SLOSE84B August 2022 – October 2023 DRV8452

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Interface of Operation

- 7.3.2 Stepper Motor Driver Current Ratings

- 7.3.3 PWM Motor Drivers

- 7.3.4 Microstepping Indexer

- 7.3.5 Indexer Output

- 7.3.6 Automatic Microstepping Mode

- 7.3.7 Custom Microstepping Table

- 7.3.8 Current Regulation

- 7.3.9 Standstill Power Saving Mode

- 7.3.10 Current Regulation Decay Modes

- 7.3.11 Current Sensing with External Resistor

- 7.3.12 Silent step decay mode

- 7.3.13 Auto-torque Dynamic Current Adjustment

- 7.3.14 Charge Pump

- 7.3.15 Linear Voltage Regulator

- 7.3.16 VCC Voltage Supply

- 7.3.17 Logic Level, Tri-Level and Quad-Level Pin Diagrams

- 7.3.18 Spread Spectrum

- 7.3.19

Protection Circuits

- 7.3.19.1 VM Undervoltage Lockout

- 7.3.19.2 VCP Undervoltage Lockout (CPUV)

- 7.3.19.3 Logic Supply Power on Reset (POR)

- 7.3.19.4 Overcurrent Protection (OCP)

- 7.3.19.5 Stall Detection

- 7.3.19.6 Open-Load Detection (OL)

- 7.3.19.7 Overtemperature Warning (OTW)

- 7.3.19.8 Thermal Shutdown (OTSD)

- 7.3.19.9 Supply voltage sensing

- 7.3.19.10 nFAULT Output

- 7.3.19.11 Fault Condition Summary

- 7.3.20 Device Functional Modes

- 7.4 Programming

- 7.5

Register Maps

- 7.5.1 Status Registers

- 7.5.2

Control Registers

- 7.5.2.1 CTRL1 (address = 0x04) [Default = 0Fh]

- 7.5.2.2 CTRL2 (address = 0x05) [Default = 06h]

- 7.5.2.3 CTRL3 (address = 0x06) [Default = 38h]

- 7.5.2.4 CTRL4 (address = 0x07) [Default = 49h]

- 7.5.2.5 CTRL5 (address = 0x08) [Default = 03h]

- 7.5.2.6 CTRL6 (address = 0x09) [Default = 20h]

- 7.5.2.7 CTRL7 (address = 0x0A) [Default = FFh]

- 7.5.2.8 CTRL8 (address = 0x0B) [Default = 0Fh]

- 7.5.2.9 CTRL9 (address = 0x0C) [Default = 10h]

- 7.5.2.10 CTRL10 (address = 0x0D) [Default = 80h]

- 7.5.2.11 CTRL11 (address = 0x0E) [Default = FFh]

- 7.5.2.12 CTRL12 (address = 0x0F) [Default = 20h]

- 7.5.2.13 CTRL13 (address = 0x10) [Default = 10h]

- 7.5.3 Indexer Registers

- 7.5.4

Custom Microstepping Registers

- 7.5.4.1 CUSTOM_CTRL1 (address = 0x16) [Default = 00h]

- 7.5.4.2 CUSTOM_CTRL2 (address = 0x17) [Default = 00h]

- 7.5.4.3 CUSTOM_CTRL3 (address = 0x18) [Default = 00h]

- 7.5.4.4 CUSTOM_CTRL4 (address = 0x19) [Default = 00h]

- 7.5.4.5 CUSTOM_CTRL5 (address = 0x1A) [Default = 00h]

- 7.5.4.6 CUSTOM_CTRL6 (address = 0x1B) [Default = 00h]

- 7.5.4.7 CUSTOM_CTRL7 (address = 0x1C) [Default = 00h]

- 7.5.4.8 CUSTOM_CTRL8 (address = 0x1D) [Default = 00h]

- 7.5.4.9 CUSTOM_CTRL9 (address = 0x1E) [Default = 00h]

- 7.5.5

Auto torque Registers

- 7.5.5.1 ATQ_CTRL1 (address = 0x1F) [Default = 00h]

- 7.5.5.2 ATQ_CTRL2 (address = 0x20) [Default = 00h]

- 7.5.5.3 ATQ_CTRL3 (address = 0x21) [Default = 00h]

- 7.5.5.4 ATQ_CTRL4 (address = 0x22) [Default = 20h]

- 7.5.5.5 ATQ_CTRL5 (address = 0x23) [Default = 00h]

- 7.5.5.6 ATQ_CTRL6 (address = 0x24) [Default = 00h]

- 7.5.5.7 ATQ_CTRL7 (address = 0x25) [Default = 00h]

- 7.5.5.8 ATQ_CTRL8 (address = 0x26) [Default = 00h]

- 7.5.5.9 ATQ_CTRL9 (address = 0x27) [Default = 00h]

- 7.5.5.10 ATQ_CTRL10 (address = 0x28) [Default = 08h]

- 7.5.5.11 ATQ_CTRL11 (address = 0x29) [Default = 0Ah]

- 7.5.5.12 ATQ_CTRL12 (address = 0x2A) [Default = FFh]

- 7.5.5.13 ATQ_CTRL13 (address = 0x2B) [Default = 05h]

- 7.5.5.14 ATQ_CTRL14 (address = 0x2C) [Default = 0Fh]

- 7.5.5.15 ATQ_CTRL15 (address = 0x2D) [Default = 00h]

- 7.5.5.16 ATQ_CTRL16 (address = 0x2E) [Default = FFh]

- 7.5.5.17 ATQ_CTRL17 (address = 0x2F) [Default = 00h]

- 7.5.5.18 ATQ_CTRL18 (address = 0x30) [Default = 00h]

- 7.5.6 Silent Step Registers

- 8 Application and Implementation

- 9 Thermal Considerations

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

Orderable Information

7.3.13.1 Auto-torque Learning Routine

In a stepper motor system, the total power delivered by the power supply goes into providing for the torque requirement of the load and into power losses such as resistive losses caused by motor winding resistance and driver ON resistance. This is represented by Equation 11:

where τ is load torque and ω is motor speed.

From Equation 11, we can observe that when the load torque increases, the power delivered by the supply increases as well. The auto-torque algorithm obtains information about the load-torque by monitoring the power delivered by the supply. The constant losses are represented by the ATQ_LRN parameter, and the ATQ_CNT parameter represents the power required to support the load torque.

For any given motor, ATQ_LRN is directly proportional to the coil current. This can be expressed by Equation 12:

where IM is the motor current, VVM is the supply voltage to the driver and k is a constant. Equation 12 gives a linear relationship between the ATQ_LRN and the motor current. The auto-torque learning routine learns ATQ_LRN values at any two currents at no load, and then uses this relation to interpolate ATQ_LRN value at any other current.

The ATQ_CNT parameter represents the component of the delivered power that supports the load torque. This relation can be expressed by Equation 13.

where k1 is a constant at a given operating condition and IFS is the full-scale current (peak of the sinusoidal current waveform) of the stepper driver.

Equation 13 defines the basic working principle of the auto-torque algorithm. The ATQ_CNT parameter can be used to perform motor coil current regulation based on applied load torque on the stepper motor.

Figure 7-25 shows (ATQ_LRN + ATQ_CNT) measured as a function of load torque at 2.5A full-scale current for a hybrid bipolar NEMA 24 stepper motor rated for 2.8A. ATQ_LRN does not change with load torque, whereas ATQ_CNT changes linearly with load torque.

Figure 7-25 (ATQ_LRN + ATQ_CNT) vs. load torque

Figure 7-25 (ATQ_LRN + ATQ_CNT) vs. load torqueAfter auto-torque algorithm is enabled, the learning routine must be run to estimate the ATQ_LRN parameters.

The learning routine uses the linear relation between ATQ_LRN and motor current described in Equation 12. The user has to select two current values at which learning will be performed, with no load torque applied on the motor. These two current values are programmed by the ATQ_LRN_MIN_CURRENT and ATQ_LRN_STEP registers.

Initial current level = ATQ_LRN_MIN_CURRENT x 8

Final current level = Initial current level + ATQ_LRN_STEP

The ATQ_LRN values at these two currents are saved in the ATQ_LRN_CONST1 and ATQ_LRN_CONST2 registers. These two registers are used to interpolate ATQ_LRN value for all other currents within the operating range of the application.

Table 7-24 lists the registers associated with auto-torque learning routine.

Register Name | Description |

|---|---|

ATQ_LRN_MIN_CURRENT[4:0] | Represents the initial current level for auto-torque learning routine. |

ATQ_LRN_STEP[1:0] | Represents the increment to initial current level. It supports four options -

Example : If ATQ_LRN_STEP = 10b and ATQ_LRN_MIN_CURRENT = 11000b, then -

|

ATQ_LRN_CYCLE_SELECT[1:0] | Represents the number of electrical half cycles spent in one current level after which the learning routine allows the current to jump to the other level. It supports four options -

|

LRN_START | Writing 1b to this bit enables the auto-torque learning routine. After learning is completed, this bit automatically goes to 0b. |

LRN_DONE | This bit becomes 1b after learning is complete. |

ATQ_LRN_CONST1[10:0] | Indicates the ATQ_LRN parameter at the initial learning current level. |

ATQ_LRN_CONST2[10:0] | Indicates the ATQ_LRN parameter at the final learning current level. |

VM_SCALE | When this bit is 1b, the auto-torque algorithm automatically adjusts the ATQ_UL, ATQ_LL and ATQ_LRN parameters as per the supply voltage variation. |

Here are few points to consider while setting up the learning routine parameters:

It is recommended to select the initial current level between 30% to 50% of the maximum operating current.

Final current level must not exceed 255 and can be selected between 80% and 100% of the maximum operating current.

Current waveform distortions (due to high speed or low supply voltage) can cause incorrect reading of the ATQ_LRN parameters. The learning current levels should be chosen away from the currents where waveform distortions are observed.

Low values of ATQ_LRN_CYCLE_SELECT result in quicker learning. However, in systems prone to noise, higher ATQ_LRN_CYCLE_SELECT can result in more stable ATQ_LRN parameter values.

Learning should be done when the motor attains the steady-state speed.

Re-learning should be done if the motor is changed, or the motor speed changes by ± 10%.

For a quick summary, following sequence of commands should be applied to enable automatic learning:

Write 1b to ATQ_EN

Run the motor with no load

Program ATQ_LRN_MIN_CURRENT

Program ATQ_LRN_STEP

Program ATQ_LRN_CYCLE_SELECT

Write 1b to ATQ_LRN_START

The algorithm runs the motor with initial current level for ATQ_LRN_CYCLE_SELECT number of electrical half cycles

Next, the algorithm runs the motor with final current level for ATQ_LRN_CYCLE_SELECT number of electrical half cycles

After learning is complete,

ATQ_LRN_START bit is auto cleared to 0b

ATQ_LRN_DONE bit becomes 1b

ATQ_LRN_CONST1 and ATQ_LRN_CONST2 are populated in their respective registers

Motor current goes to ATQ_TRQ_MAX

Once the ATQ_LRN_CONST1 and ATQ_LRN_CONST2 are known from the prototyping tests, they can be used for mass production without invoking the learning routine again. The following sequence of commands should be applied in mass production:

VREF set to the same value as during learning in prototype tests

Program ATQ_LRN_MIN_CURRENT

Program ATQ_LRN_STEP

Program ATQ_LRN_CONST1

Program ATQ_LRN_CONST2

Write 1b to ATQ_EN

Figure 7-26 shows the consolidated flowchart of the auto-torque learning routine.

Figure 7-26 Auto-torque Learning Flowchart

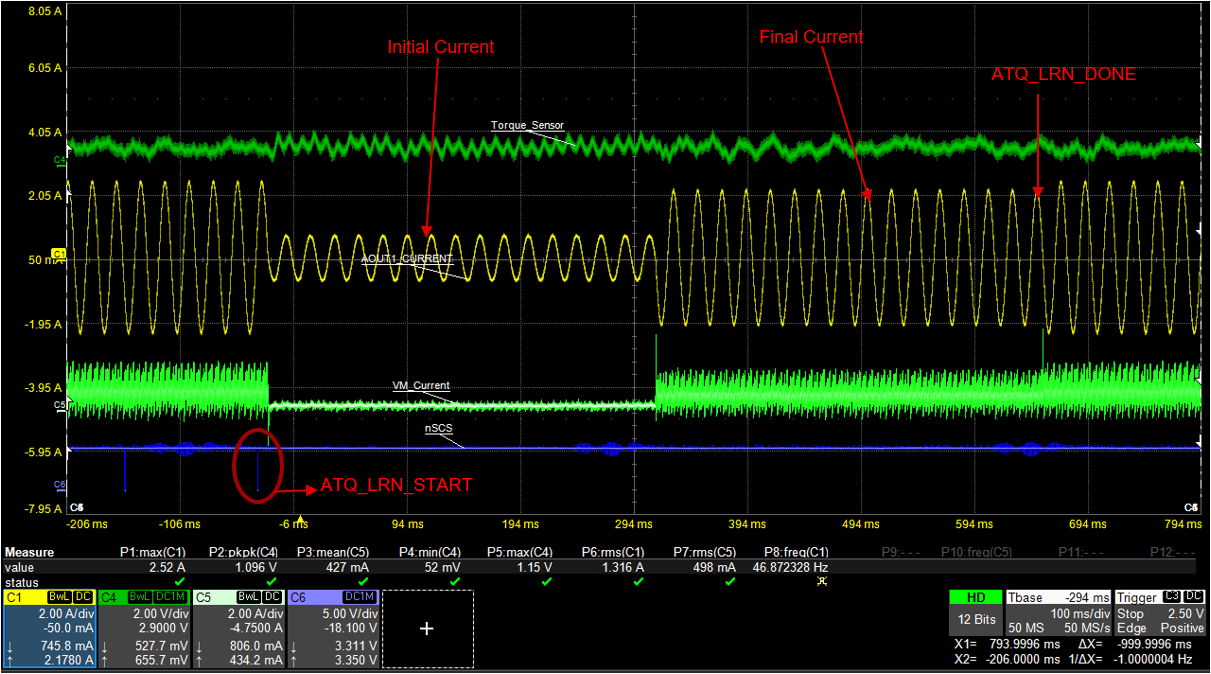

Figure 7-26 Auto-torque Learning Flowchart Figure 7-27 Auto-torque learning

Figure 7-27 Auto-torque learningFigure 7-27 shows an automatic learning process with 740 mA initial current (IFS1) and 2.2 A final current (IFS2). The ATQ_LEARN_CYCLE_SELECT corresponds to 32 half-cycles.