SNVAA45 July 2022 LM5160 , TPS272C45 , TPS274160 , TPS27S100 , TPS27SA08

1 Application Brief

Introduction

Driving inductive loads, for example, solenoids, relays or valves, is a common task for digital output modules in the field of Factory Automation. Usually the load is described as an inductance in series with a resistor and can be steered by a FET. After charging the inductance in the ON-state, the inductance has to discharge its stored energy during the OFF-state. When switched off, inductive loads generate a transient negative voltage of hundreds of volts due to the stored magnetic energy in the inductance. This transient voltage can cause severe damage to the drive circuit. To prevent any potential damage, during switch-off the stored magnetic energy must be dissipated by clamping the voltage across the inductive load.

De-energizing an inductive load is commonly implemented in one of three configurations: clamp across the switch, clamp across the load, or a freewheeling diode across the load. For the concept introduced in the following, the first one is chosen since it is integrated in TI's smart high-side switches (HSS). The first two approaches lead to high heat generation by dissipating the discharge energy quickly in the clamping diode, while the freewheeling diode comes with long demagnetization times due to the low voltage drop. These characteristics are limitations on the maximum allowable discharge energy and switching frequency. The switching frequency is also constrained by the time needed to cool down to avoid thermal shutdown of the involved IC. In-depth details on working with inductive loads is found in the How to Drive Inductive, Capacitive, and Lighting Loads (with smart high-side switches) application note.

Designers need to ensure that the inductance can be both completely charged and discharged to ensure the correct functionality of the application and avoid failure by choosing one of the previously-outlined de-energizing methods. In the case of discharging, the required time is inversely proportional to the clamping voltage of the diode. Thus, the selected clamping voltage must be high enough to limit the discharge time according to system requirements. The time needed for charging depends on the inductance of the load and the current through it. With this the frequency at which the inductive load can be driven is defined.

With the increasing importance of energy saving for sustainability, the demand is also rising for systems with low power loss in industrial applications. The proposed concept helps achieve this goal by recuperating energy from the inductive discharge back into the power supply of the system.

Improved Inductive Discharge Concept

To remedy the previously-outlined limitations, this document describes a new method to raise the admissible switching frequency of inductive loads through decreasing heat generation. Additionally, the discharge energy is recuperated back into the power supply of the PLC system reducing stress on it. The scheme can be implemented without the need to change existing digital output modules.

The Improved Inductive Discharge concept revolves around the LM5160, a 65-V, 2-A synchronous buck converter used in an inverting buck-boost configuration. The LM5160 suits well for this application through its fast transient response and 2-A current limit needed to handle the rapid, high-energy discharge pulses well. The most important feature is the ability to sink high reverse currents by disabling diode emulation, which is taken advantage of for the proposed scheme. During discharge the inductance serves as power source for the LM5160 transferring the energy in reverse manner to the PLC power supply, which is typically at 24 V. To store the discharge energy and release it later on, a bulk capacitor is attached to the LM5160. This form of recuperation reduces stress on the power supply. In the concept introduced in this document, TI's dual-channel smart high-side switch TPS272C45A is used to drive the inductive load by switching the 24-V DC supply on and off to the inductor. The schematic block diagram in Figure 1-1 shows a high-level overview of the involved devices for the Improved Inductive Discharge concept, which could be implemented in a standalone companion module without changing the original digital output module.

Some important aspects must be considered to ensure the LM5160 works in the intended way with respect to the simplified circuitry drawn in Figure 1-1:

- PLC systems work with DC voltages ranging from 18 V to 30 V. This variation introduces additional complexity; thus, first focus only on the typical supply voltage of Vsupply = 24 V for the scope of this document for an easier explanation.

- The input voltage limit, Vin,max = 65 V, of the device must not be violated at any time. Leaving some headroom for optimization, the GND potential (AGND, PGND, PAD pins) of the LM5160 is set to LM5160in = –14 V by the voltage divider at the feedback pin. Through this the discharge voltage will be "clamped" by the LM5160 at –14 V.

- In case the discharge voltage would rise above the clamping voltage of the TPS272C45A internal diode of VDS,Clamp,min = 49 V, the discharge energy is dissipated in the diode, which needs to be avoided to benefit from the use of LM5160.

- LM5160 has a load current limit of Imax = 2 A. This is especially important to keep in mind when switching with multiple channels at the same time since one LM5160 device could be used for multiple digital output channels. Note that the peak currents will be higher in an inverting buck boost configuration than in a standard buck configuration. This fact also needs to be considered when selecting the current rating of the inductor of the LM5160. See the Working With Inverting Buck-Boost Converters application note for more detailed information.

- Due to the parallel capacitors at the VIN pin of the LM5160 being referenced to LM5160in instead of GND, they are subject to a higher voltage (Vsupply + |LM5160in|) and therefore need to be selected with an appropriate voltage rating.

- The bulk capacitance must be dimensioned in a way that the additional energy fed in from an inductive load discharge will not result in an overly high voltage increase of the 24-V rail. Such a raised voltage Vmax can be estimated by comparing the energy stored in the inductive load with the change in capacitor energy. For a fully-charged inductive load find EL = 0.5 × L × I2, which corresponds to the energy surplus that needs to be dissipated during every discharge pulse. With Cin as the cumulative capacitance of all input capacitors at VIN of the LM5160 added to the bulk capacitance, the equation is written as follows: Equation 1.

With η describing the efficiency of LM5160 and other surrounding circuitry. Note, write 2 × EC, as the inductive load discharges into the bulk capacitor only during the ON time of the LM5160 high-side FET, following the detailed outlines in the next section.

Recuperating Inductive Discharge Energy

Studying the circuitry around LM5160 in the proposed concept depicted in Figure 1-1, observe five important points:

- During normal operation (HSS is OFF, no load connected) Vsupply = 24 V DC is applied to the VIN pin.

- VOUT is tied to ground, implying an inverting buck-boost configuration.

- The ground of the IC, that is, AGND, PGND, PAD, are exposed to LM5160in voltage, which is regulated to –14 V in steady-state operation according to the feedback resistor divider.

- Between VIN and board ground, a bulk capacitor is added to store the discharge energy.

- LM5160 works in continuous conduction mode (CCM) at all loads with diode emulation disabled. Thus, the inductor current can flow in either direction through the low-side FET. Bidirectional current flow through the high-side FET is innately allowed due to the design of the FET.

After start-up the LM5160in voltage rail is steadily at –14 V. This state remains during HSS ON-state because a Schottky diode prevents current flow from HSS output towards LM5160. In the ON-state the inductive load is charged for a certain amount of time, the HSS on-time. When switching off the HSS, the energy stored in the inductor has to be fully discharged during the HSS off-time. Following Faraday's Law, the inductor voltage needs to reverse its polarity to maintain a continuous current flow. Because of this negative voltage applied to the Schottky diode at LM5160in, the diode conducts towards LM5160. While discharging, the LM5160 allows the inductive load discharge current to flow reversely from SW to PGND during low-side FET ON-state. When switching the LM5160 high-side FET to ON, the device will route the reverse current from the discharge through SW to VIN, charging the bulk capacitor. With this behavior the LM5160 provides a current path for the inductive load to discharge its stored energy and by regulating to –14 V the clamping behavior at 24 V Vsupply is similar to a 38-V clamping diode. This discharge voltage limit already prevents reaching the 48-V clamping voltage of the HSS diode, so there is no current flowing through this diode when the design is operated as previously described. By adjusting the feedback resistor divider, one could also push the regulation voltage further into the negative, increasing the clamping voltage and therefore enabling faster discharging and, thus, higher switching frequencies.

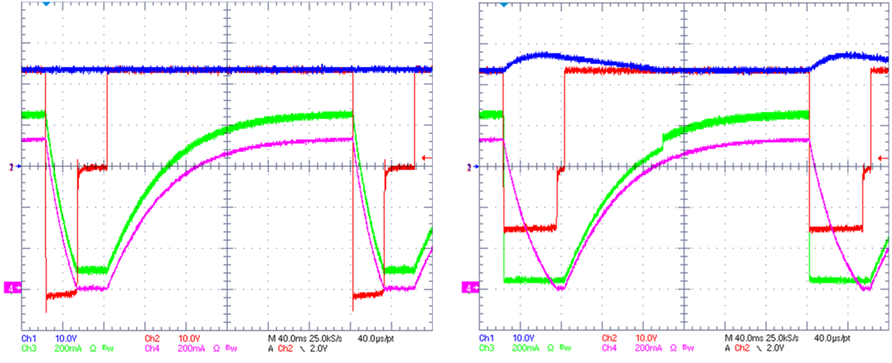

To demonstrate the advantages of the Improved Inductive Discharge scheme, Figure 1-2 shows a comparison between the Improved Inductive Discharge and the standard approach with discharging through the internal clamping diode of the TPS272C45A. The test conditions were: Vsupply = 24 V, Iload = 700 mA, and fsw = 3 Hz. Figure 1-2 shows the voltage at HSS VIN pin (blue), the voltage at inductive load (red), the current drawn from the power supply (green), and the current flowing into the load (magenta). Figure 1-1 also clarifies where each measurement has been taken. During the discharge of the inductive load (1.1 H was used for all tests), the bulk capacitor is charged up to Vmax = 28 V. Since the capacitor voltage is now above Vsupply it can discharge this voltage surplus to the system. Thereby it reduces stress on the PLC supply by providing current for the inductive discharge and it also supplies current at the start of the next charging phase in a continuous switching application. This is evident viewing the power supply load, which instantly drops to a lower level during discharge when the Improved Inductive Discharging is used.

Figure 1-2 Voltage and Current Curves of Standard and Improved Inductive Discharging

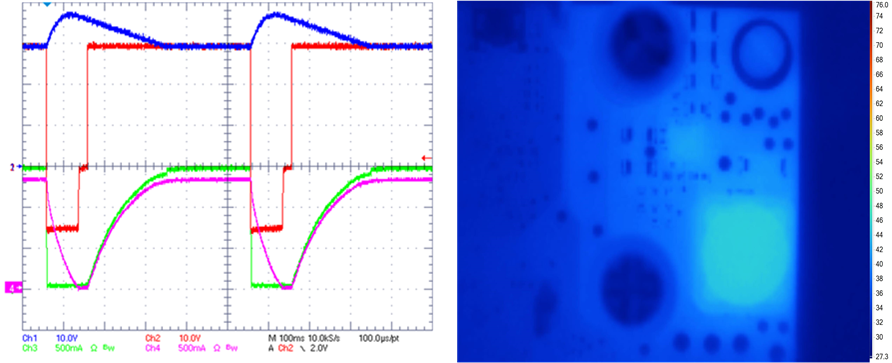

Figure 1-2 Voltage and Current Curves of Standard and Improved Inductive DischargingHowever, the most outstanding benefit of this approach is clearly the difference in heat generation during operation shown in Figure 1-3, depicting thermal shots of TPS272C45A during standard discharging (left) vs Improved Inductive Discharge (right) at Vsupply = 24 V, Iload = 700 mA, and fsw = 3 Hz. To demonstrate the effect of the LM5160, the temperature range on the figures is set to show values between the board temperature (27°C) and the maximum heat at the HSS with the above outlined settings (76°C). This temperature range is also used for other thermal shots in this document. The maximum admissible load and switching frequency of the standard approach are very limited by the high heat resulting from dissipation in the HSS diode, even though the high clamping voltage suggests higher frequencies would be achievable. Note that the maximum admissible inductive load decreases with heat according to the TPS272C45A data sheet. With the proposed Improved Inductive Discharge scheme, the HSS stays at a low temperature of approximately 30°C. Also, the LM5160 does not show significant heat development. This also means, that with the proposed concept, the switching frequency is only depending on the load inductance and current, and is not depending on potential thermal shutdown of the HSS. Whereas, the TPS272C45A would get damaged through the increased heat generation at a higher switching frequency.

Figure 1-3 Heat Generation at the High-Side Switch During Operation

Figure 1-3 Heat Generation at the High-Side Switch During OperationIn the previously-shown tests, the current was limited to 700 mA to ensure a safe operation of the HSS as higher loads would destroy the FET during discharge. To further demonstrate the capabilities of the proposed Improved Inductive Discharge scheme, another test was conducted with Vsupply = 30 V, Iload = 1.3 A, and fsw = 2 Hz. Figure 1-4 shows how the voltage at the HSS VIN pin (blue), the current drawn from the power supply (green), and the voltage and current at the inductive load (red and magenta, respectively) behave. Even though the test conditions are beyond the technical limits of the TPS272C45A, the Improved Inductive Discharge scheme shows a maximum of merely 45°C at the inductor of the LM5160 during operation as the hottest part in the system. The TPS272C45A HSS operates at about 33°C, slightly above the board temperature due to the high current applied to it. Thus, the presented scheme allows to safely drive inductive loads with more current than the standard approach can manage. Also note, that the frequency could still be increased safely by shortening the HSS ON-time as the load is fully charged for a longer period. However, the peak voltage at the capacitor is now Vmax = 37 V, which must be remembered. This peak voltage can be lowered by increasing the available capacitance, that is, selecting a higher capacitance bulk capacitor. For reference, in all investigations shown in this document a 1-mF capacitor was used.

Figure 1-4 Improved Inductive Discharge Scheme With High Load

Figure 1-4 Improved Inductive Discharge Scheme With High LoadConclusion

In conclusion, the Improved Inductive Discharge scheme enables fast and save discharging of inductive loads, which can be implemented in a standalone companion module as add-on to existing digital output modules. It facilitates the use of larger inductances and higher currents while at the same time enabling higher switching frequencies by averting excess heat generation. Through recuperation of discharge energy, the scheme also reduces stress on the PLC power supply and contributes to the design of energy efficient systems.