SNOA954D November 2019 – June 2021 LDC0851 , LDC1001 , LDC1001-Q1 , LDC1041 , LDC1051 , LDC1101 , LDC1312 , LDC1312-Q1 , LDC1314 , LDC1314-Q1 , LDC1612 , LDC1612-Q1 , LDC1614 , LDC1614-Q1 , LDC2112 , LDC2114 , LDC3114 , LDC3114-Q1

1 LDC Applications

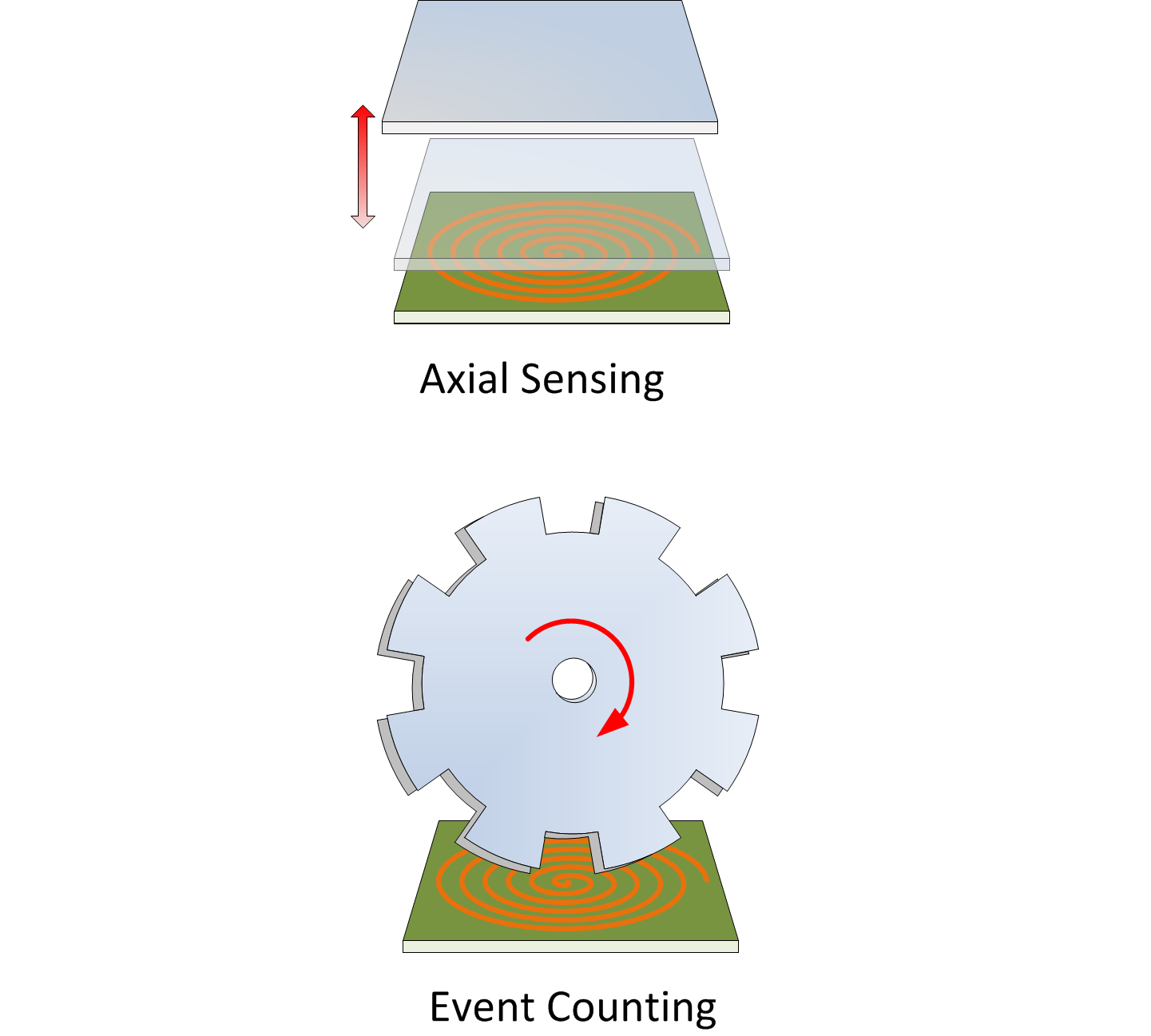

Inductive sensing provides contact-less sensing of conductive objects using only an AC magnetic field. This approach has many compelling features, including low cost, high reliability, low power consumption, and robust operation even in challenging environments experiencing high temperatures or in the presence of moisture, dirt, or oil. In addition, TI’s LDC devices do not require permanent magnets, and are not affected by permanent magnets. LDC technology can measure a wide range of target movement configurations, as shown in Figure 1-1.

Figure 1-1 LDC Sensing Configurations

Figure 1-1 LDC Sensing Configurations