SLVAFO8A April 2024 – May 2024 DRV8214 , DRV8234

- 1

- Abstract

- Trademarks

- 1Introduction: Need for Sensorless Designs

- 2Ripple Counting − Concept

- 3Case Study: Robotic Wheel Drive

- 4Challenges and Workarounds

- 5Summary

- 6References

- 7Revision History

4.3 Inrush

This case covers possible workarounds for ripples missed during motor start-up due to inrush current as observed in Figure 3-2.

- Adjust the T_MECH_FLT register to match the system response time more accurately, as shown in Figure 3-3. The trade-off here is to sacrifice some accuracy during steady-state performance.

- Using current regulation during inrush time also helps the algorithm track ripples more accurately.

- If using internal speed or voltage regulation feature, enable soft-start and soft-stop (EN_SS = 1b).

- If using DRV8214, program the controller to change CS_GAIN_SEL dynamically when loading/unloading is expected in DRV8214. For more details on functionality of CS_GAIN_SEL, refer to the data sheet.

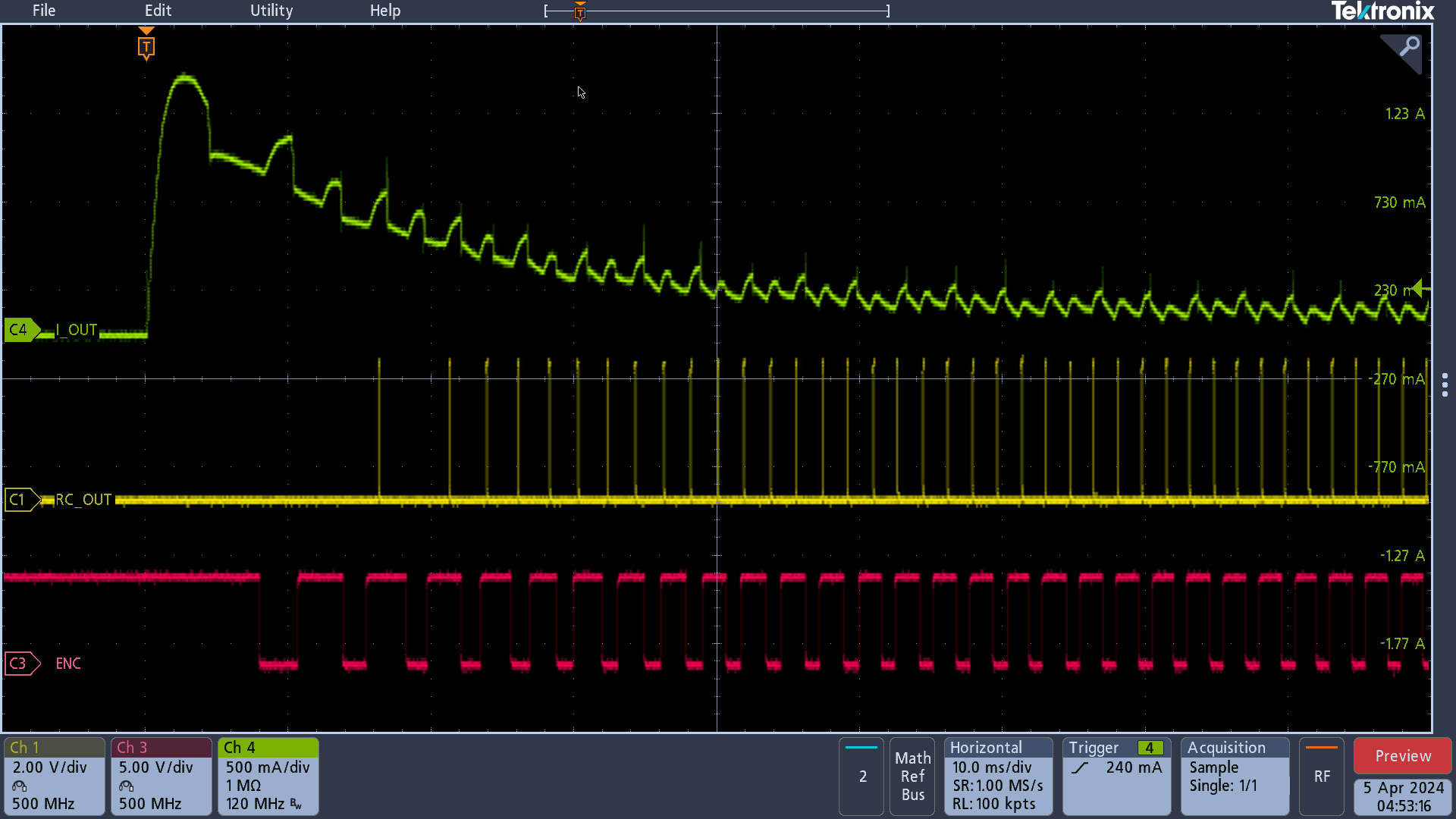

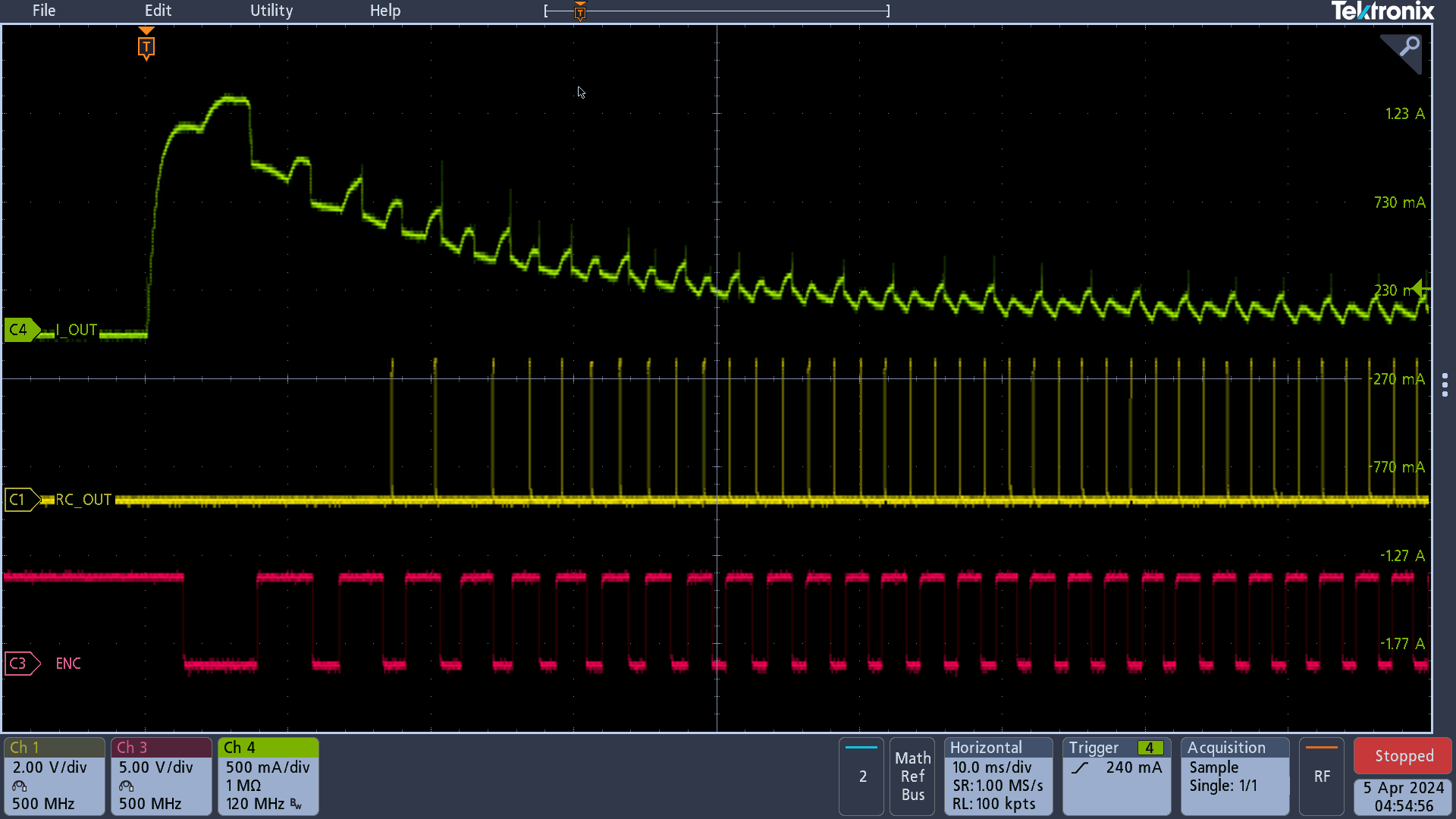

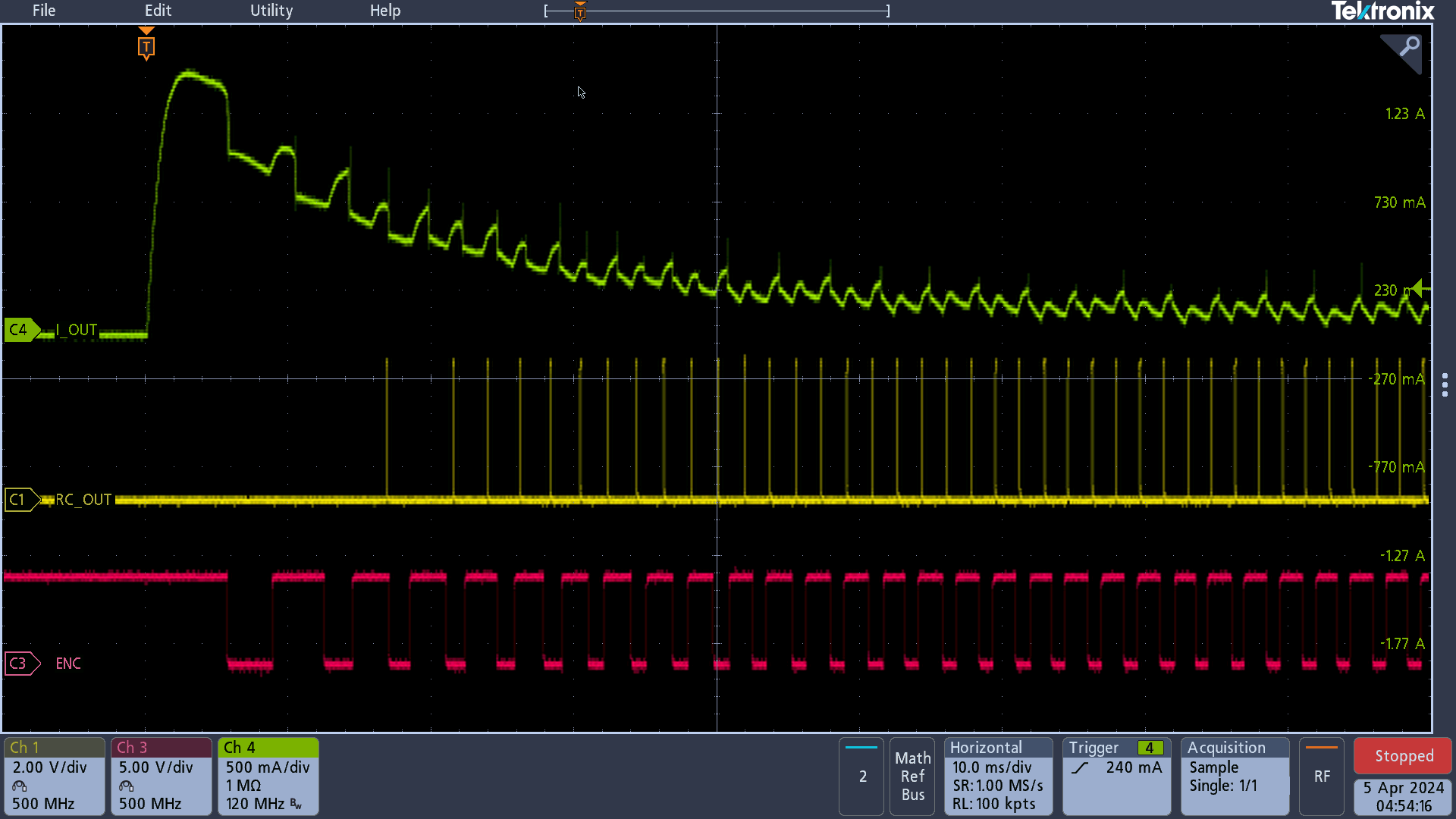

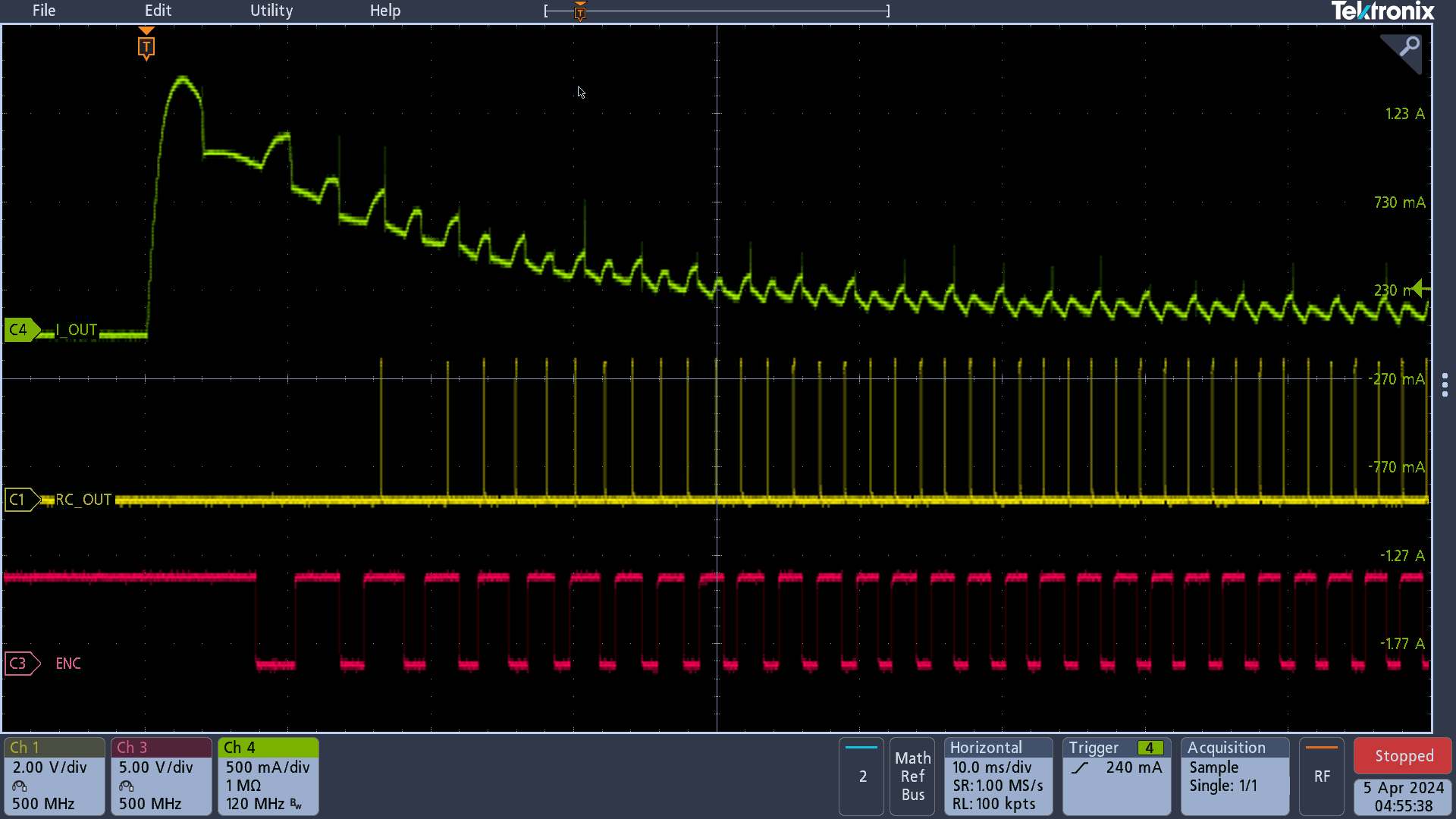

- Under same operating conditions and settings, the device consistently misses the same number of ripples each time. From Figure 4-6, Figure 4-7, Figure 4-8, and Figure 4-9, shows that the device misses 4 ripples during each start up. This can easily be accounted for simply by subtracting the missed ripples from the target ripple count. Programming the control unit to offset for four ripples enables position tracking with better accuracy.

Figure 4-6 Inrush 1

Figure 4-6 Inrush 1 Figure 4-8 Inrush 3

Figure 4-8 Inrush 3 Figure 4-7 Inrush 2

Figure 4-7 Inrush 2 Figure 4-9 Inrush 4

Figure 4-9 Inrush 4