SLUSEV2C June 2022 – March 2023 UCC28C50-Q1 , UCC28C51-Q1 , UCC28C52-Q1 , UCC28C53-Q1 , UCC28C54-Q1 , UCC28C55-Q1 , UCC28C56H-Q1 , UCC28C56L-Q1 , UCC28C57H-Q1 , UCC28C57L-Q1 , UCC28C58-Q1 , UCC28C59-Q1

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3 Feature Description

- 8.4 Device Functional Modes

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical Application

- 9.2.1 Design Requirements

- 9.2.2

Detailed Design Procedure

- 9.2.2.1 Primary-to-Secondary Turns Ratio of the Flyback Transformer (NPS)

- 9.2.2.2 Primary Magnetizing Inductance of the Flyback Transformer (LM)

- 9.2.2.3 Number of Turns of the Flyback Transformer Windings

- 9.2.2.4 Current Sense Resistors (R24, R25) and Current Limiting

- 9.2.2.5 Primary Clamp Circuit (D7, D1, D3, R2, R28) to Limit Voltage Stress

- 9.2.2.6 Primary-Side Current Stress and Input Capacitor Selection

- 9.2.2.7 Secondary-Side Current Stress and Output Capacitor Selection

- 9.2.2.8 VDD Capacitors (C12, C18)

- 9.2.2.9 Gate Drive Network (R14, R16, Q6)

- 9.2.2.10 VREF Capacitor (C18)

- 9.2.2.11 RT/CT Components (R12, C15)

- 9.2.2.12 HV Start-Up Circuitry for VDD (Q1, Q2, D2, D4, D6, D8, R5)

- 9.2.2.13 Desensitization to CS-pin Noise by RC Filtering, Leading-Edge Blanking, and Slope Compensation

- 9.2.2.14 Voltage Feedback Compensation

- 9.2.3 Application Curves

- 9.3 PCB Layout Recommendations

- 9.4 Power Supply Recommendations

- 10Device and Documentation Support

- 11Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- D|8

Thermal pad, mechanical data (Package|Pins)

Orderable Information

9.2.3 Application Curves

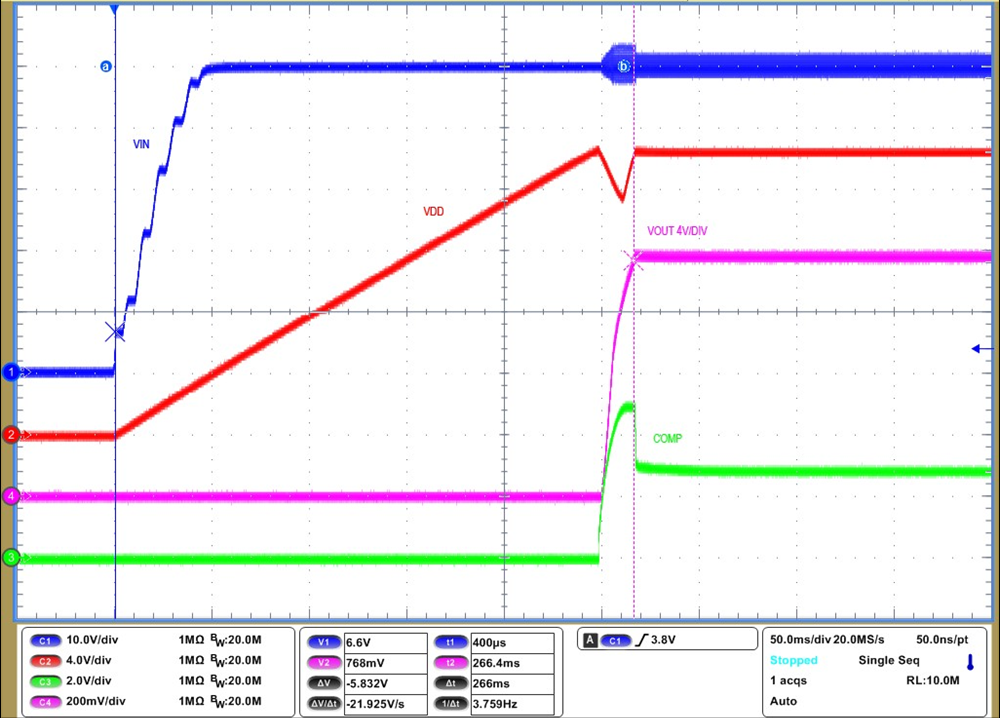

| VIN applied to VOUT ready in 266 ms |

| CH1: VIN at 10 V/DIV |

| CH2: VDD at 4 V/DIV |

| CH3: COMP at 2 V/DIV |

| CH4: VOUT at 4 V/DIV via differential probe |

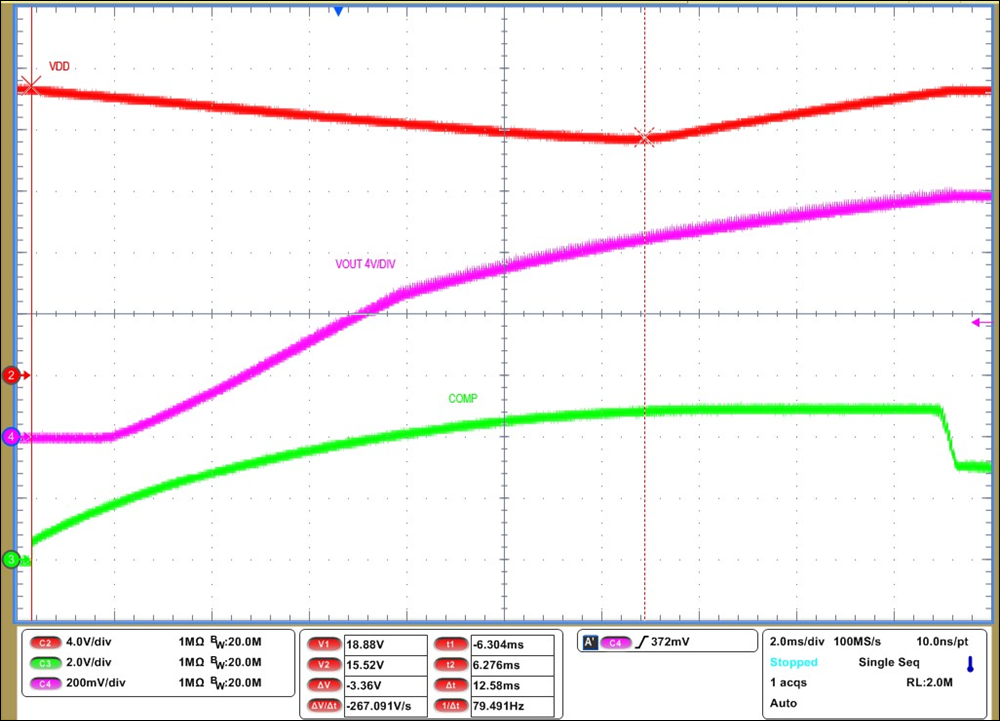

| VDD capacitor hold-up time = 12.6 ms |

| VOUT rise time = 17.2 ms |

| CH2: VDD at 4 V/DIV |

| CH3: COMP at 2V/DIV |

| CH4: VOUT at 4 V/DIV via differential probe |

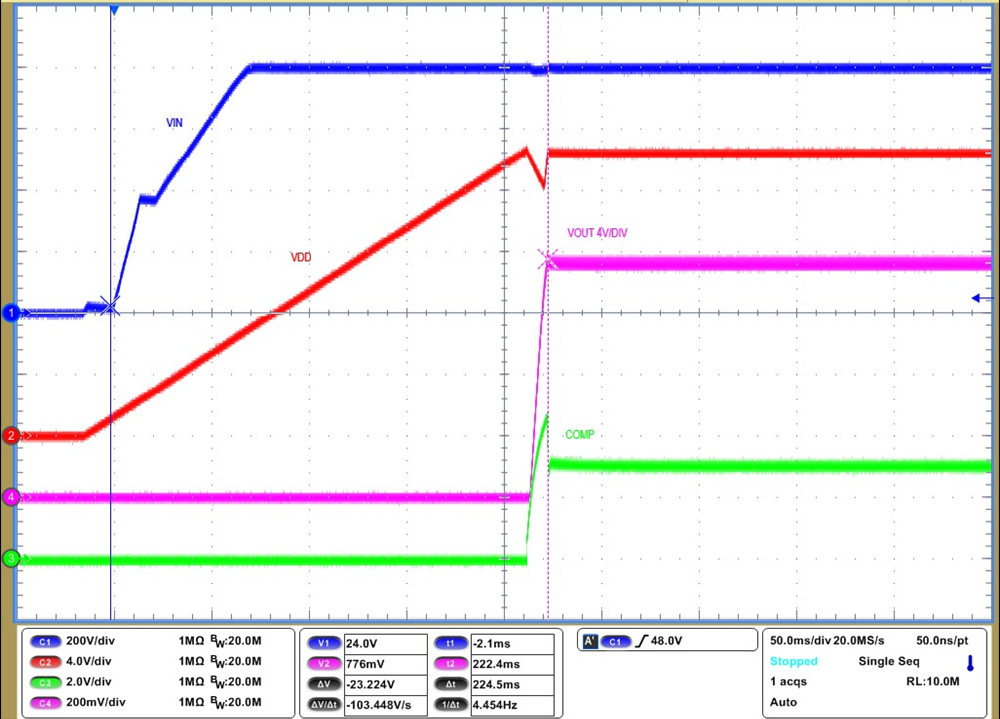

| VIN applied to VOUT ready in 224 ms |

| CH1: VIN at 200 V/DIV |

| CH2: VDD at 4 V/DIV |

| CH3: COMP at 2 V/DIV |

| CH4: VOUT at 4 V/DIV via differential probe |

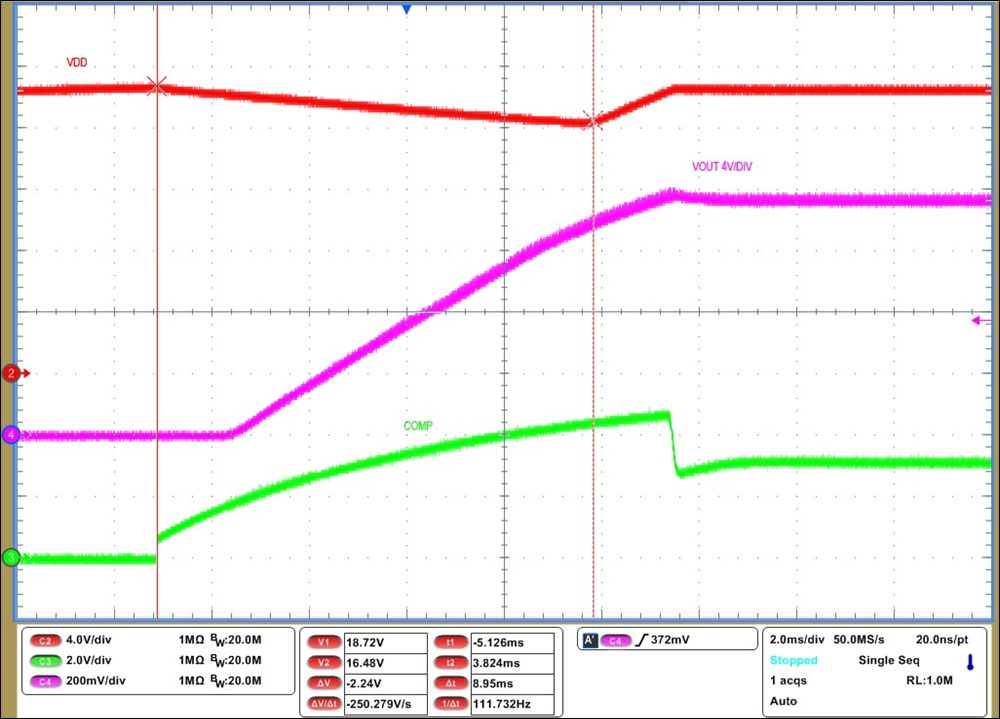

| VDD capacitor hold-up time = 8.9 ms |

| VOUT rise time = 9.1 ms |

| CH2: VDD at 4 V/DIV |

| CH3: COMP at 2V/DIV |

| CH4: VOUT at 4 V/DIV via differential probe |

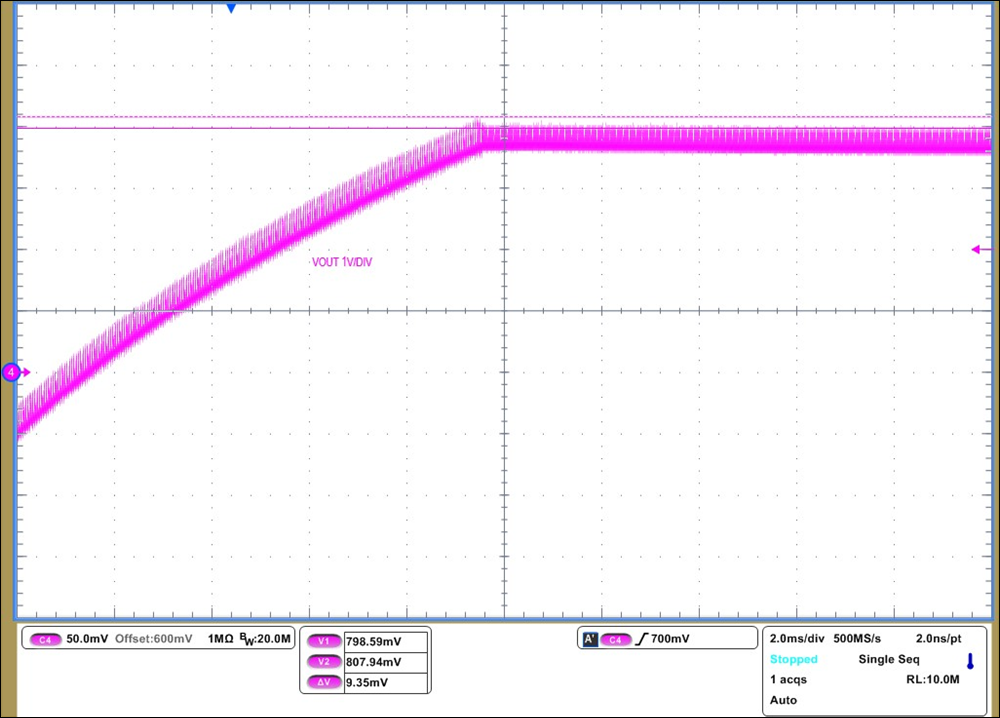

| Soft Start Overshoot = 1.2 % |

| CH4: VOUT at 1 V/DIV via differential probe |

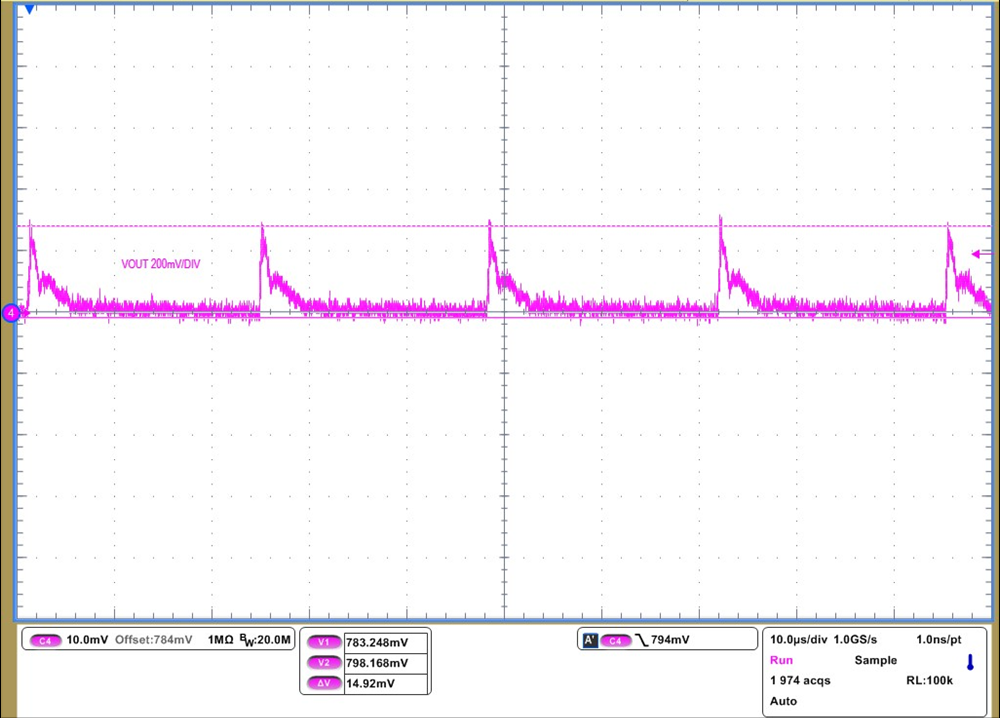

| Output Voltage Ripple = 298 mVPP |

| CH4: VOUT at 200 mV/DIV via differential probe |

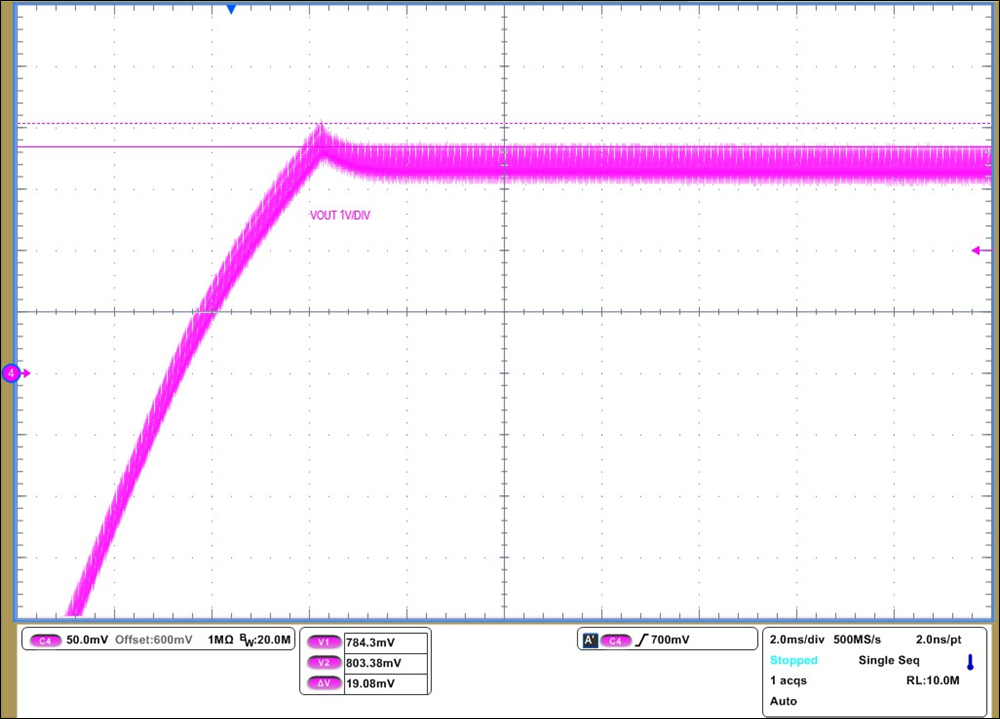

| Soft Start Overshoot = 2.4 % |

| CH4: VOUT at 1 V/DIV via differential probe |

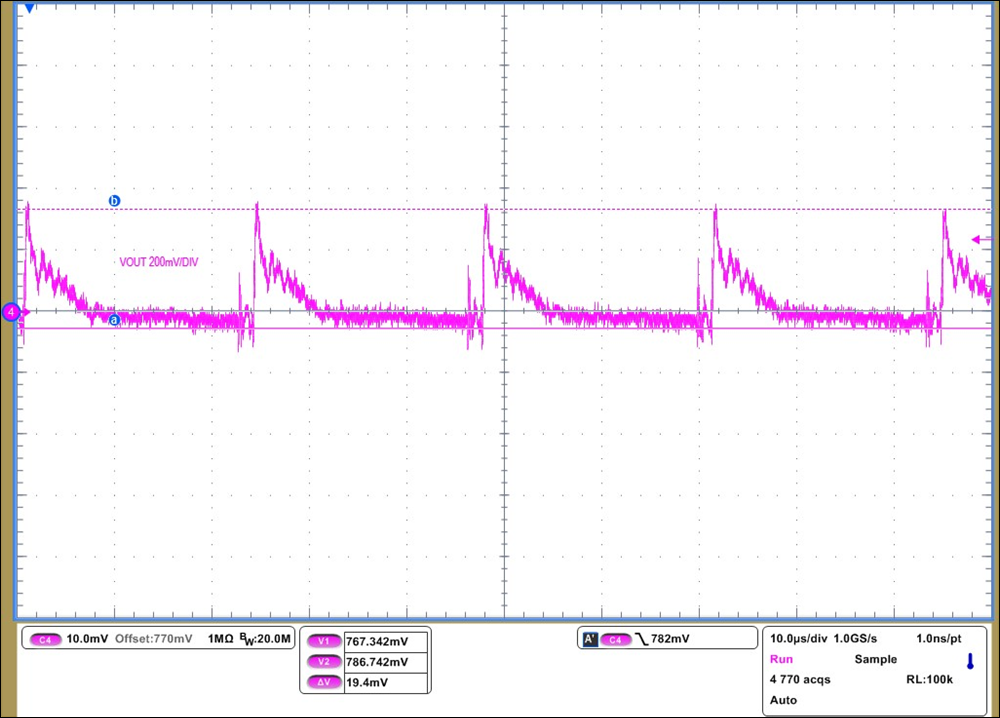

| Output Voltage Ripple = 388 mVPP |

| CH4: VOUT at 200 mV/DIV via differential probe |

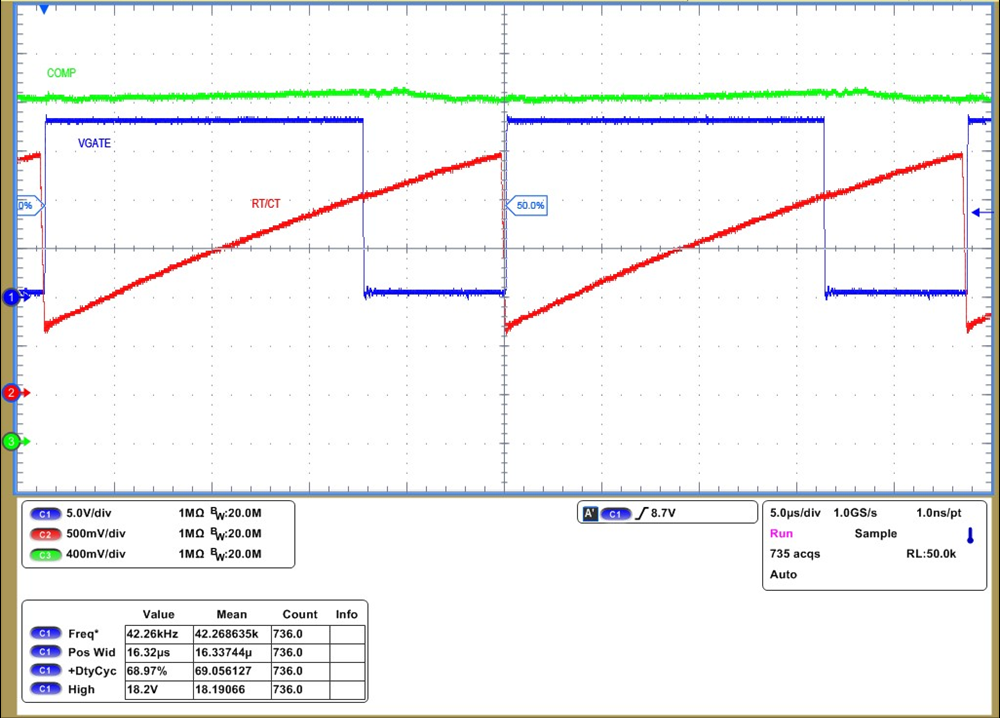

| fSW = 42.6 kHz, tON = 16.3 us, Duty Cycle = 69 % |

| CH1: VGATE at 5 V/DIV |

| CH2: RT/CT at 500 mV/DIV |

| CH3: COMP at 400 mV/DIV |

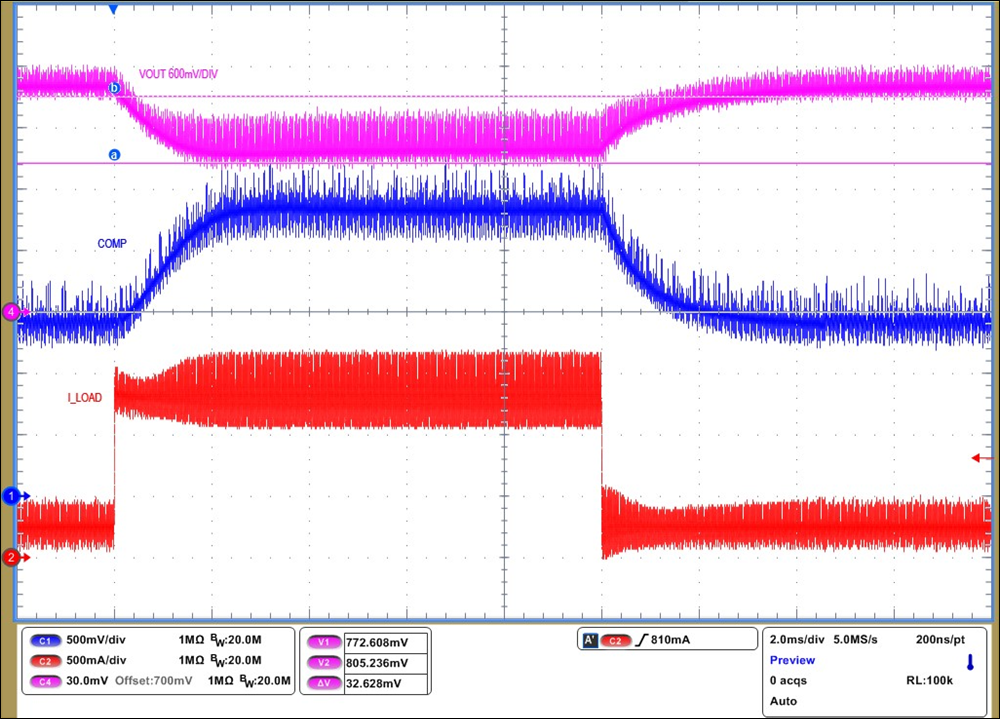

| 250 mA to 1.3 A to 250 mA |

| VMAX = 16.1 V, VMIN = 15.4 V, dV = 0.7 V |

| CH1: COMP at 50 mV/DIV |

| CH2: I_LOAD at 500 mA/DIV |

| CH4: VOUT at 600 mV/DIV via differential probe |

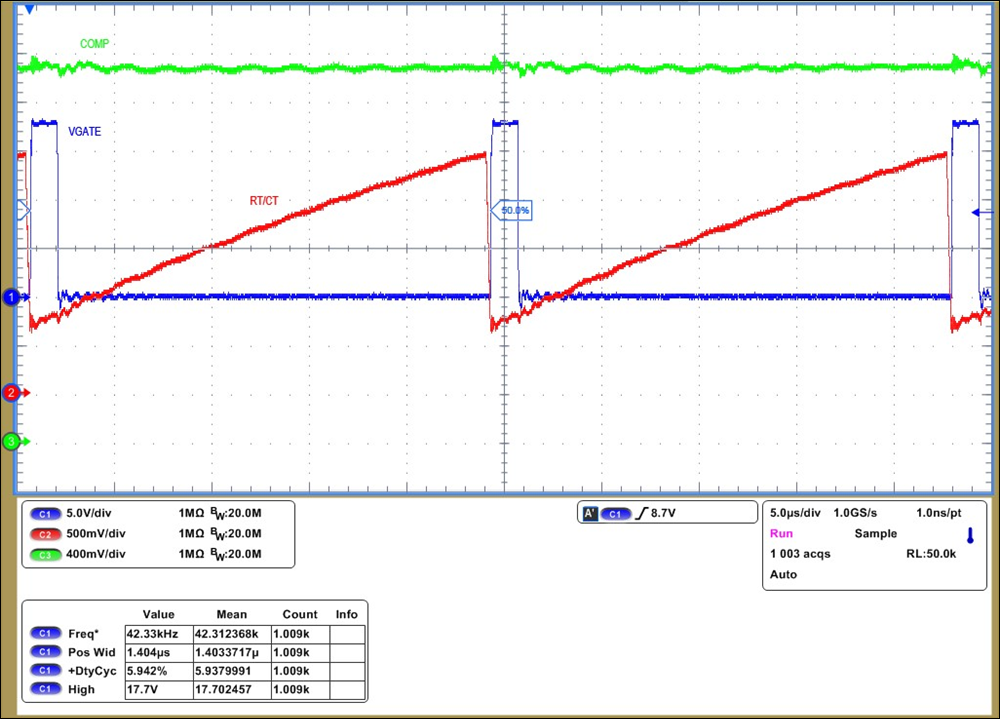

| fSW = 42.3 kHz, tON = 1.4 us, Duty Cycle = 5.9 % |

| CH1: VGATE at 5 V/DIV |

| CH2: RT/CT at 500 mV/DIV |

| CH3: COMP at 400 mV/DIV |

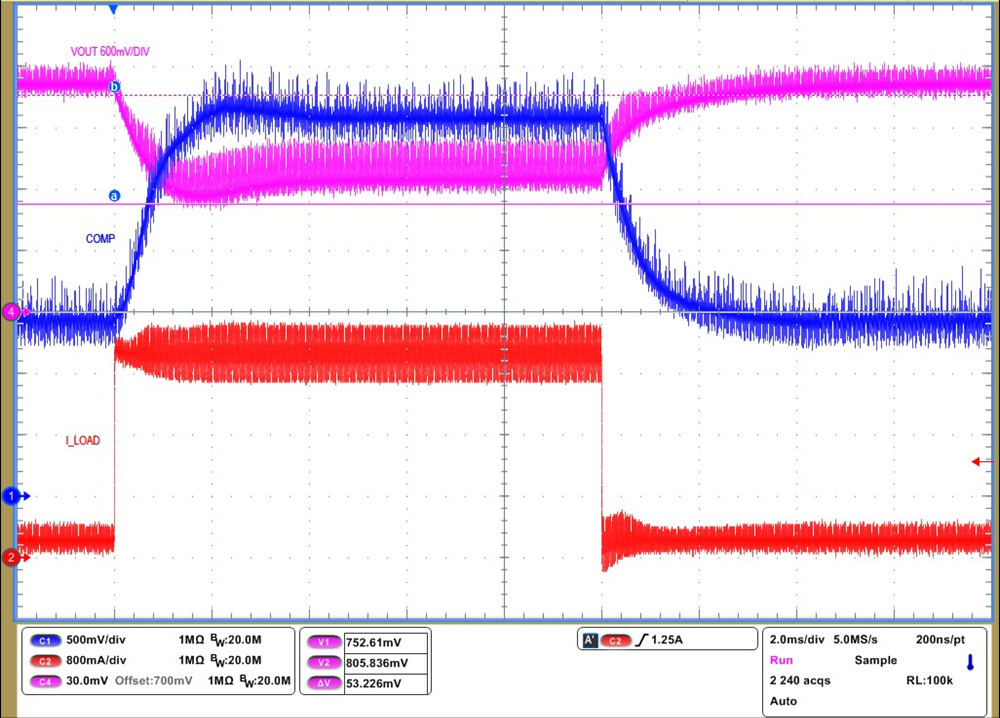

| 250 mA to 2.7 A to 250 mA |

| VMAX = 16.1 V, VMIN = 15.1V, dV = 1.0 V |

| CH1: COMP at 50 mV/DIV |

| CH2: I_LOAD at 800 mA/DIV |

| CH4: VOUT at 600 mV/DIV via differential probe |