SLVAFO8A April 2024 – May 2024 DRV8214 , DRV8234

- 1

- Abstract

- Trademarks

- 1Introduction: Need for Sensorless Designs

- 2Ripple Counting − Concept

- 3Case Study: Robotic Wheel Drive

- 4Challenges and Workarounds

- 5Summary

- 6References

- 7Revision History

3.3.2 Soft Start

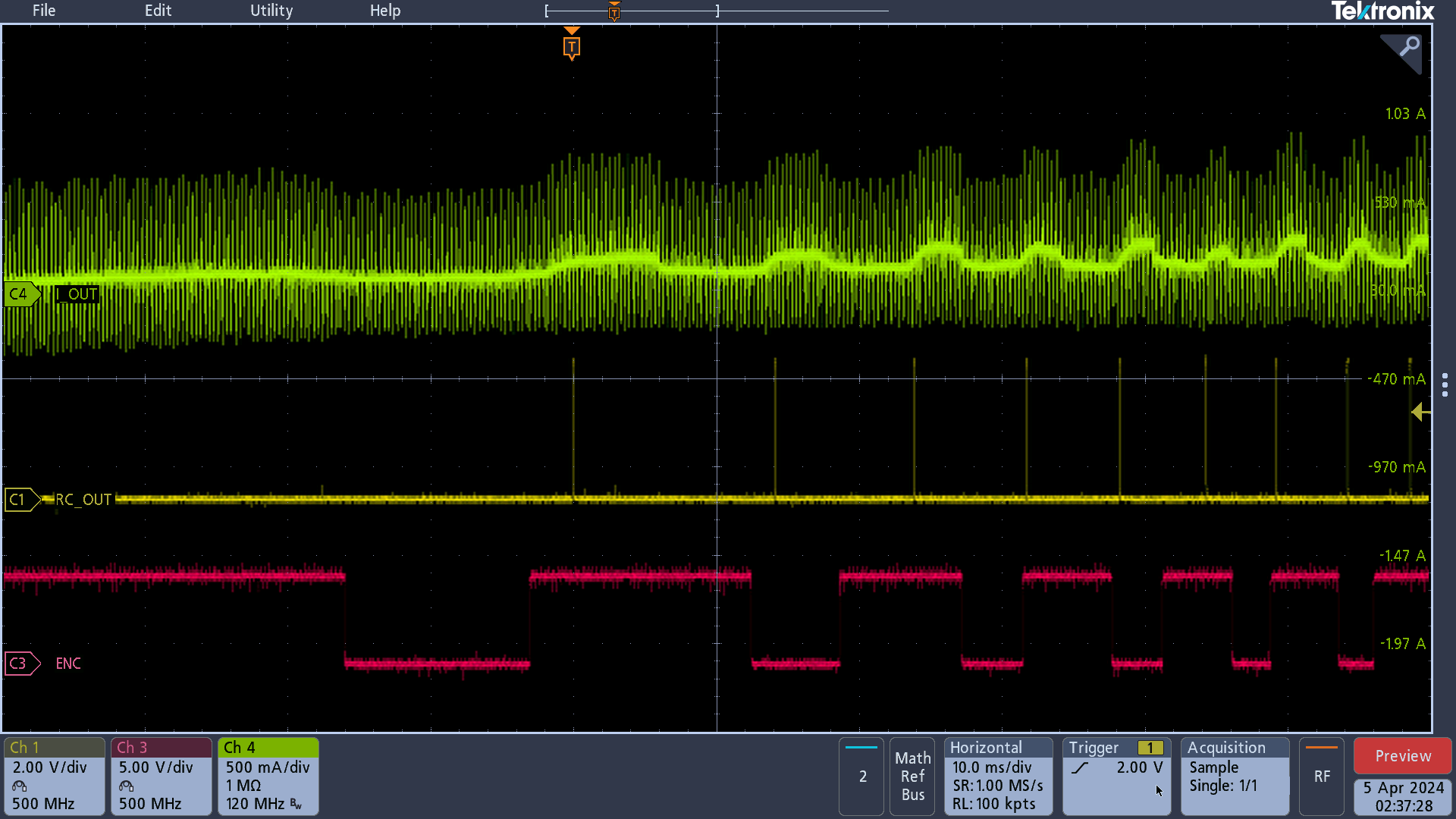

To protect against high inrush current transients as observed in Section 3.3.1, DRV8214 and DRV8234 have a soft-start feature that allows current to ramp-up to a preset value during the speed and voltage regulation modes. Figure 3-7 demonstrates the performance during soft start.

Figure 3-7 Performance During Soft

Start

Figure 3-7 Performance During Soft

Start Figure 3-8 Soft Start -

Zoomed

Figure 3-8 Soft Start -

ZoomedFrom Figure 3-7, we can see that all ripples are accurately tracked during soft start. This is validated by the accuracy calculation shown in Table 3-8. Counting is stopped when the motor completes 8 revolutions since the motor current value reaches steady state.

Table 3-8 Accuracy During

Soft-Start

| Parameter | Soft-Start |

|---|---|

| Encoder Counts | 32 |

| RC_OUT Counts | 48 |

| Accuracy | 100% |