SLVAER8A April 2020 – October 2020 TPS63900 , TPS63901

2 Case Study

Consider a wireless sensor system shown in Figure 1-1, with a load profile shown in Figure 2-1. In reality, the load profile is usually more complex, with a sequence of different pulses. For the sake of simplicity and without significantly affecting the results, here the load profile is represented with a single rectangular pulse.

The system performs measurements or detection continuously, and transmits the data four times per day. The battery used is a 3-V Li-MnO2 type, which is often the choice in long-life applications due to high energy density and low self-discharge. The converter provides the 3.6-V rail to power the system. In this case, the duty cycle D, defined as the time spent in high-power mode divided by the time spent in low-power mode, is close to 2·10-7.

Figure 2-1 Load

Current Consumption for the Case Study

Figure 2-1 Load

Current Consumption for the Case StudyWith such a load profile, the energy consumption of the measurement period is more than two times larger than the energy consumption of the transmission period. This means that the efficiency at light loads, therefore, a low IQ is more important than the efficiency at heavy loads.

Compare the TPS63900 with a closest competing device and see the difference in battery life. First, Table 2-1 shows the main parameters of these two devices.

| TPS63900 | Competitor | ||

|---|---|---|---|

| Quiescent current | 75 nA | 300 nA | |

| Input voltage range | 1.8 V - 5.5 V | 1.8 V – 5.5 V | |

| Output voltage range | 1.8 V - 5 V | 1.6 V - 5.2 V | |

| Maximum output current | > 400 mA | 250 mA | at VOUT = 3.6 V |

| Adjustable output voltage | Yes, 100-mV step | No | |

| Dynamic voltage scaling | Yes, 2-level | No | |

| Adjustable input current limit | Yes, 8 presets | No |

Compare the two devices in case the voltage rail is fixed. Table 2-2 shows that the 4 times lower IQ of the TPS63900 decreases the total charge per load cycle by 8%, which increases the battery life by 9% when compared to the competitor's device.

| Load Profile | TPS63900 | Competitor | ||||||

|---|---|---|---|---|---|---|---|---|

| IOUT [mA] | t [s] | VOUT [V] | Eff [%] | IIN [mA] | QIN [As] | Eff [%] | IIN [mA] | QIN [As] |

| 0.01 | 21600 | 3.6 | 92.5 | 1.3x10-5 | 0.281 | 82.1 | 1.46x10-5 | 0.316 |

| 250 | 0.4 | 3.6 | 92.3 | 0.325 | 0.130 | 91.7 | 0.327 | 0.131 |

| Total QIN [As] | 0.411 | 0.447 | ||||||

| Battery life extended [%] | 9 | |||||||

A 9% increase is not negligible when taking into account all the benefits of a longer battery life, such as the user experience or associated costs to replace the battery. Moreover, if the duty cycle is further decreased, or in this case if the transmission takes place less frequently, the advantage of having low IQ becomes more apparent.

Go a step further and see the benefits of having the option to dynamically change the system voltage. The TPS63900 has the possibility to switch between two user-configurable output voltages that are loaded into the device during startup. If the standby voltage is decreased to 2.1 V, the power consumption is cut to almost a half of the power consumption at 3.6 V. Table 2-3 shows the resulting battery life increase when compared to the competitor’s device that cannot dynamically change the output voltage.

| Load Profile | TPS63900 | ||||

|---|---|---|---|---|---|

| IOUT [mA] | t [s] | VOUT [V] | Eff [%] | IIN [mA] | QIN [As] |

| 0.01 | 21600 | 2.1 | 90.8 | 7.71x10-6 | 0.167 |

| 250 | 0.4 | 3.6 | 92.3 | 0.325 | 0.130 |

| Total QIN [As] | 0.297 | ||||

| Battery life extended [%] | 51 | ||||

It should be noted that in the above case it is assumed that the load current remains the same if the load voltage is scaled. This may be true for constant current types of load, such as LDOs. Many loads, such as microcontrollers or operational amplifiers for example, behave resistive-like, and will show lower power consumption at lower operating voltages. If in the previous case, it is assumed that the load current scales with the load voltage, Table 2-4 shows that the battery life can be extended by 86%, compared to the competitors device. Compared to the fixed system voltage case, dynamic voltage scaling can significantly extend the battery life.

| Load Profile | TPS63900 | ||||

|---|---|---|---|---|---|

| IOUT [mA] | t [s] | VOUT [V] | Eff [%] | IIN [mA] | QIN [As] |

| 0.0058 | 21600 | 2.1 | 80 | 5.1x10-6 | 0.110 |

| 250 | 0.4 | 3.6 | 92.3 | 0.325 | 0.130 |

| Total QIN [As] | 0.240 | ||||

| Battery life extended [%] | 86 | ||||

Besides the ultra-low quiescent current, one of the main features of the TPS63900 is the input current limiting. The TPS63900 can limit the current drawn from the input supply to protect the batteries that do not support high peak currents, such as coin cell batteries. The input current limit is active both during normal operation and during start-up. This is shown in more details in the Extend Battery Life Using a DC-DC Converter with Programmable Input Current Limit Technical Brief.

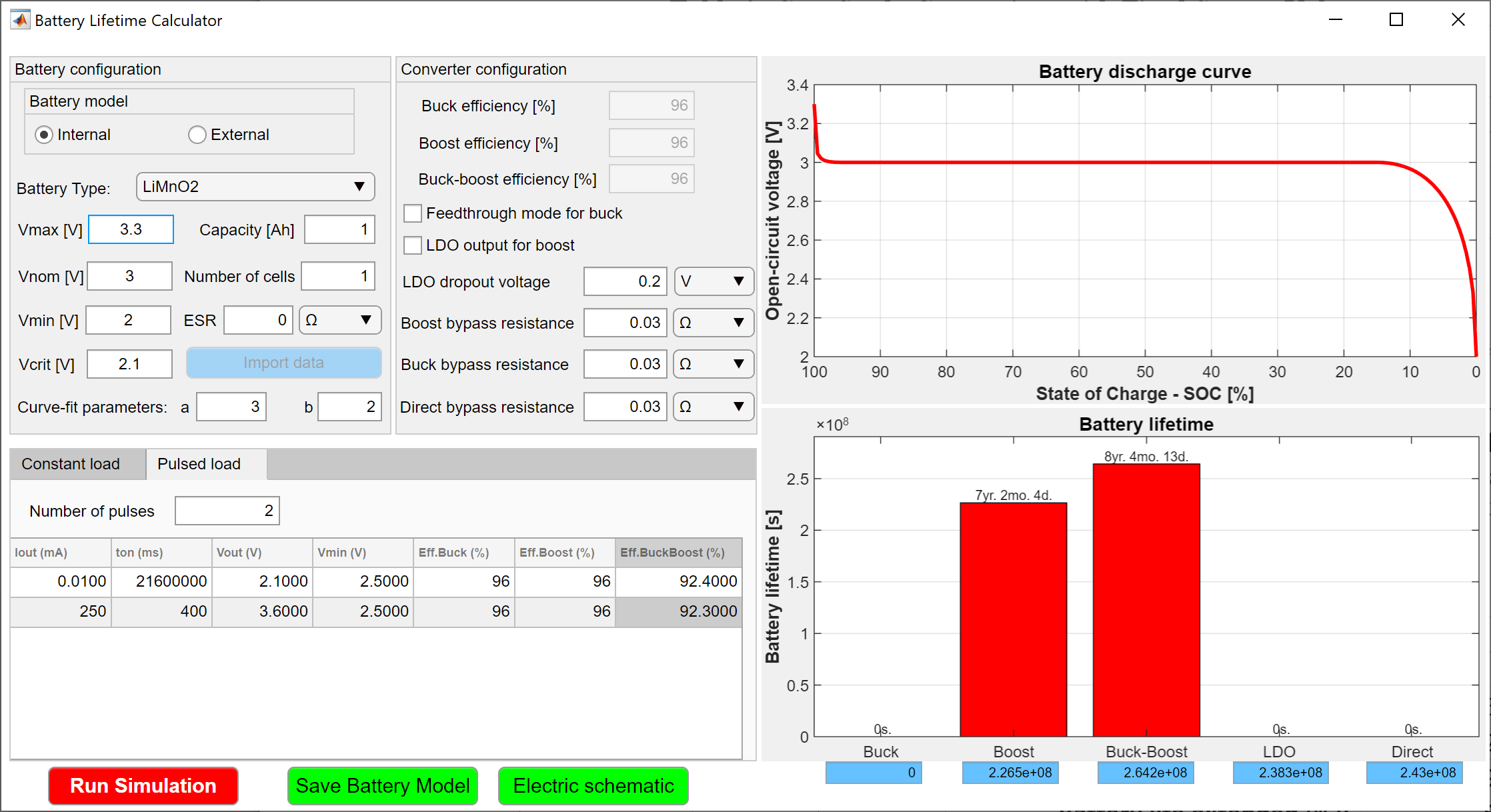

Estimating battery life for a specific scenario can be time consuming, especially when taking into account various parameters such as the battery characteristics, converter efficiency and load profiles. The “Battery Lifetime Calculator” tool can speed up and ease this process. Figure 2-2 shows the interface of the tool. Various scenarios can be tested by selecting the built-in or importing custom battery discharge curves, converter parameters and load profiles. Moreover, different converter topologies are compared to determine which one is the best match for the given case.

Figure 2-2 Tool for

Estimating Battery Life

Figure 2-2 Tool for

Estimating Battery Life