SLUSCO8B November 2016 – June 2018 TPS54200 , TPS54201

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Description (continued)

- 6 Pin Configuration and Functions

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3 Feature Description

- 8.4 Device Functional Modes

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DDC|6

Thermal pad, mechanical data (Package|Pins)

Orderable Information

9.2.1.3 Application Curves

| CH2: SW | CH3: LED current | CH4: Inductor current |

| (AC-coupled) |

| CH1: PWM | CH3: Inductor current | CH4: LED current |

Changes From 1% to 99%

| CH1: PWM | CH3: Inductor current | CH4: LED current |

Changes From 99% to 1%

| CH1: PWM | CH2: SW | CH3: VOUT | CH4: LED current |

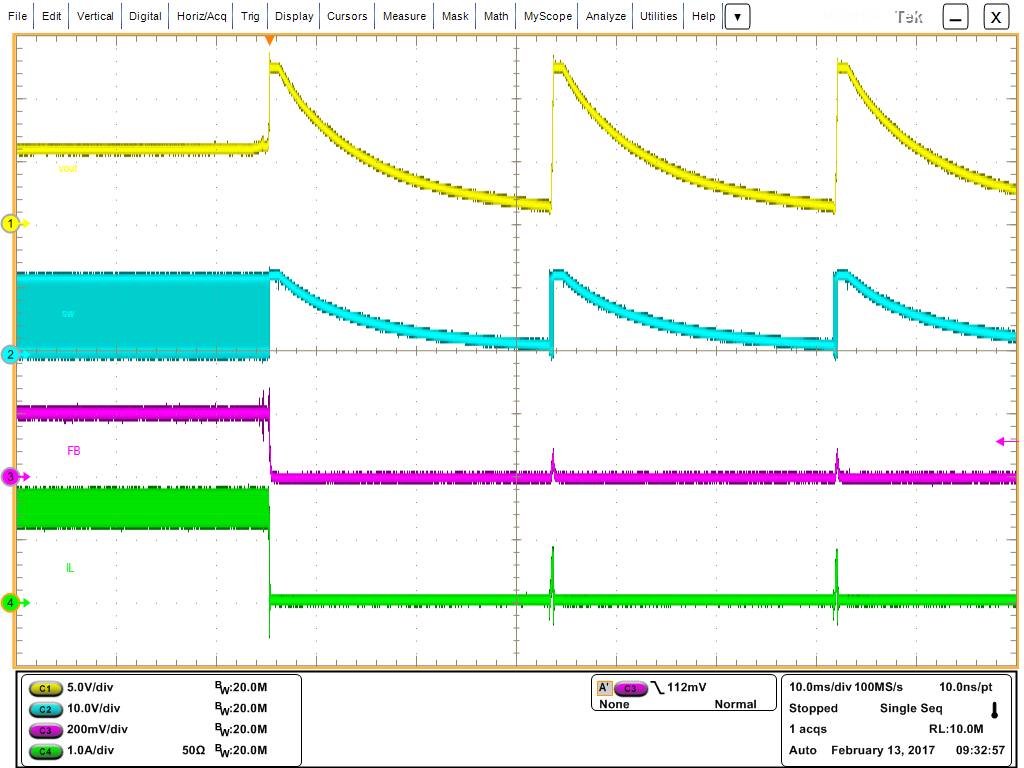

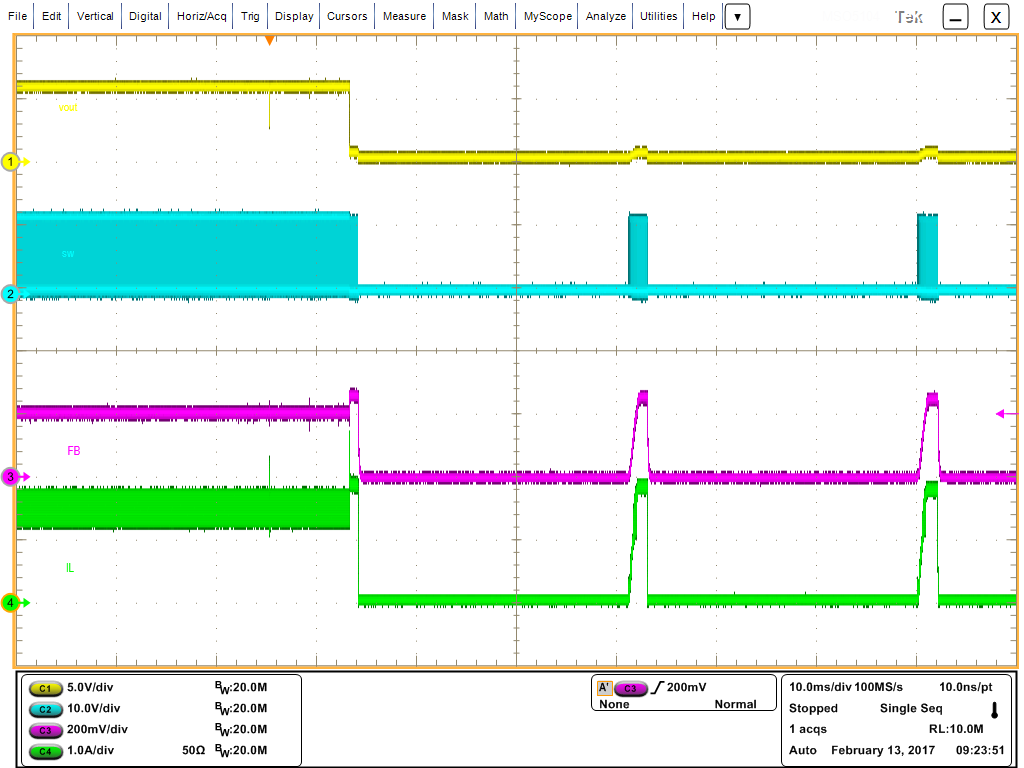

| CH1: VOUT | CH2: SW | CH3: FB | CH4: Inductor current |

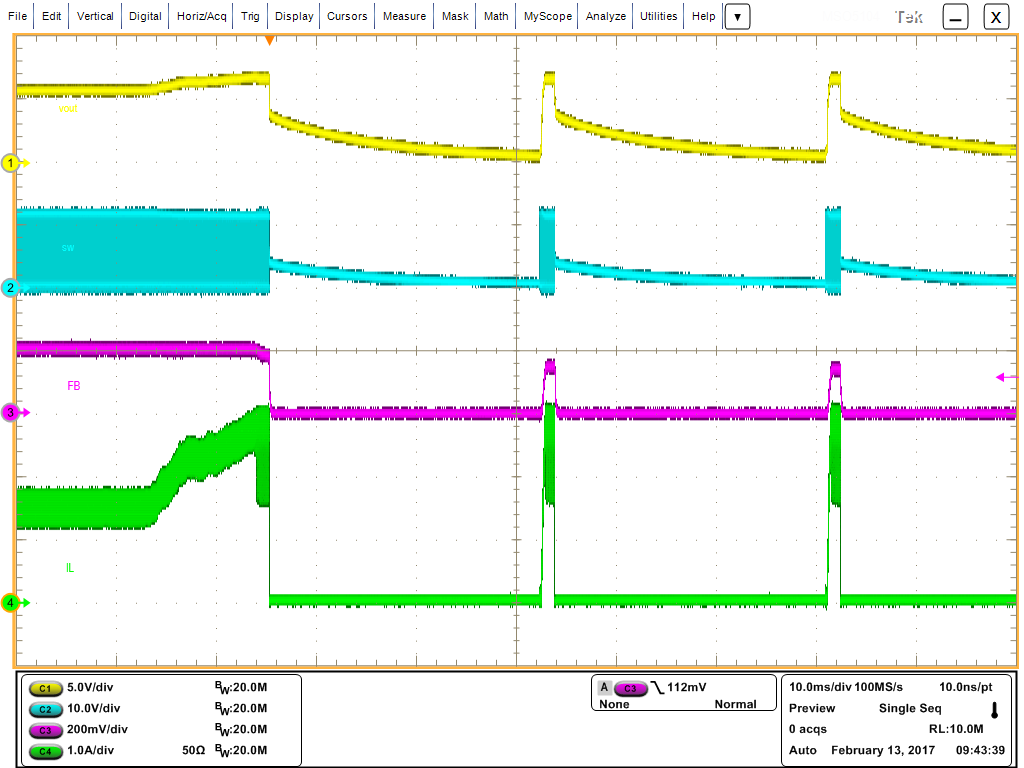

| CH1: VOUT | CH2: SW | CH3: FB | CH4: Inductor current |

| CH1: VOUT | CH2: SW | CH3: FB | CH4:Inductor current |

| CH2: SW | CH3: LED current | CH4: Inductor current |

| (AC-coupled) |

| CH1: VVIN | CH2: SW | CH4: Inductor current |

| (AC-coupled) |

| CH1: PWM | CH3: Inductor current | CH4: LED current |

Changes From 50% to 99%

| CH1: PWM | CH2: SW | CH3: VOUT | CH4: LED current; |

| CH1: PWM | CH2: SW | CH3: VOUT | CH4: LED current |

1.

Figure 35. LED Short Protection (100% PWM Duty Cycle) of TPS54201

| CH1: VOUT | CH2: SW | CH3: FB | CH4: Inductor current |