SPRUHJ0C April 2013 – October 2021 TMS320F28068M , TMS320F28069-Q1 , TMS320F28069M , TMS320F28069M-Q1

Scenario 2: InstaSPIN-MOTION Speed Control with a Mechanical Sensor

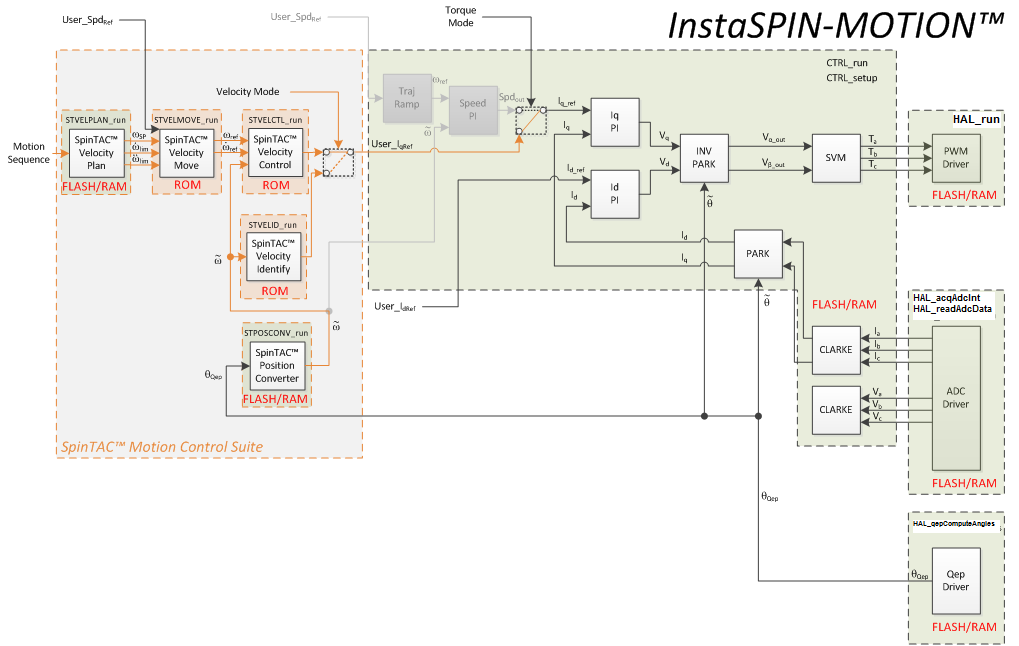

While sensorless solutions are appealing and cost effective for many applications, there are some applications that require the rigor and accuracy of a mechanical sensor. For these applications (see Figure 4-3), the quadrature encoder provides position information, which is then converted to speed feedback via the SpinTAC Position Convert. SpinTAC Velocity Control receives the speed feedback and generates the torque reference signal via IqRef. The SpinTAC Motion Control Suite provides the motion sequence state machine, generates the reference trajectory, and controls the system speed.

Figure 3-3 InstaSPIN-MOTION Speed Control with a Mechanical Sensor

Figure 3-3 InstaSPIN-MOTION Speed Control with a Mechanical Sensor