SLVSEC6D June 2019 – March 2020 TPS62840

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Description

- 8.3.1 Smart Enable and Shutdown

- 8.3.2 Soft Start

- 8.3.3 Mode Selection: Power-Save Mode (PFM/PWM) or Forced PWM Operation (FPWM)

- 8.3.4 Output Voltage Selection (VSET)

- 8.3.5 Undervoltage Lockout UVLO

- 8.3.6 Switch Current Limit / Short Circuit Protection

- 8.3.7 Output Voltage Discharge

- 8.3.8 Thermal Shutdown

- 8.3.9 STOP Mode

- 8.4 Device Functional Modes

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

- DLC|8

Orderable Information

8.4.1 Power-Save Mode Operation

The DCS-Control topology supports Power-Save Mode operation. At light loads, the device operates in PFM (Pulse Frequency Modulation) mode that generates a single switching pulse to ramp up the inductor current and recharge the output capacitor, followed by a sleep period where most of the internal circuits are shutdown to achieve lowest operating quiescent current. During this time, the load current is supported by the output capacitor. The duration of the sleep period depends on the load current and the inductor peak current. During the sleep periods, the current consumption is reduced to typically 60 nA. This low quiescent current consumption is achieved by an ultra-low power reference, an integrated high-impedance feedback divider network, and an optimized Power-Save Mode operation. To achieve a stable switching frequency in steady state operation, the on-time is calculated as in Equation 2.

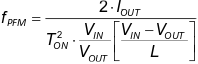

In PFM Mode, the switching frequency varies linearly with the load current and is calculated in Equation 3. At medium and high load conditions, the device enters automatically PWM (Pulse Width Modulation) mode and operates in continuous conduction mode with a nominal switching frequency (fsw). The switching frequency in PWM mode is controlled and depends on VIN and VOUT. The boundary between PWM and PFM mode is when the inductor current becomes discontinuous.

If the load current decreases, the converter seamlessly enters PFM mode to maintain high efficiency down to ultra-light loads. Since DCS-Control supports both operation modes within one single building block, the transition from PWM to PFM modes is seamless with minimum output voltage ripple.