SLPS667A February 2017 – July 2017 CSD17318Q2

PRODUCTION DATA.

- 1Features

- 2Applications

- 3Description

- 4Revision History

- 5Specifications

- 6Device and Documentation Support

- 7Mechanical Data

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DQK|6

Thermal pad, mechanical data (Package|Pins)

Orderable Information

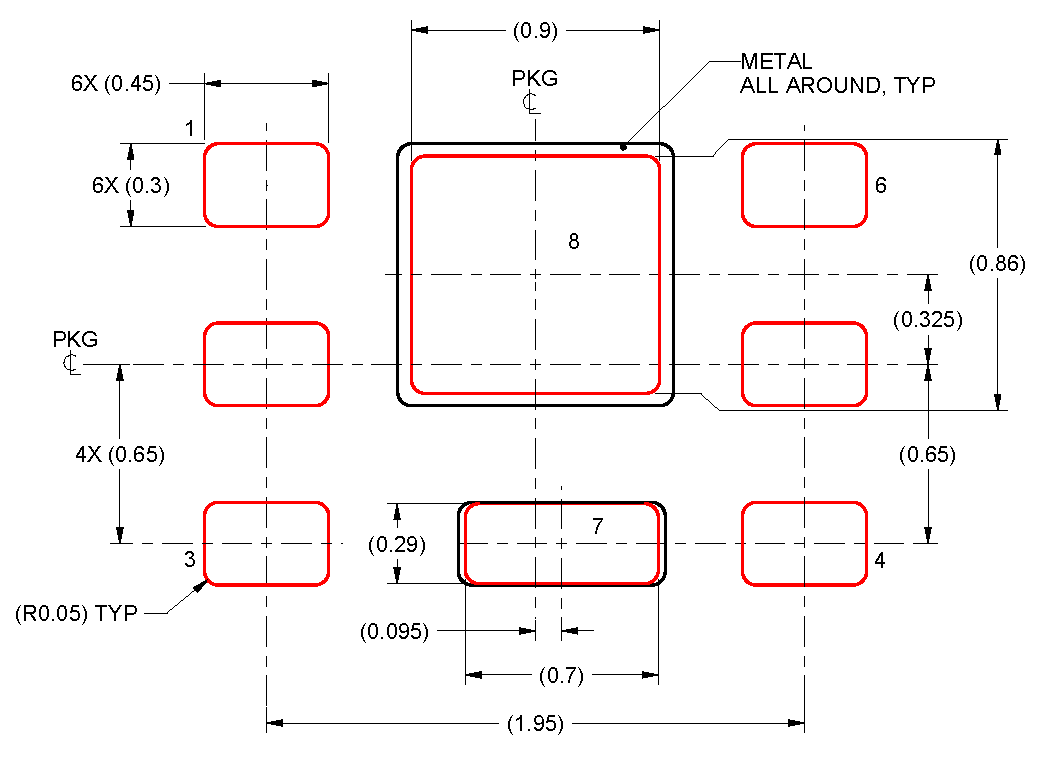

7 Mechanical Data

7.1 Q2 Package Dimensions

- All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing per ASME Y14.5M.

- This drawing is subject to change without notice.

- The package thermal pads must be soldered to the printed circuit board for thermal and mechanical performance.

7.1.1 Recommended PCB Pattern

- This package is designed to be soldered to a thermal pad on the board. For more information, see QFN/SON PCB Attachment (SLUA271).

7.1.2 Recommended Stencil Pattern

- Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate design recommendations.

7.2 Q2 Tape and Reel Information

NOTES:

1. Measured from centerline of sprocket hole to centerline of pocket.2. Cumulative tolerance of 10 sprocket holes is ±0.20.

3. Other material available.

4. Typical SR of form tape Max 109 OHM/SQ.

5. All dimensions are in mm, unless otherwise specified.