TIDT293 October 2022

3.7 Slew Rate Adjust

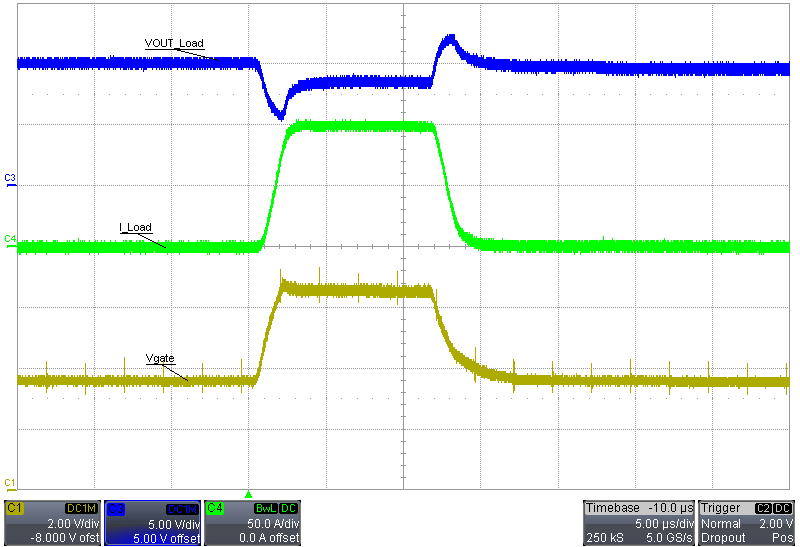

The slew rate adjustment is made by turning the potentiometers R12 and R58. Jumpers J4 and J5 can be installed to set the range of slew rate adjustments. The measured slew rate can be as high as 100 A/µs. The results in the following waveform use a PSMN008-75B MOSFET in the 125-A, 50-V variant.

Figure 3-13 10-V Output, 1-A to 100-A Load Transient, 1 µs Rise Time, Max Slew Rate

Figure 3-13 10-V Output, 1-A to 100-A Load Transient, 1 µs Rise Time, Max Slew Rate