SLVUCU7 November 2023 DRV8334

2.1 Hardware Connections Overview – DRV8334EVM + LAUNCHXL-F280049C

The following section describes the EVM hardware and connections to the external supply, hall sensors, PC via USB, and motor.

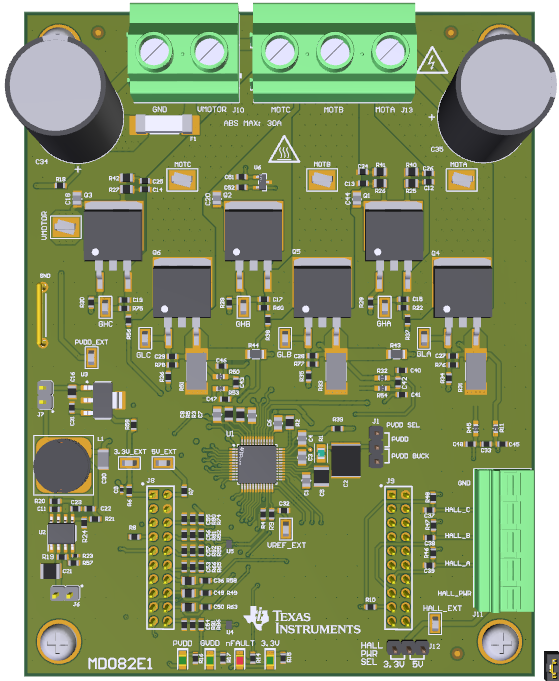

Figure 2-1 EVM Board Overview

Figure 2-1 EVM Board Overview Figure 2-2 DRV8334EVM Mating to LAUNCHXL-F280049C

Figure 2-2 DRV8334EVM Mating to LAUNCHXL-F280049CThe DRV8334EVM must plug into the LAUNCHXL-F280049C Launchpad headers closest to the USB port as shown above.

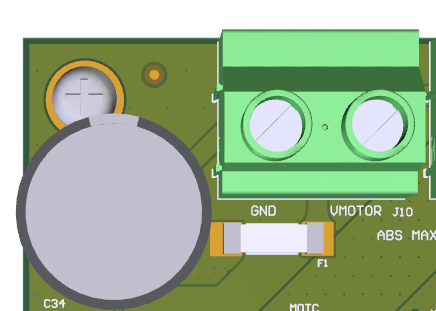

Figure 2-3 VMOTOR Input (J10)

Figure 2-3 VMOTOR Input (J10)To minimize the risk of potential shock hazard and personal injury, remove all power connections and interfaces to the DRV8334EVM when not in use.

The DRV8334EVM is designed for an input supply from 4.5 VDC to 60 VDC and up to 30-A continuous drive current (in-line fuse limited). The input connects to J10 with the noted polarity. VMOTOR test point connects to the same node but must not be used for high current input. VMOTOR input is fused with a 30 A fuse and the input connector is rated for 32 A.

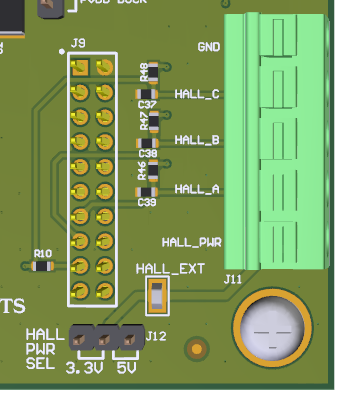

Figure 2-4 Hall Sensor Input and Power Connections (J11)

Figure 2-4 Hall Sensor Input and Power Connections (J11)Hall sensors are connected to J11 including hall power and GND. The 3.3 VDC supply to the Hall sensors is supplied from the 3.3 V LDO on the EVM. External hall power can be input through the HALL_EXT test point if a different supply or voltage level is desired. To use the included 3.3 V LDO to power the halls, connect J12 on the left side to pins 1:2 as shown. To use HALL_EXT, connect J12 on the right side to pins 2:3. To insert or remove wires/terminals on J11, use a flat blade screwdriver to push down the respective tab on top of the J11 connector.

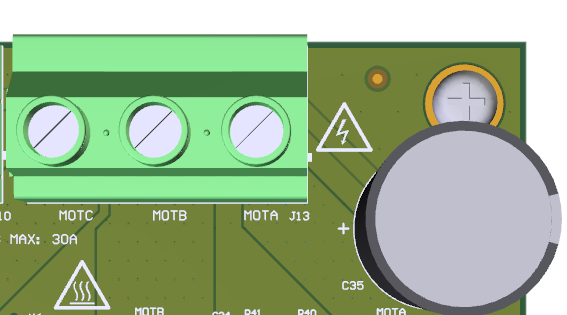

Figure 2-5 Motor Phase Connector (J13)

Figure 2-5 Motor Phase Connector (J13)Motor Phase connections must match the hall sensor connection sequence. For example, MOTA must match HALL_A, MOTB must match HALL_B, MOTC must match HALL_C. The phases must also be in sequential order; A, then B, then C.

If the motor phases do not match the hall sensors or the connections are made out of order, then the motor does not spin smoothly and current consumption increases.

The three phase inputs of the motor connect to MOTA/MOTB/MOTC through connector J13.