SLVSEW6F August 2021 – March 2024 TPS7H2211-SEP , TPS7H2211-SP

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Device Options

- 5 Related Products

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics: All Devices

- 7.6 Electrical Characteristics: CFP and KGD Options

- 7.7 Electrical Characteristics: HTSSOP Option

- 7.8 Switching Characteristics: All Devices

- 7.9 Quality Conformance Inspection

- 7.10 Typical Characteristics

- 8 Parameter Measurement Information

- 9 Detailed Description

- 10Application and Implementation

- 11Device and Documentation Support

- 12Revision History

- 13Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DAP|32

- KGD|0

- HKR|16

Thermal pad, mechanical data (Package|Pins)

- DAP|32

Orderable Information

8 Parameter Measurement Information

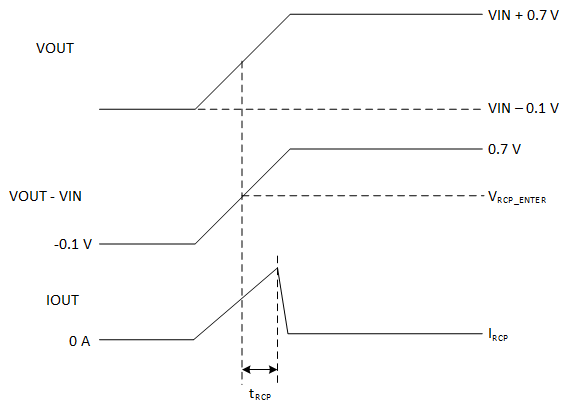

A. VIN is held constant during the test.

B. VRCP_ENTER is referenced from VOUT to VIN. It is the

threshold that, when reached, will turn-off the main switch FETs to prevent

reverse current flow.

Figure 8-1 Reverse Current Protection

Enter (VRCP_ENTER) Test Waveforms

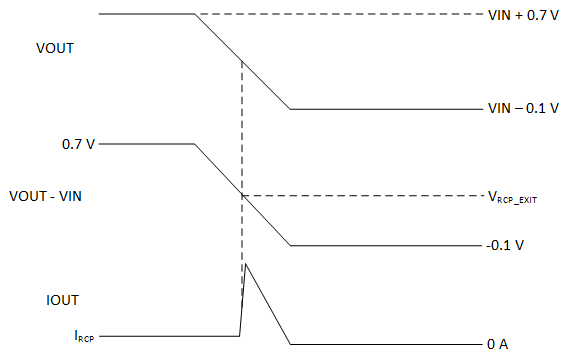

A. VIN is held constant during the test.

B. VRCP_EXIT is referenced from VOUT to VIN. It is the

threshold that, when reached, will turn-off the reverse current protection

feature.

Figure 8-2 Reverse Current Protection

Exit (VRCP_EXIT) Test Waveforms Figure 8-3 EN Signal Low Time to

Restart Device (tLOW_OFF)

Figure 8-3 EN Signal Low Time to

Restart Device (tLOW_OFF) Figure 8-4 Turn-On Time (tON), Turn-Off Time (tOFF), and VOUT

Fall Time (tF) Waveforms

Figure 8-4 Turn-On Time (tON), Turn-Off Time (tOFF), and VOUT

Fall Time (tF) Waveforms

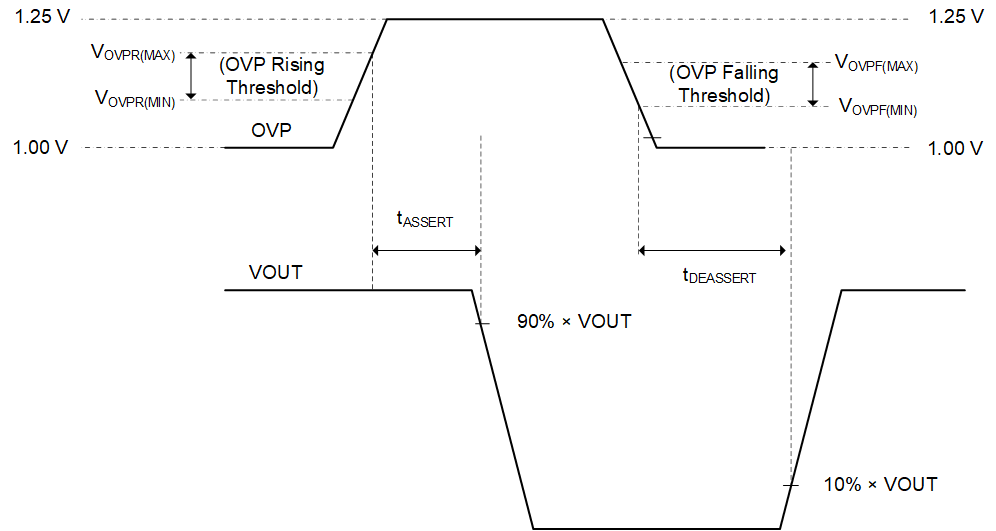

A. The OVP test signal uses a

typical rise time and fall time of 30 ns.

Figure 8-5 OVP Assert

(tASSERT) and OVP Deassert (tDEASSERT)

Waveforms