SNAS647D February 2015 – March 2016 TDC7200

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Companion Device

- 6 Pin Configuration and Functions

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3 Feature Description

- 8.4 Device Functional Modes

- 8.5 Programming

- 8.6

Register Maps

- 8.6.1 Register Initialization

- 8.6.2 CONFIG1: Configuration Register 1 R/W (address = 00h) [reset = 0h]

- 8.6.3 CONFIG2: Configuration Register 2 R/W (address = 01h) [reset = 40h]

- 8.6.4 INT_STATUS: Interrupt Status Register (address = 02h) [reset = 00h]

- 8.6.5 INT_MASK: Interrupt Mask Register R/W (address = 03h) [reset = 07h]

- 8.6.6 COARSE_CNTR_OVF_H: Coarse Counter Overflow High Value Register (address = 04h) [reset = FFh]

- 8.6.7 COARSE_CNTR_OVF_L: Coarse Counter Overflow Low Value Register (address = 05h) [reset = FFh ]

- 8.6.8 CLOCK_CNTR_OVF_H: Clock Counter Overflow High Register (address = 06h) [reset = FFh]

- 8.6.9 CLOCK_CNTR_OVF_L: Clock Counter Overflow Low Register (address = 07h) [reset = FFh]

- 8.6.10 CLOCK_CNTR_STOP_MASK_H: CLOCK Counter STOP Mask High Value Register (address = 08h) [reset = 00h]

- 8.6.11 CLOCK_CNTR_STOP_MASK_L: CLOCK Counter STOP Mask Low Value Register (address = 09h) [reset = 00h]

- 8.6.12 TIME1: Time 1 Register (address: 10h) [reset = 00_0000h]

- 8.6.13 CLOCK_COUNT1: Clock Count Register (address: 11h) [reset = 00_0000h]

- 8.6.14 TIME2: Time 2 Register (address: 12h) [reset = 00_0000h]

- 8.6.15 CLOCK_COUNT2: Clock Count Register (address: 13h) [reset = 00_0000h]

- 8.6.16 TIME3: Time 3 Register (address: 14h) [reset = 00_0000h]

- 8.6.17 CLOCK_COUNT3: Clock Count Registers (address: 15h) [reset = 00_0000h]

- 8.6.18 TIME4: Time 4 Register (address: 16h) [reset = 00_0000h]

- 8.6.19 CLOCK_COUNT4: Clock Count Register (address: 17h) [reset = 00_0000h]

- 8.6.20 TIME5: Time 5 Register (address: 18h) [reset = 00_0000h]

- 8.6.21 CLOCK_COUNT5: Clock Count Register (address: 19h) [reset = 00_0000h]

- 8.6.22 TIME6: Time 6 Register (address: 1Ah) [reset = 00_0000h]

- 8.6.23 CALIBRATION1: Calibration 1 Register (address: 1Bh ) [reset = 00_0000h]

- 8.6.24 CALIBRATION2: Calibration 2 Register (address: 1Ch ) [reset = 00_0000h]

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- PW|14

Thermal pad, mechanical data (Package|Pins)

- PW|14

Orderable Information

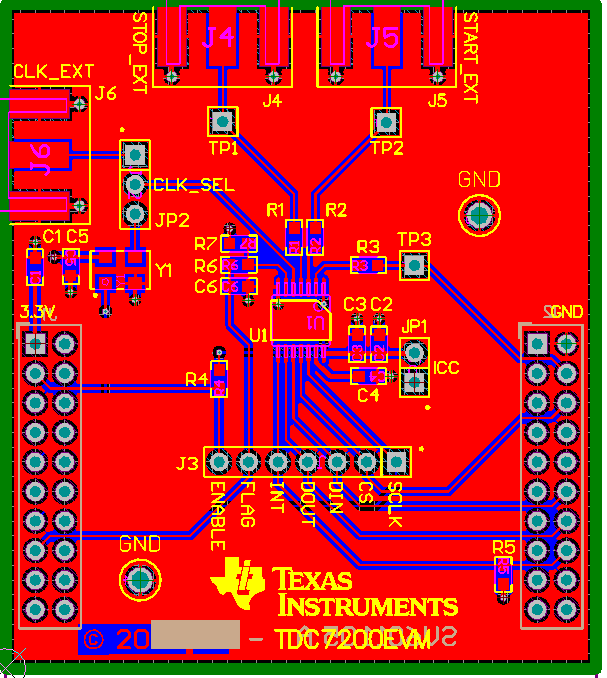

11 Layout

11.1 Layout Guidelines

- In a 4-layer board design, the recommended layer stack order from top to bottom is: signal, ground, power and signal.

- Bypass capacitors should be placed in close proximity to the VDD pin.

- The length of the START and STOP traces from the TDC7200 to the stopwatch/MCU should be matched to prevent uneven signal delays. Also, avoid unnecessary via-holes on these traces and keep the routing as short/direct as possible to minimize parasitic capacitance on the PCB.

- Route the SPI signal traces close together. Place a series resistor at the source of DOUT (close to the TDC7200) and series resistors at the sources of DIN, SCLK, and CSB (close to the master MCU).

11.2 Layout Example

Figure 50. TDC7200EVM Layout

Figure 50. TDC7200EVM Layout