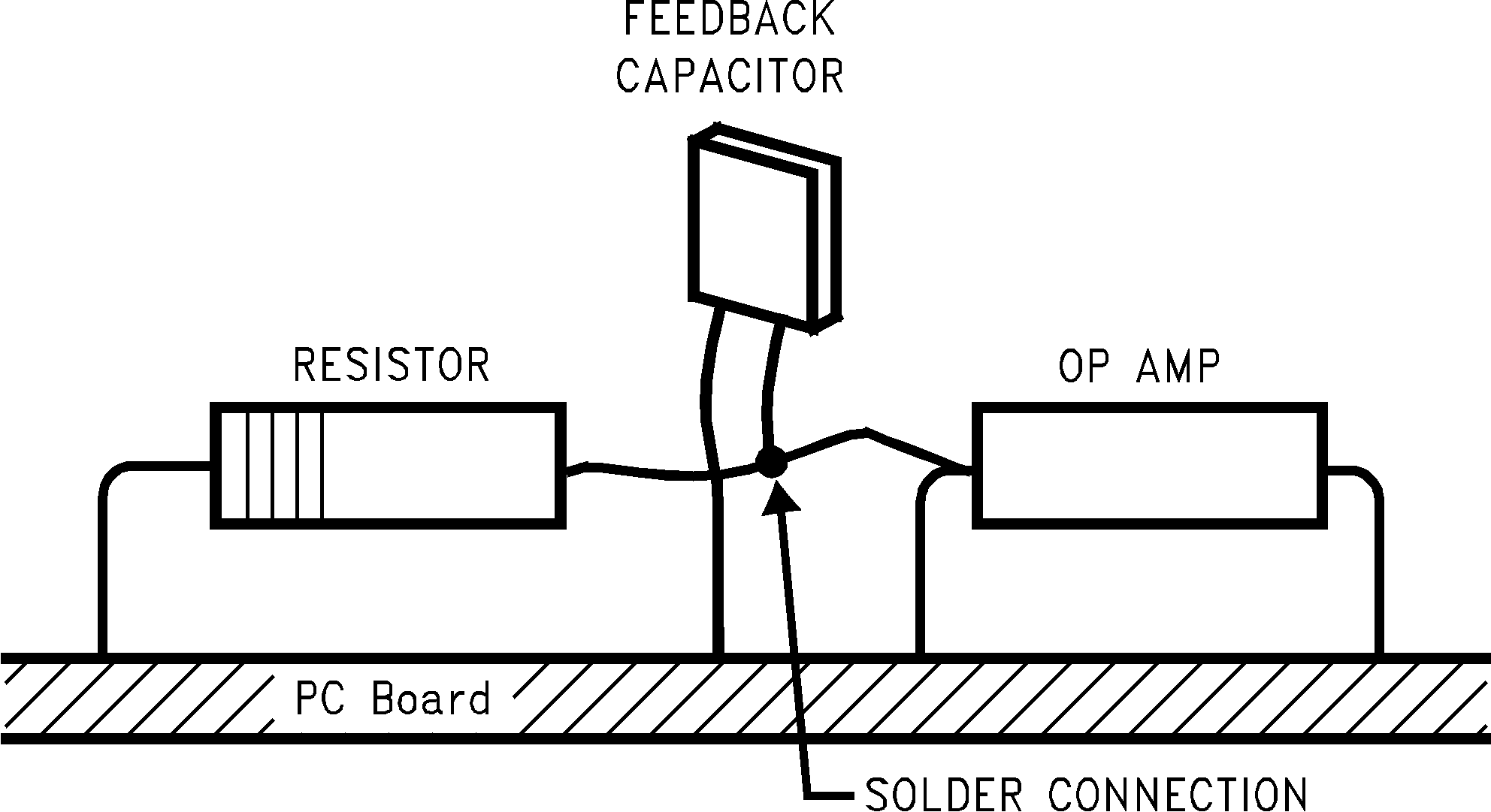

The designer should be aware that when it is inappropriate to lay out a PCB for the sake of just a few circuits, there is another technique which is even better than a guard ring on a PCB: Do not insert the input pin of the amplifier into the board at all, but bend it up in the air and use only air as an insulator. Air is an excellent insulator. In this case you may have to forego some of the advantages of PCB construction, but the advantages are sometimes well worth the effort of using point-to-point up-in-the-air wiring. See Figure 29.

Another potential source of leakage that might be overlooked is the device package. When the LMC6001 is manufactured, the device is always handled with conductive finger cots. This is to assure that salts and skin oils do not cause leakage paths on the surface of the package. We recommend that these same precautions be adhered to, during all phases of inspection, test and assembly.

10.2 Layout Example

Figure 30. Examples Of Guard

Figure 30. Examples Of GuardRing In PCB Layout