SNVS117E April 1998 – June 2019 LM2588

PRODUCTION DATA.

- 1 Features

- 2 Typical Applications

- 3 Description

- 4 Revision History

- 5 Pin Configurations

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Ratings

- 6.4 Electrical Characteristics: 3.3 V

- 6.5 Electrical Characteristics: 5 V

- 6.6 Electrical Characteristics: 12 V

- 6.7 Electrical Characteristics: Adjustable

- 6.8 Electrical Characteristics: All Output Voltage Versions

- 6.9 Typical Characteristics

- 7 Detailed Description

- 8 Application and Implementation

- 9 Layout

- 10Device and Documentation Support

- 11Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

- KTW|7

Orderable Information

9.3 Heat Sink/Thermal Considerations

In many cases, a heat sink is not required to keep the LM2588 junction temperature within the allowed operating temperature range. For each application, to determine whether or not a heat sink will be required, the following must be identified:

1) Maximum ambient temperature (in the application).

2) Maximum regulator power dissipation (in the application).

3) Maximum allowed junction temperature (125°C for the LM2588). For a safe, conservative design, a temperature approximately 15°C cooler than the maximum junction temperature should be selected (110°C).

4) LM2588 package thermal resistances θJA and θJC (given in the Electrical Characteristics).

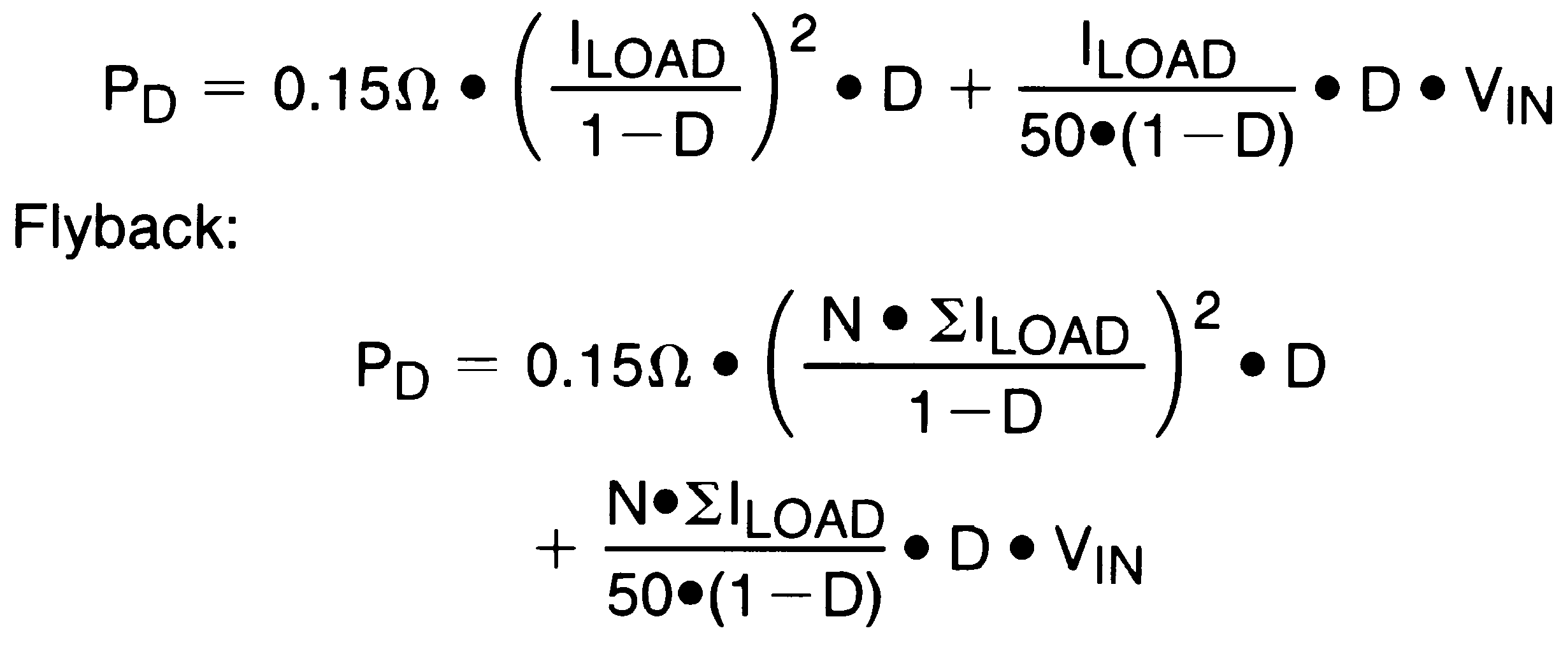

Total power dissipated (PD) by the LM2588 can be estimated as follows:

Boost:

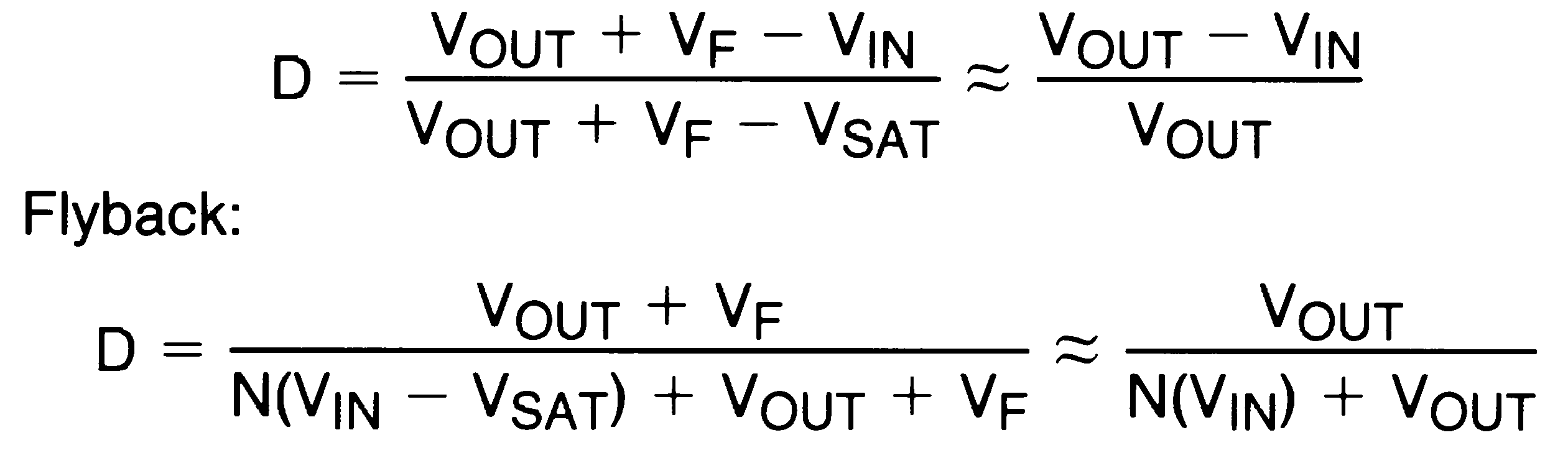

VIN is the minimum input voltage, VOUT is the output voltage, N is the transformer turns ratio, D is the duty cycle, and ILOAD is the maximum load current (and ∑ILOAD is the sum of the maximum load currents for multiple-output flyback regulators). The duty cycle is given by:

Boost:

where

- VF is the forward biased voltage of the diode and is typically 0.5V for Schottky diodes and 0.8V for fast recovery diodes

- VSAT is the switch saturation voltage and can be found in the Characteristic Curves.

When no heat sink is used, the junction temperature rise is:

Adding the junction temperature rise to the maximum ambient temperature gives the actual operating junction temperature:

If the operating junction temperature exceeds the maximum junction temperatue in item 3 above, then a heat sink is required. When using a heat sink, the junction temperature rise can be determined by the following:

Again, the operating junction temperature will be:

As before, if the maximum junction temperature is exceeded, a larger heat sink is required (one that has a lower thermal resistance).

Included in the Switchers Made Simple™ design software is a more precise (non-linear) thermal model that can be used to determine junction temperature with different input-output parameters or different component values. It can also calculate the heat sink thermal resistance required to maintain the regulator junction temperature below the maximum operating temperature.