SLAA910B August 2019 – January 2022 PGA460

TI Tech Note

Introduction

For robotic lawn mowers to be fully autonomous, they must be equipped with sensors that can detect the surrounding environment to bypass human operation.

Foreign objects on lawns must be avoided, as collisions could cause expensive malfunctions. Sensing technology must be able to perform reliably outdoors and be able to detect thin objects such as chair legs. Contactless ultrasonic sensing can be considered for obstacle detection, as it can perform efficiently while being exposed to harsh environmental conditions.

Current robotic lawn mowers require a perimeter wire around the desired area of operation, which can be costly, to maintain a directed path. Without a system in place to monitor where the robot is on the lawn, a robot can potentially go into unwanted areas and cause extensive damage. Ultrasonic sensing can detect the type of terrain the robot is on, therefore allowing the robot to efficiently traverse through grass without the need of external mechanisms.

Ultrasonic Theory of Operation

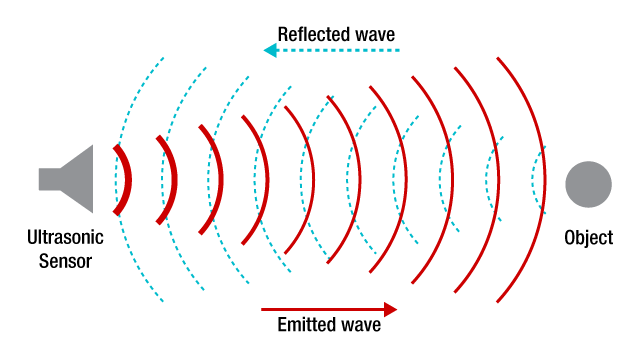

Ultrasonic sensors use high-frequency sound waves that are above the upper limit of human hearing and can transverse through different mediums (which affect the speed of sound) to determine where an object is relative to the point of the transducer. The time it takes for the emitted sound wave to reflect back to the transducer is multiplied by the speed of sound and divided by two for an accurate distance measurement.

It is important to note that, as frequency increases, the resolution, directivity, and attenuation increase, but the measurable distance decreases. Figure 1-1 shows how an ultrasonic sensor uses sound waves to operate.

Figure 1-1 Ultrasonic Sensor Theory of Operation

Figure 1-1 Ultrasonic Sensor Theory of OperationThe PGA460, which is a fully-integrated ultrasonic transducer driver and conditioner, was used to gather accurate results for these experiments. It is compatible with ultrasonic transducers that operate at a center frequency between 30–80 kHz and 180–480 kHz.

Proper Insulation and Mounting

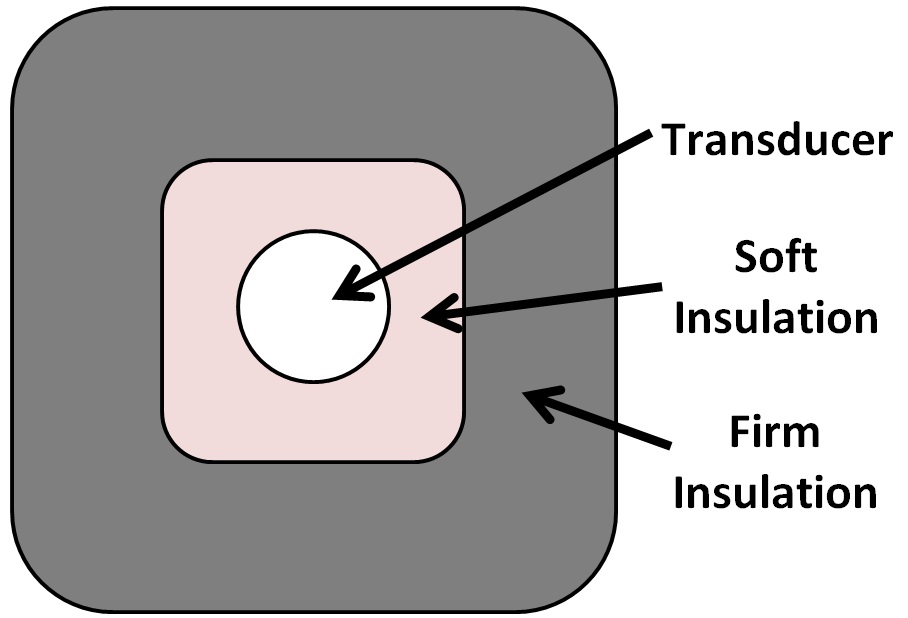

Robotic lawn mower applications require that transducers are exposed to harsh environments, therefore a closed-top transducer is recommended. It is important to surround the transducer in a soft material to allow vibration, followed by a firm material to keep the transducer in place and negate any exterior vibrations from affecting the device.

Figure 1-2 shows how a transducer must be insulated to optimize the signal observed on the BOOSTXL-PGA460 Graphical User Interface (GUI).

Figure 1-2 Proper Insulation

Figure 1-2 Proper InsulationIf the transducer is not properly mounted, the chances of false positives increase, which decreases the reliability of the system.

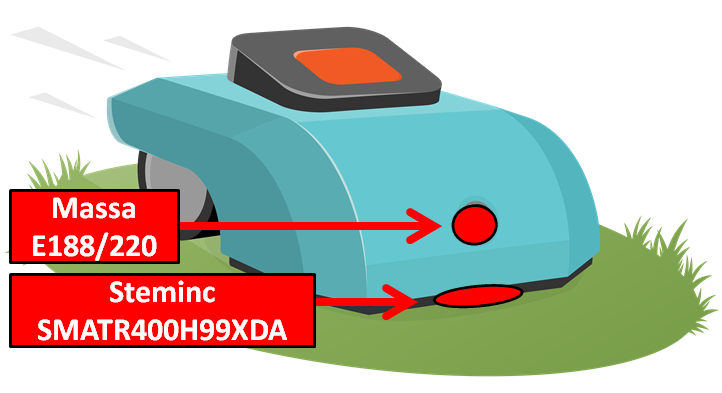

For obstacle detection, TI recommends to mount the transducer on the front of the lawn mower, facing outwards and slightly above the ground, to avoid reflections from the ground that could produce false positives. For terrain-type detection, TI recommends to mount the transducer underneath the lawn mower with the transducer pointing down. Figure 1-3 shows the recommended transducer mountings for obstacle and terrain-type detection on a robotic lawn mower.

Figure 1-3 Transducer Mounting on Lawn Mower

Figure 1-3 Transducer Mounting on Lawn MowerObstacle Detection

An object that comes within 15 cm of the mower should be recognized as a threat, and the system should instruct the robotic lawn mower to change directions and find an unblocked path. For obstacle detection, the 220-kHz Massa E188/220 closed-top transducer is recommended because the device is highly reliable within the 20-cm range.

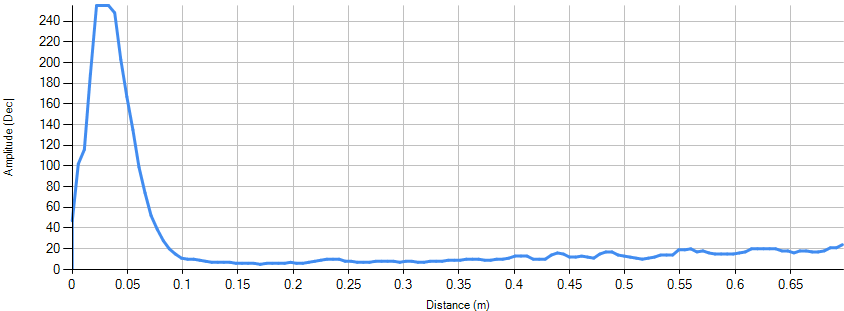

Figure 1-4 shows the echo response of the transducer when an obstacle is not obstructing the device. The initial peak observed is the ring time produced by monostatic transducers. Ring time can be shortened either by external hardware configuration or by implementing a bi-static topology. Refer to the PGA460 Ultrasonic Module Hardware and Software Optimization for more information.

Figure 1-4 Open Field Echo Response

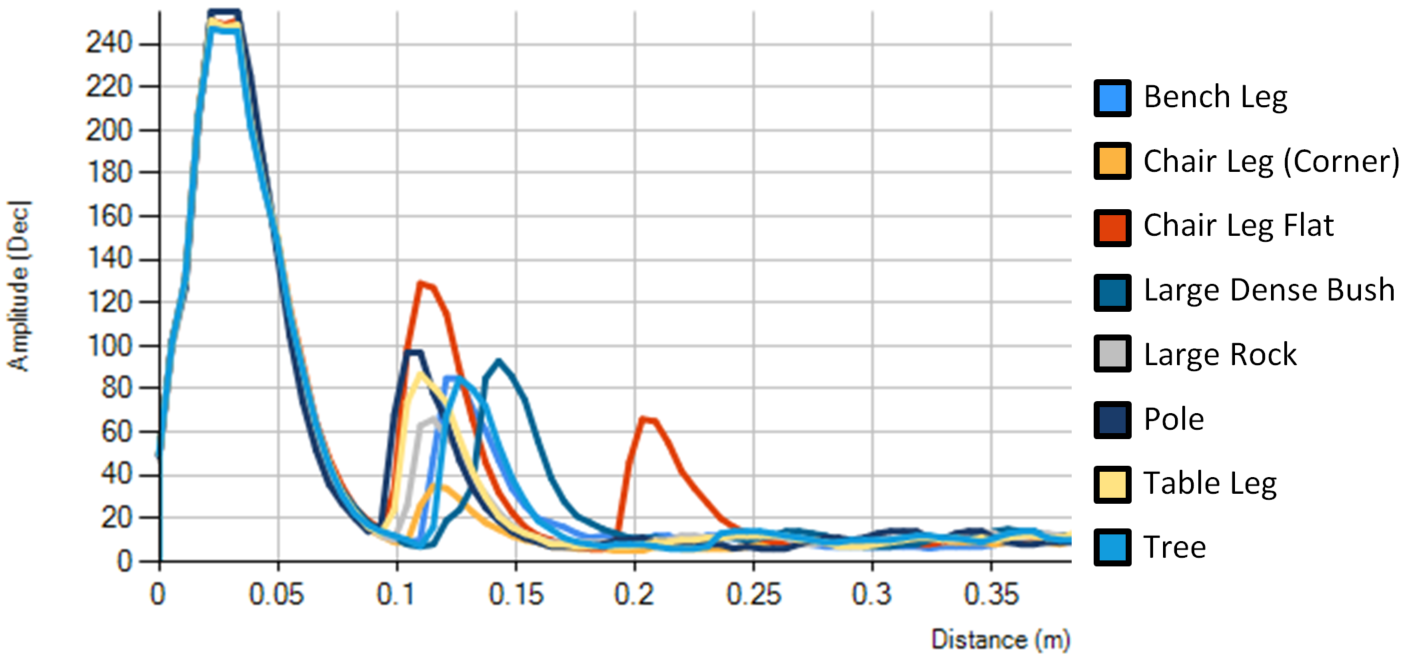

Figure 1-4 Open Field Echo ResponseFigure 1-5 shows the detection of objects commonly found on lawns using the Massa E188/220. When an object is within the 15-cm threshold, the transducer receives an echo response. Unlike other sensing technologies, ultrasonic sensing is able to reliably detect targets in outdoor conditions, including thin objects like chair legs and poles.

Figure 1-5 Obstacle Detection Under 15 cm

Figure 1-5 Obstacle Detection Under 15 cmTerrain-Type Detection

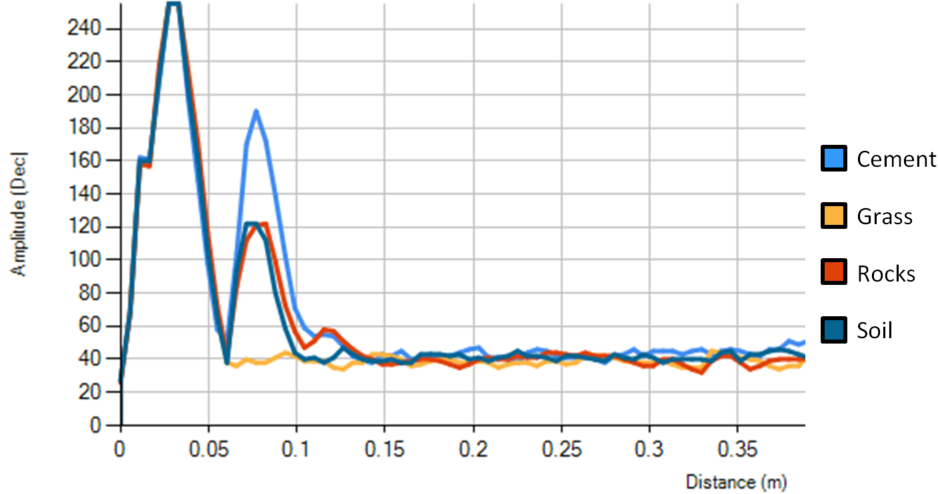

Figure 1-6 shows how the 400-kHz Steminc SMATR400H99XDA closed-top transducer performed in terrain-type detection when the sensor was 5 cm above the ground. A higher-frequency transducer is used for this application to reduce ring time, which allows for a shorter minimum detection range. Cement had a large echo response because of the hardness of the surface, whereas grass had close to no echo response due to the diffuse reflection from the random pattern surface type.

Figure 1-6 Terrain-Type Detection

Figure 1-6 Terrain-Type DetectionDevice Recommendations

Because the robotic lawn mower is exposed to harsh environments, including water and dirt, a closed-top transducer must be implemented. For reliable short range detection, the transducer must be able to emit high-frequency sound waves.

For terrain-type detection, the minimum measurable distance was 5 cm in these experiments. Therefore, a 400-kHz transducer was used to accommodate for low range detection. Because obstacle detection requires low to mid-range detection, a 220-kHz transducer was used.

The PGA460 device is a highly-integrated system with an on-chip ultrasonic transducer driver and signal conditioner with an advanced DSP core. Table 1-1 includes a list of collateral resources to help ensure proper usage of the BOOSTXL-PGA460, along with different transducers that are available. For more information, go to ti.com/ultrasonic.

| COLLATERAL | DESCRIPTION |

|---|---|

| Application Note | PGA460 Ultrasonic Module Hardware and Software Optimization |

| Quick Start Guide | PGA460-Q1 EVM Quick Start Guide |

| Excel Spreadsheet | PGA460: Air-Coupled Ultrasonic Transducers & Transformers Listing |

Application Note | |

Video Series |

Device | Characteristics | Considerations |

| Transformer drive ultrasonic sensor with integrated logarithmic amplifier | This device is intended for use for transformer drive to step up transducer voltage for increased burst sound pressure level. TUSS4440 supports a transducer frequency range of 40 kHz to 400 kHz | |

| Direct drive ultrasonic sensor with integrated logarithmic amplifier | This device is capable of directly driving the ultrasonic transducer or may be configured as pre-driver for external FETs. The TUSS4470 supports a wide range of transducer frequencies from 40kHz to 1MHz | |

| Ultrasonic sensing analog front end for level sensing with configurable low power modes | If paired with MSP430 or C2000 MCU can provide a complete ultrasonic sensing solution. TDC1000 supports a transducer frequency range from 31.25 kHz to 4 MHz. |