SLVSDG2G July 2016 – December 2019 TPS2660

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Parameter Measurement Information

-

9 Detailed Description

- 9.1 Overview

- 9.2 Functional Block Diagram

- 9.3

Feature Description

- 9.3.1 Undervoltage Lockout (UVLO)

- 9.3.2 Overvoltage Protection (OVP)

- 9.3.3 Reverse Input Supply Protection

- 9.3.4 Hot Plug-In and In-Rush Current Control

- 9.3.5 Overload and Short Circuit Protection

- 9.4 Device Functional Modes

-

10Application and Implementation

- 10.1 Application Information

- 10.2

Typical Application

- 10.2.1 Design Requirements

- 10.2.2 Detailed Design Procedure

- 10.2.3 Application Curves

- 10.3 System Examples

- 10.4 Do's and Don'ts

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

- 14Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- RHF|24

- PWP|16

Thermal pad, mechanical data (Package|Pins)

- PWP|16

Orderable Information

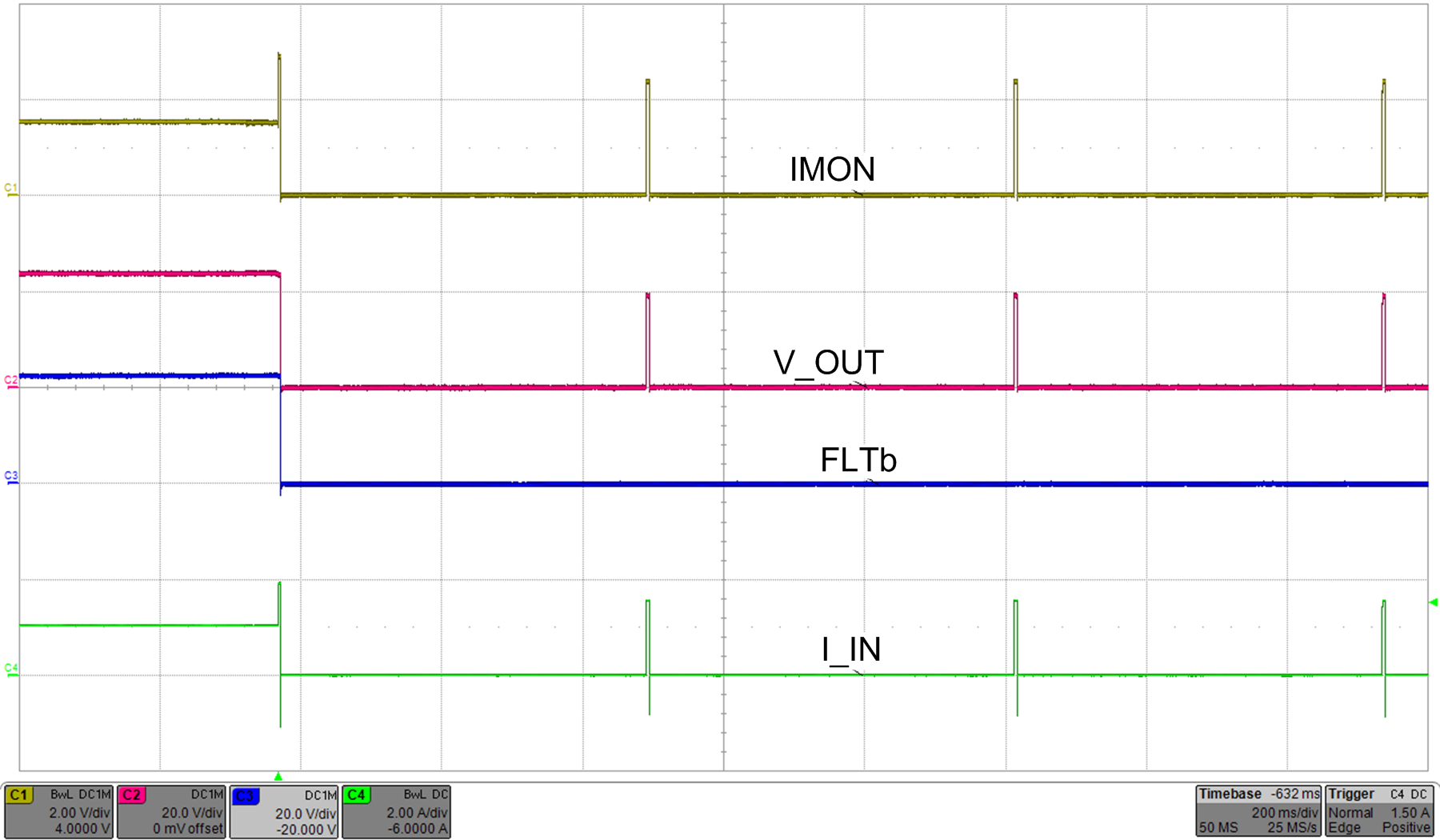

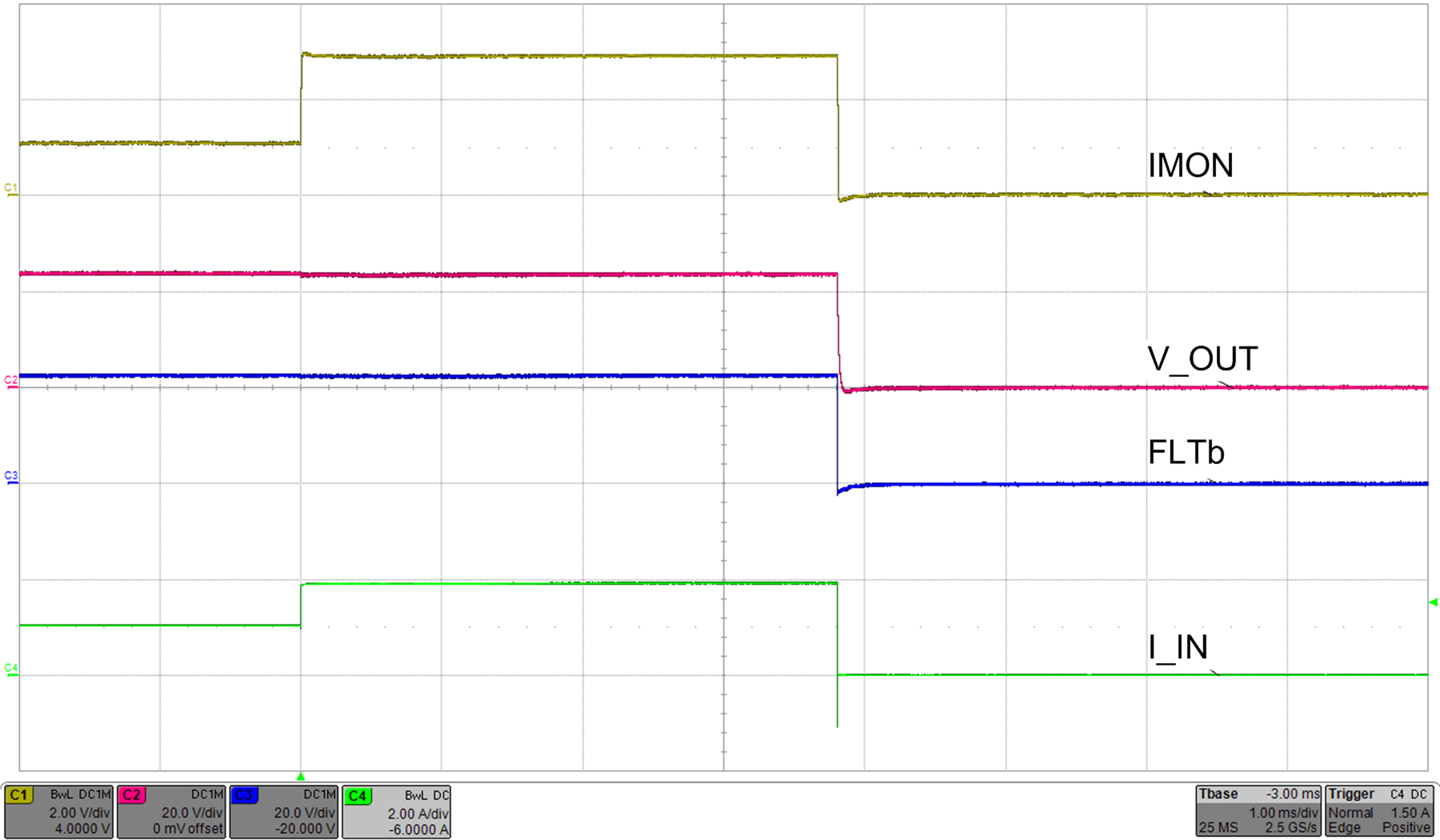

9.3.5.1.2 Electronic Circuit Breaker with Overload Timeout, MODE = OPEN

In this mode, during overload events, the device allows the overload current to flow through the device until I(LOAD) < I(FASTRIP). The circuit breaker threshold I(CB) can be programmed using the R(ILIM) resistor as shown in Equation 4.

where

- I(CB) is circuit breaker current threshold in Ampere

- R(ILIM) is the current limit resistor in kΩ

An internal timer starts when I(CB) < ILOAD < IFASTRIP, and when the timer exceeds tCB(dly), the device turns OFF the internal FET and FLT is asserted. Once the internal FET is turned off, the device configured in latch-off mode stays latched off, until it is reset by either of the following conditions:

- Cycling V(IN) falling below V(PORF)

- Toggling SHDN

whereas the device configured in auto-retry mode, commences an auto-retry cycle after 540 ms. The FLT signal remains asserted until the fault condition is removed and the device resumes normal operation. Figure 41 and Figure 42 illustrate behavior of the system during electronic circuit breaker with auto-retry functionality.

| MODE left floating | Load Transition from 22 Ω to 12 Ω | |

| RILIM = 8 kΩ | ||

| Load Transition from 22 Ω to 12 Ω , RILIM = 8 kΩ | ||