SBOS764B December 2015 – December 2021 INA300-Q1

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3 Feature Description

- 7.4 Device Functional Modes

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DGS|10

Thermal pad, mechanical data (Package|Pins)

Orderable Information

7.4.3 Input Filtering

External system noise can have a significant effect in the ability of a comparator to accurately measure and detect whether input signals exceed the reference threshold levels, indicating an overrange condition. The device is susceptible to external noise, although the 50-µs and 100-µs delay settings are can mitigate the impact of noise based on the effective averaging achieved in these modes. The obvious effect that external noise can have on the operation of a comparator is to cause a false alert condition. If a comparator detects a large noise transient coupled into the signal, the device can interpret this transient as an overrange condition.

External filtering can help reduce the amount of noise that reaches the comparator inputs, and can reduce the likelihood of a false alert from occurring. The tradeoff to adding this noise filter is increased comparator response time, because of the input signal being filtered as well as the noise. Figure 7-9 shows the implementation of an input filter for the device.

Figure 7-9 Input Filter

Figure 7-9 Input FilterLimiting the amount of input resistance used in this filter is important because this resistance can have a significant effect on the input signal that reaches the device input pins resulting from the device input bias currents. A typical system implementation involves placing the current-sensing resistor near the device so the traces are short and the trace impedance is small. This layout helps reduce the ability of coupling additional noise into the measurement. Under these conditions, the characteristics of the input bias currents have minimal effect on device performance.

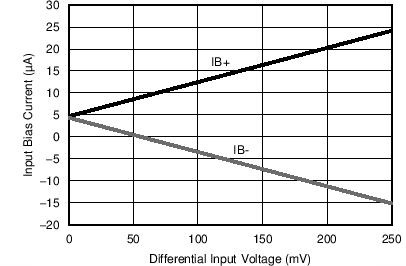

As shown in Figure 7-10, the input bias currents increase in opposite directions when the differential input voltage increases. This increase results from the design of the device, which allows common-mode input voltages to far exceed the device supply voltage range. With input filter resistors now placed in series with these unequal input bias currents, there are unequal voltage drops developed across the input resistors. The difference between the two drops appears as an added signal that (in this case) subtracts from the voltage developed across the current-sensing resistor, reducing the signal that reaches the device input terminals. Smaller value input resistors reduce this effect of signal attenuation to allow for a more accurate measurement.

Figure 7-10 Input Bias Current vs Differential Input Voltage

Figure 7-10 Input Bias Current vs Differential Input VoltageFor example, with a differential voltage of 10 mV developed across a current-sensing resistor and using 100-Ω resistors, the differential signal that reaches the device is 9.8 mV. A measurement error of 2% is created as a result of the external input filter resistors. Using 10-Ω input filter resistors instead of the 100-Ω resistors reduces this added error from 2% to 0.2%.