SLVSF16B January 2021 – April 2022 DRV8316

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Description

- 8.3.1 Output Stage

- 8.3.2 Control Modes

- 8.3.3 Device Interface Modes

- 8.3.4 Step-Down Mixed-Mode Buck Regulator

- 8.3.5 AVDD Linear Voltage Regulator

- 8.3.6 Charge Pump

- 8.3.7 Slew Rate Control

- 8.3.8 Cross Conduction (Dead Time)

- 8.3.9 Propagation Delay

- 8.3.10 Pin Diagrams

- 8.3.11 Current Sense Amplifiers

- 8.3.12 Active Demagnetization

- 8.3.13 Cycle-by-Cycle Current Limit

- 8.3.14

Protections

- 8.3.14.1 VM Supply Undervoltage Lockout (NPOR)

- 8.3.14.2 AVDD Undervoltage Lockout (AVDD_UV)

- 8.3.14.3 BUCK Undervoltage Lockout (BUCK_UV)

- 8.3.14.4 VCP Charge Pump Undervoltage Lockout (CPUV)

- 8.3.14.5 Overvoltage Protections (OV)

- 8.3.14.6 Overcurrent Protection (OCP)

- 8.3.14.7 Buck Overcurrent Protection

- 8.3.14.8 Thermal Warning (OTW)

- 8.3.14.9 Thermal Shutdown (OTS)

- 8.4 Device Functional Modes

- 8.5 SPI Communication

- 8.6 Register Map

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

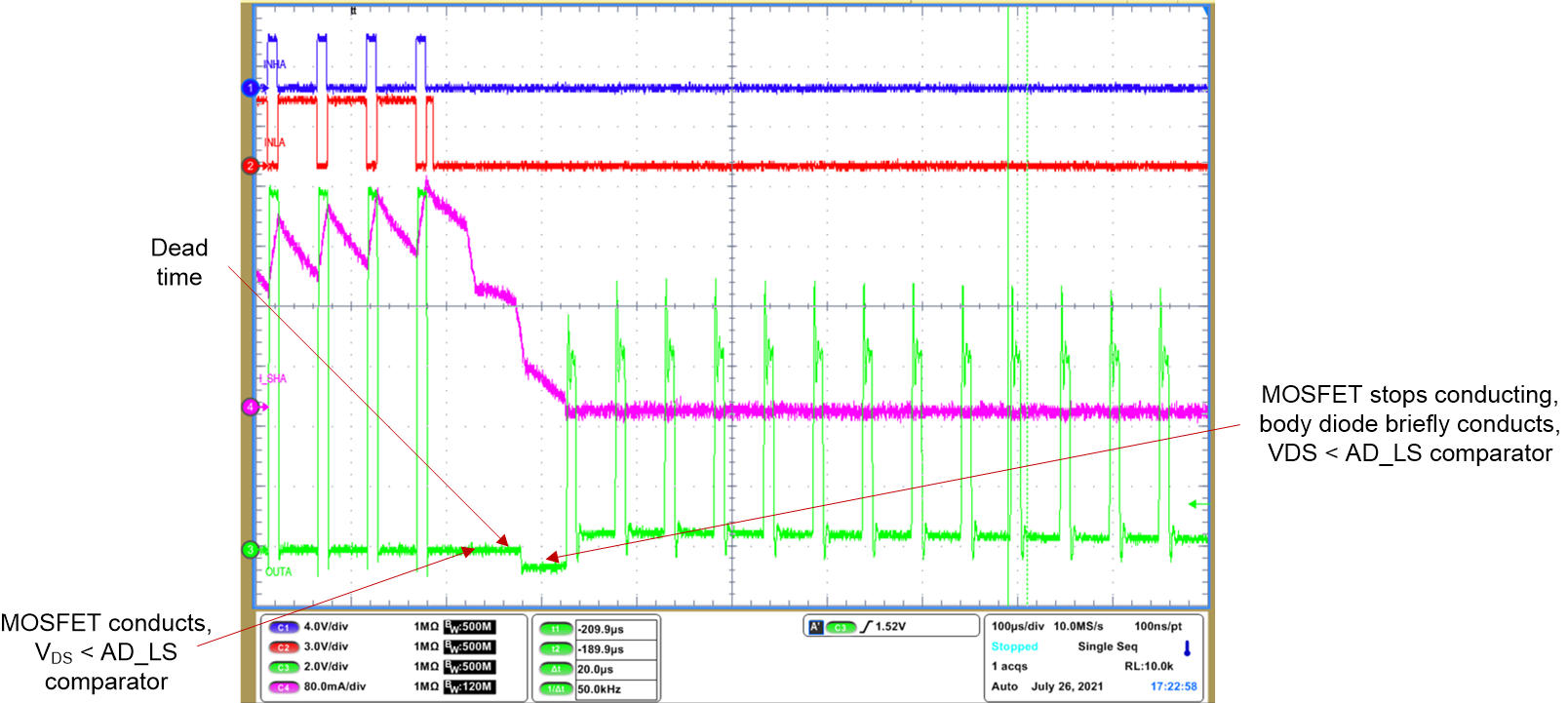

9.2.1.1.2 Using Active Demagnetization

Active demagnetization reduces power losses in the device by turning on the MOSFETs automatically when the body diode starts conducting to reduce diode conduction losses. It is used in trapezoidal commutation when switching commutation states (turning a high-side MOSFET off and another high-side MOSFET on while keeping a low-side MOSFET on). Active demagnetization is enabled when EN_ASR and EN_AAR bits are set in the SPI variant or OCP/SR pin is set to Mode 3 or Mode 4 in the H/W variant.

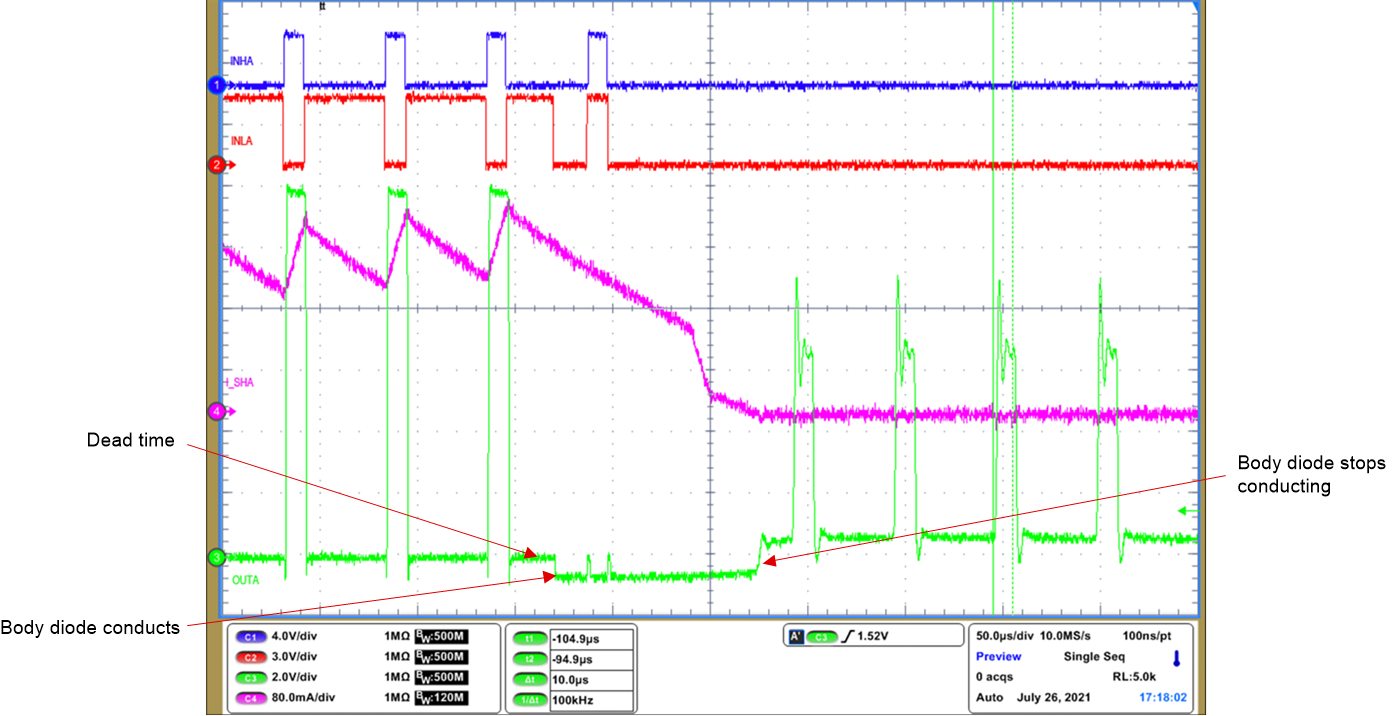

When switching commutation states with active demagnetization disabled, dead time is inserted and the low-side MOSFET’s body diode conducts while turning another high-side MOSFET on to continue sourcing current through the motor. This conduction period causes higher power losses due to the forward-bias voltage of the diode and slower dissipation of current. Figure 9-2 shows the body diode conducting when switching commutation states. Figure 9-2 Active demagnetization

disabled in DRV8316

Figure 9-2 Active demagnetization

disabled in DRV8316 Figure 9-3 Active demagnetization enabled

in DRV8316

Figure 9-3 Active demagnetization enabled

in DRV8316