SNVS690I January 2011 – August 2021 LMZ14201H

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1 Design Steps for the LMZ14201H Application

- 8.2.3 Application Curve

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- NDW|7

Thermal pad, mechanical data (Package|Pins)

Orderable Information

10.1.1 Power Module SMT Guidelines

The recommendations below are for a standard module surface mount assembly

- Land Pattern – Follow the PCB land pattern with either soldermask defined or non-soldermask defined pads

- Stencil Aperture

- For the exposed die attach pad (DAP), adjust the stencil for approximately 80% coverage of the PCB land pattern

- For all other I/O pads use a 1:1 ratio between the aperture and the land pattern recommendation

- Solder Paste – Use a standard SAC Alloy such as SAC 305, type 3 or higher

- Stencil Thickness – 0.125 mm to 0.15 mm

- Reflow - Refer to solder paste supplier recommendation and optimized per board size and density

- Refer to AN Design Summary LMZ1xxx and LMZ2xxx Power Modules Family (SNAA214) for Reflow information

- Maximum number of reflows allowed is one

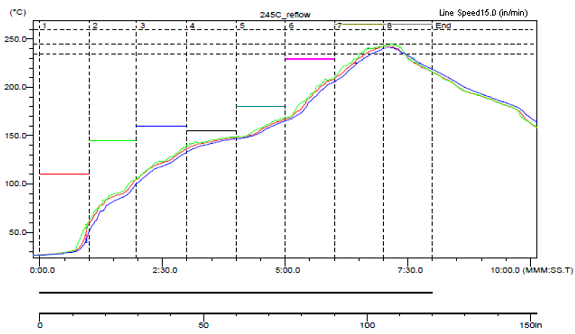

Figure 10-1 Sample Reflow Profile

Figure 10-1 Sample Reflow ProfileTable 10-1 Sample Reflow Profile Table

| PROBE | MAX TEMP (°C) | REACHED MAX TEMP | TIME ABOVE 235°C | REACHED 235°C | TIME ABOVE 245°C | REACHED 245°C | TIME ABOVE 260°C | REACHED 260°C |

|---|---|---|---|---|---|---|---|---|

| 1 | 242.5 | 6.58 | 0.49 | 6.39 | 0 | – | 0 | – |

| 2 | 242.5 | 7.1 | 0.55 | 6.31 | 0 | 7.1 | 0 | – |

| 3 | 241 | 7.09 | 0.42 | 6.44 | 0 | – | 0 | – |