JAJSHX1B September 2019 – July 2021 TMCS1100

PRODUCTION DATA

- 1 特長

- 2 アプリケーション

- 3 概要

- 4 Revision History

- 5 Device Comparison

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Parameter Measurement Information

- 9 Detailed Description

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

10.2 Typical Application

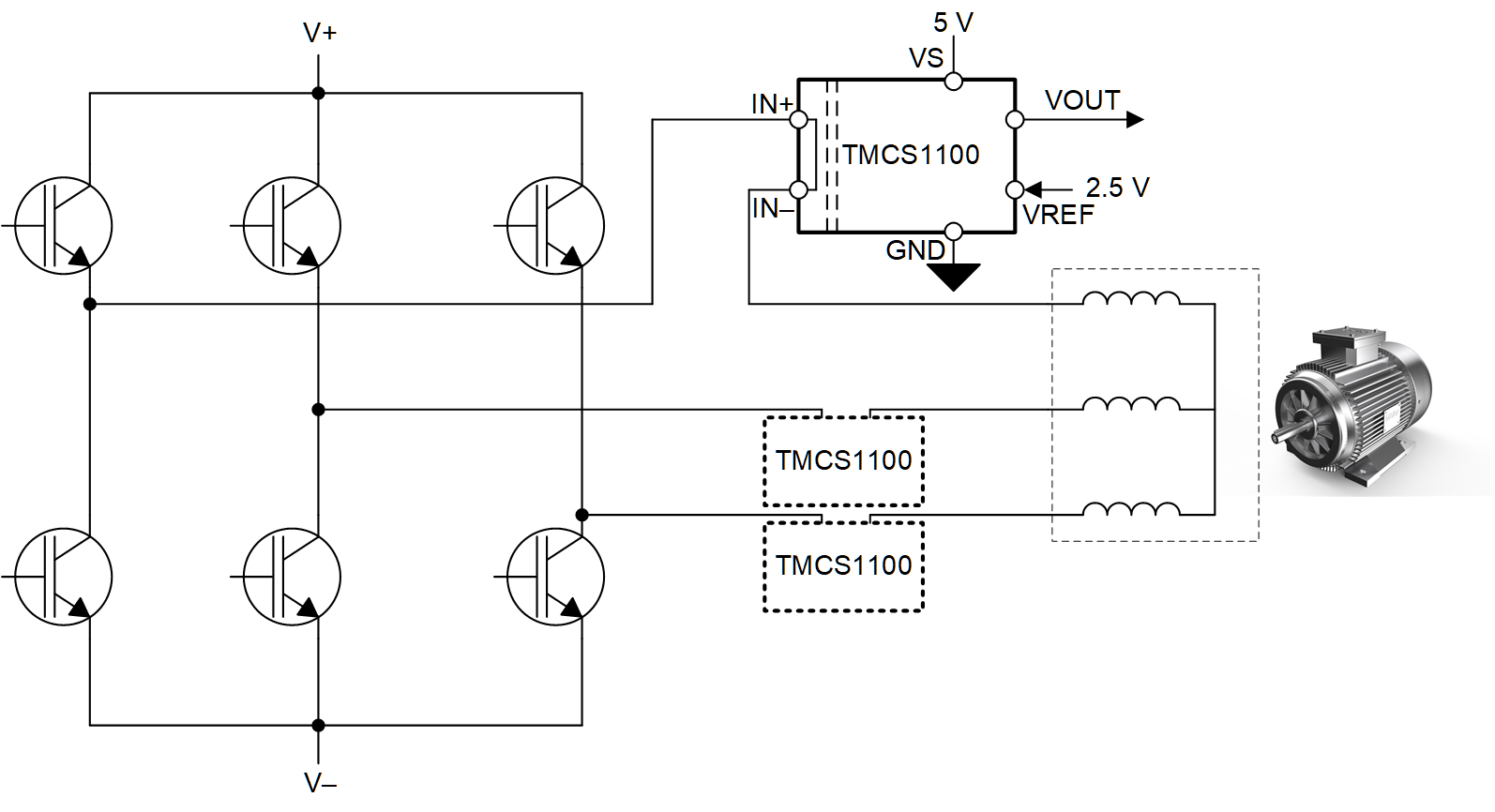

Inline sensing of inductive load currents, such as motor phases, provides significant benefits to the performance of a control systems, allowing advanced control algorithms and diagnostics with minimal postprocessing. A primary challenge to inline sensing is that the current sensor is subjected to full HV supply-level PWM transients driving the load. The inherent isolation of an in-package Hall-effect current sensor topology helps overcome this challenge, providing high common-mode immunity, as well as isolation between the high-voltage motor drive levels and the low-voltage control circuitry. Figure 10-2 illustrates the use of the TMCS1100 in such an application, driving the inductive load presented by a three phase motor.

Figure 10-2 Inline

Motor Phase Current Sensing

Figure 10-2 Inline

Motor Phase Current Sensing