SLUSBH2G March 2013 – March 2019

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Maximum Power Point Tracking

- 7.3.2 Battery Undervoltage Protection

- 7.3.3 Battery Overvoltage Protection

- 7.3.4 Battery Voltage within Operating Range (VBAT_OK Output)

- 7.3.5 Storage Element / Battery Management

- 7.3.6 Programming OUT Regulation Voltage

- 7.3.7 Step Down (Buck) Converter

- 7.3.8 Nano-Power Management and Efficiency

- 7.4 Device Functional Modes

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- RGR|20

Thermal pad, mechanical data (Package|Pins)

- RGR|20

Orderable Information

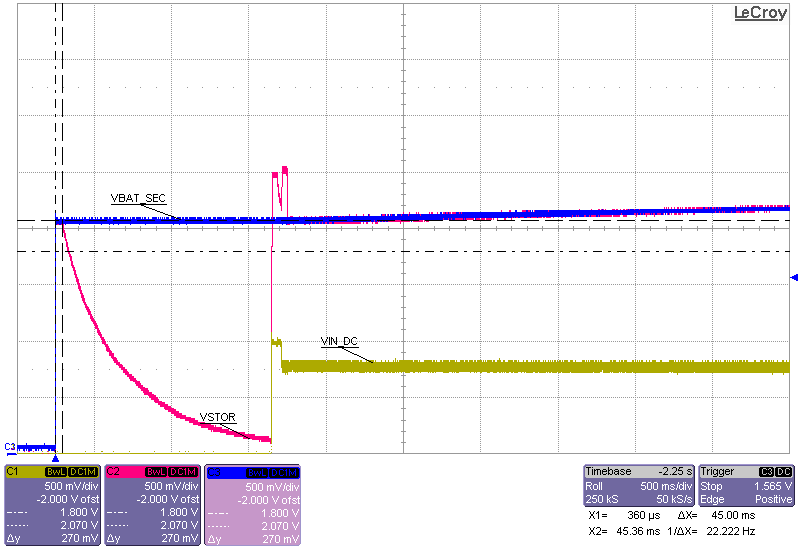

8.2.1.3 Application Curves

| Sourcemeter with VSOURCE = 1.0 V and compliance of 8.5 mA subsequently applied to VIN_DC |

| VBAT = 0.1 F capacitor charged to 2.0 V |

| Resistance on VSTOR = 100 kΩ |

| VIN_DC = sourcemeter with VSOURCE = 2.0 V and compliance

of 43 mA |

| VBAT = sourcemeter with VSOURCE = 3.0 V and compliance

of 1 A |

| VIN_DC = 1.5 V with 75 Ω series resistance |

| No storage element on VBAT or VBAT_PRI |

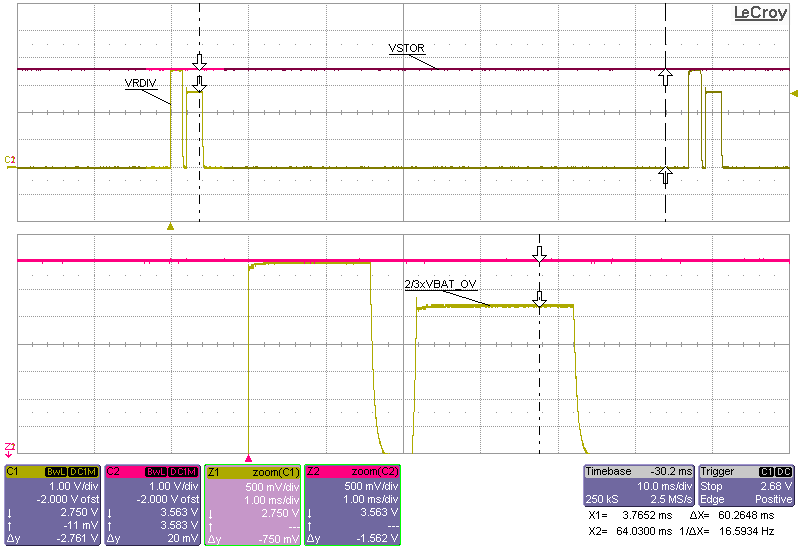

| VSTOR artifically ramped from 0 V to 4.2 V to 0 V using a power amp driven by a function generator |

| VIN_DC = 1.5 V with 75 Ω series resistance |

| VBAT = 4.2 V charged 0.5 F capacitor |

| R(VSTOR) = open to 84 Ω to open |

| VIN_DC = source meter with 1.2 V compliance and ISC = 1.0 mA |

| 120 mF super capacitor on VOUT with VOUT regulation voltage changed to 4.2 V. |

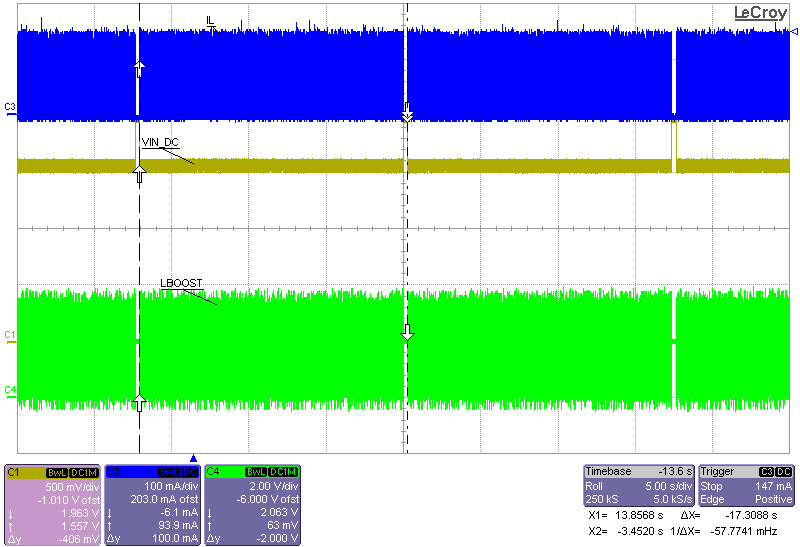

| VIN_DC = sourcemeter with VSOURCE = 2.0 V and compliance of 43 mA |

| VBAT = sourcemeter with VSOURCE = 3.0 V and compliance of |

| 1 A |

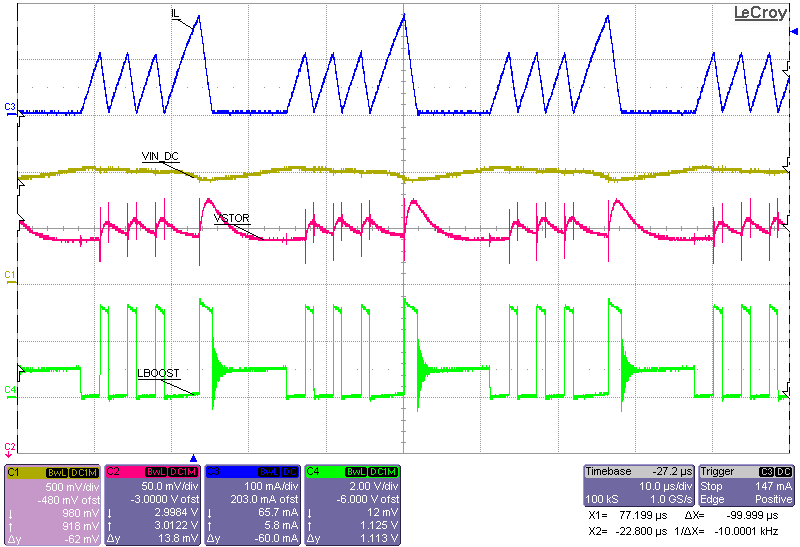

| IL = inductor current |

| VIN_DC = sourcemeter with VSOURCE = 2.0 V and compliance of 43 mA |

| VBAT = sourcemeter with VSOURCE = 3.6 V and compliance

of 1 A |

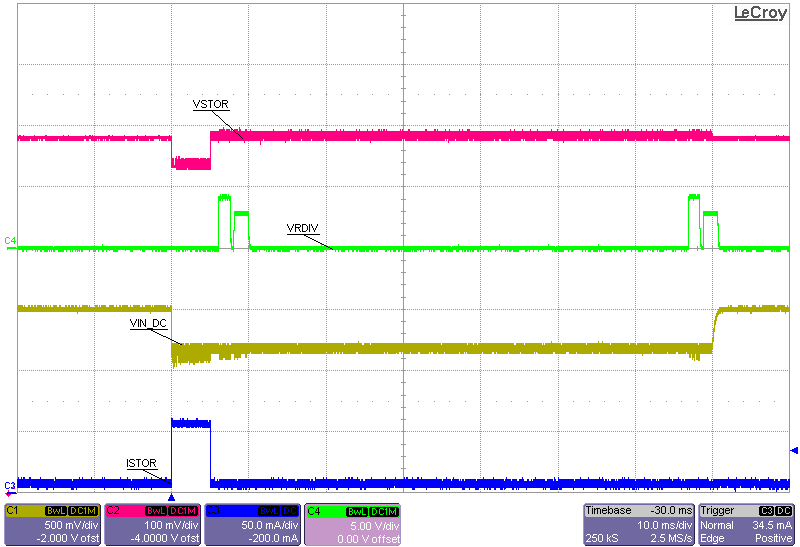

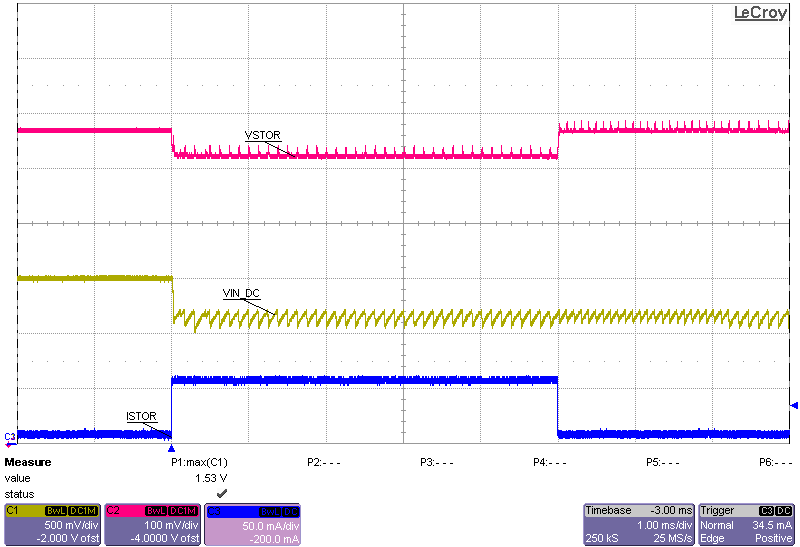

| VIN_DC = 1.5 V with 75 Ω series resistance |

| VBAT = 4.2 V charged 0.5 F capacitor |

| R(VSTOR) = open to 84 Ω to open |

| VIN_DC = source meter with 1.2 V compliance and ISC = 1.0 mA |

| 120 mF super capacitor on VBAT |