SLAS468A June 2005 – August 2016 ADS7887 , ADS7888

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Companion Products

- 6 Device Comparison

- 7 Pin Configuration and Functions

- 8 Specifications

- 9 Detailed Description

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

- DCK|6

Orderable Information

12 Layout

12.1 Layout Guidelines

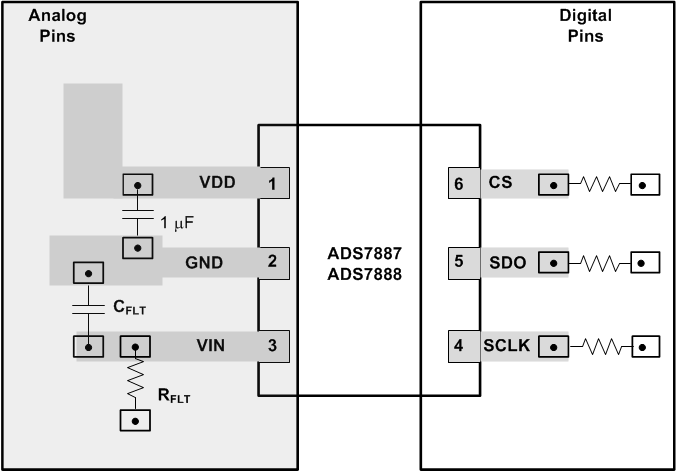

Figure 43 shows a board layout example for the ADS7887 and ADS7888. Some of the key considerations are:

- Use a ground plane underneath the device and partition the PCB into analog and digital sections.

- Avoid crossing digital lines with the analog signal path.

- The power sources to the device must be clean and well-bypassed. Use 1-µF ceramic bypass capacitors in close proximity to the supply pin (VDD).

- Avoid placing vias between the VDD and bypass capacitors.

- Connect ground pin to the ground plane using short, low-impedance path.

- The fly-wheel RC filters are placed close to the device.

Among ceramic surface-mount capacitors, COG (NPO) ceramic capacitors provide the best capacitance precision. The type of dielectric used in COG (NPO) ceramic capacitors provides the most stable electrical properties over voltage, frequency, and temperature changes.

12.2 Layout Example

Figure 43. ADS7887 and ADS7888 Example Layout

Figure 43. ADS7887 and ADS7888 Example Layout