SSZT303 may 2020 DDC112 , DRV8873 , TMP117 , TPS54201

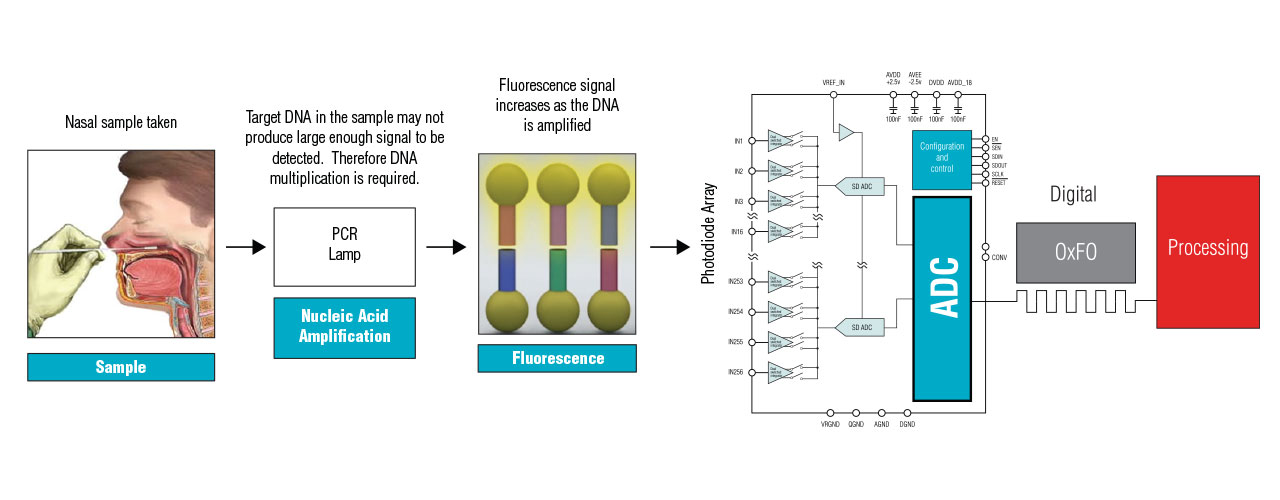

Growth in the point-of-care molecular diagnostics (PoC) market has been driven primarily by the high prevalence of infectious diseases; an increasing awareness and acceptance of personalized medicine; and advancements in molecular techniques, which have led to more accurate results and portability. PoC molecular diagnostics (Figure 1) enable physicians to improve the standard of care by combining quick diagnosis with a treatment decision at the first patient visit, rather than waiting days for test results. In this technical article, we will give a very brief description of this type of assay and detail some of the real-life components used in the main blocks of these instruments.

Figure 1 A generic representation on

how PoC molecular diagnostics analyzers work

Figure 1 A generic representation on

how PoC molecular diagnostics analyzers workAt a high level, the biological sample may not contain enough target DNA to be detected through optical fluorescence. Therefore, the analysis requires amplification (cloning/multiplication) of the DNA. The two main amplification techniques are Polymerase Chain Reaction (PCR) and Loop-Mediated Isothermal Amplification (LAMP).

| Prevention. Diagnosis. Treatment. | |

|

We are committed to helping you design and manufacture innovative medical systems for communities around the world. View our resources. |

The PCR and LAMP amplification techniques require certain heating and cooling elements. The PCR process requires a Thermo-Electric Cooler (TEC), which thermally cycles through three separate temperatures. These temperature changes include heating up the sample to 95°C, cooling it down to 50°C-56°C, and keeping it at a constant temperature of 72°C. Repeating this cycling process creates billions of copies of DNA. In the LAMP amplification process, a heating and cooling element keeps the sample at a constant temperature of 60°C-65°C. Avoiding thermal cycling helps expedite the reaction, but does require a more advanced set of primers.

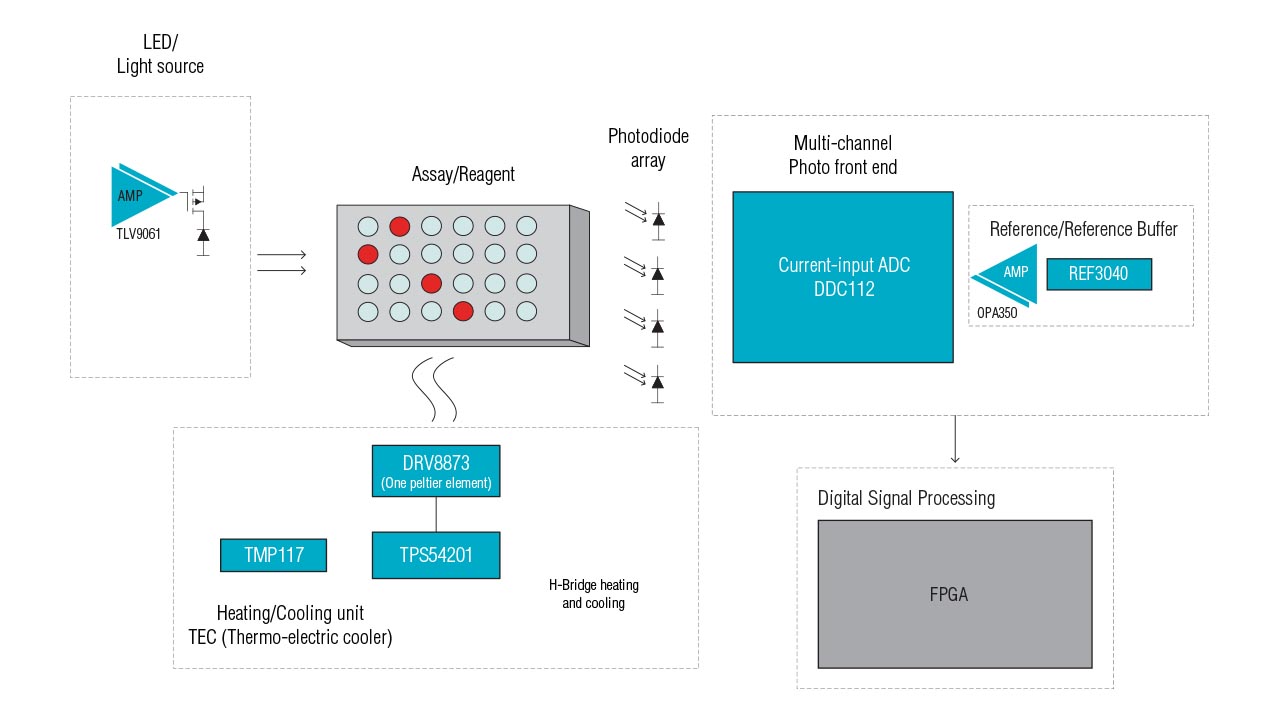

Figure 2 is a representation of a sensor front end/TEC unit for a PoC molecular diagnostics analyzer based on TI’s DDC112 current-input analog-to-digital converter (ADC), as well as TI current drives, precision amplifiers and temperature sensors.

Figure 2 A system block diagram of a

PoC molecular diagnostics analyzer sensor front end

Figure 2 A system block diagram of a

PoC molecular diagnostics analyzer sensor front endThe proper operation of a TEC unit requires a high level of temperature accuracy to monitor the heating and cooling required for the nucleic amplification process. The TMP117 digital sensor achieves ±0.1°C typical and ±0.2°C maximum accuracy over a -40°C to 100°C temperature range. This device has an integrated 16-bit ADC that communicates to digital elements over I2C or SMBus. Designed for battery-operated systems, the TMP117 has 150 nA of quiescent current draw when in shutdown and requires 3.5 µA per 1-Hz conversion cycle.

To drive the TEC, the TPS54201 provides a constant current (1.5A) to drive the DRV8873 to perform a highly efficient heating and cooling element. The DRV8873 consists of four N-channel MOSFETs that drive motors bi-directionally with up to 10-A peak current with features such as integrated current sensing which eliminates the need for two external shunt resistors, saving bill-of-materials cost and space. Please refer to the application report, “Driving a Peltier Element (TEC): Efficiency and Aging,” for more information.

As the amplification occurs, fluorescence tags targeting the signature of the pathogen are excited by a light source; a photodiode or set of photodiodes detect the fluorescence. The signal level versus the time or cycles of amplification provides an indication of the initial concentration of the given pathogen in the sample. Being able to measure such a signal level with only a few target DNA segments in the sample, early in the amplification process, reduces the time required to obtain a positive result (target genomic material identified). The DDC family comprises devices that can simultaneously sample current from 1 to 256 diodes, integrating into one circuit the current amplifiers and the ADC. These devices provide very low input referred noise (a fraction of a picoampere rms), low input bias current (0.1 pA) and a high-linearity ADC with up to 24-bit resolution.

The complexity involved in this type of assay extends across several scientific disciplines and is beyond the scope of this post. Nevertheless, we hope that we have pointed you in the right direction when trying to select some of the more critical electronic components for instrument design.

Additional resources

- Read the application report, “RTD Class-AA Replacement With High-Accuracy Digital Temperature Sensors in Field Transmitters.”

- Check out the DRV8873xEVMand DDC11xEVM-PDK user’s guides.

- Learn more about in-vitro diagnostics.