SSZT368 november 2019 LMR33610 , LMR33620 , LMR33630 , LMR33640 , LMR36520

The Industry 4.0 revolution enables the capture and analysis of data about various machines, resulting in faster, more flexible, more reliable and more efficient processes to produce higher-quality goods at lower costs. Industry 4.0 does create some challenges at the system level, however, for engineers designing power supplies with DC/DC step-down regulators. These challenges include the need to improve reliability, enhance heavy load efficiency to minimize thermal dissipation, and provide a faster transient response to achieve a smaller output capacitance.

1. Think about wide input voltage and high current.

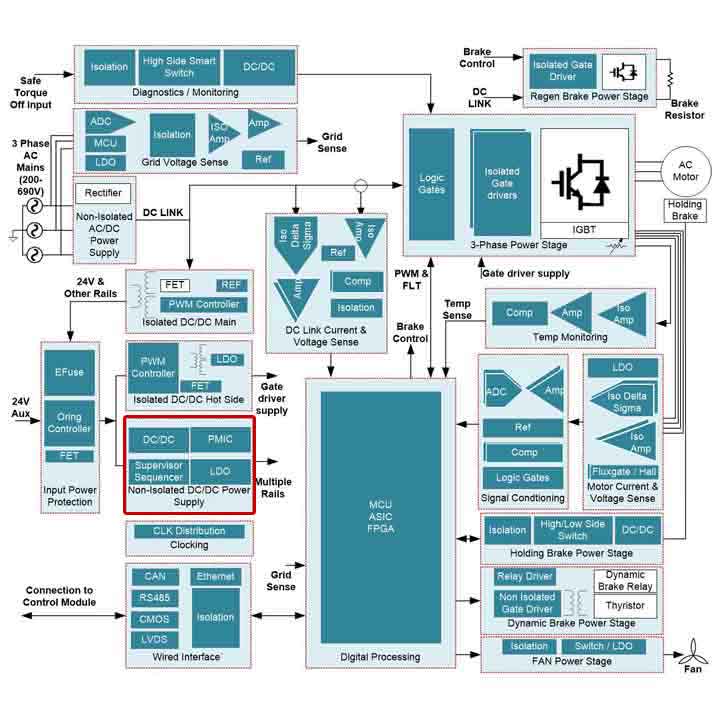

Figure 1 shows a simplified power architecture for a servo drive power stage, which is powered by a 24-VDC auxiliary power source. The 24-V can also be generated by the DC Bus voltage by using an isolated power supply. The first stage is the field input protection circuit; the second stage is the nonisolated DC/DC field power supply.

Figure 1 Servo drive module power architecture

Figure 1 Servo drive module power architectureThe power supply typically needs to support 36-V or even up to 60-V operation and requires DC/DC converters rated for higher current (>1 A) to protect against unexpected power surges caused by long cables, hot plugs and ringing – familiar scenarios for engineers designing power solutions for the industrial world. As such, when designing a power supply for industrial applications like servo or AC drives, consider step-down converters that offer a wide input voltage.

The LMR36520 has a transient tolerance as high as 70 V, which helps protect against overvoltages and meets the surge immunity requirements of International Electrotechnical Commission 61000-4-5. If 36 VIN is acceptable for your application, you can pick converters based on the required load conditions. The LMR33610, LMR33620, LMR33630 and LMR33640 enable you to reuse most of your layout, significantly simplifying your system-level schematic and layout design and reducing R&D efforts.

2. Choose devices with fast transient response.

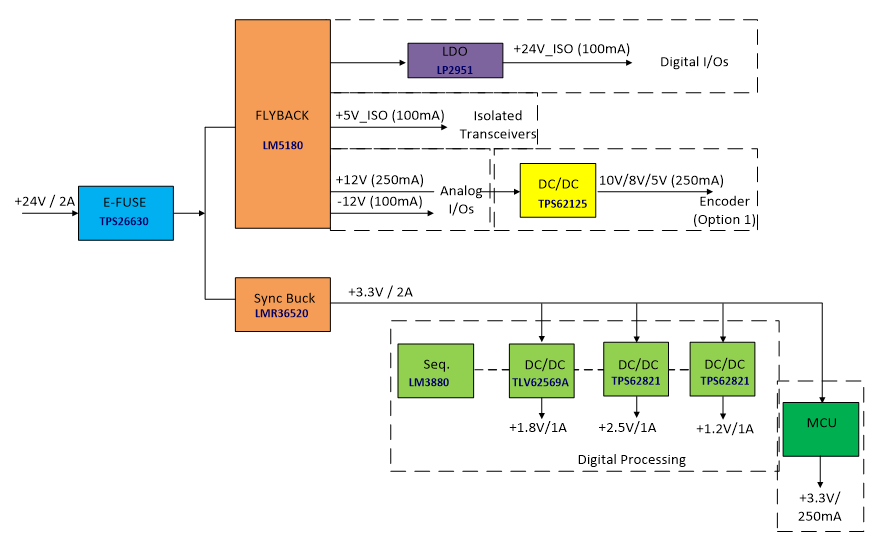

Because of their ruggedness, AC drives can be used to control the induction motors used in processing plants. Besides that, AC drives control the speed of an AC motor by varying the output voltage and frequency through a sophisticated microcontroller (MCU)-controlled electronics device. Figure 2 shows the power-supply design for a safety MCU in AC drive system. This safety power supply (3.3 V) is designed to power up the safety MCU and other loads. The power supply can also be used for servo drives besides the AC drive.

Figure 2 Power-supply design for servo

drive system

Figure 2 Power-supply design for servo

drive systemHigher supply voltage can affect the normal operation of an MCU or even damage it, when the supply voltage is higher than the MCU’s absolute maximum supply voltage rating. Lower supply voltage, in turn, can negatively impact MCU’s reset circuits’ or peripheral circuits’ (such as general purpose input/output -GPIO) drive capability, preventing them from operating normally. Thus, when using a power supply to power both an MCU and another dynamic load, consider devices that offer fast transient performance. During the load transient, those devices will have lower overshoot/undershoot voltage at the output side, without impacting the operation of the MCU. Fast transient performance reduces the pressure on the MCU and secondary point of load regulators, improving system robustness and potentially eliminating the need for protection devices such as clamping diodes.

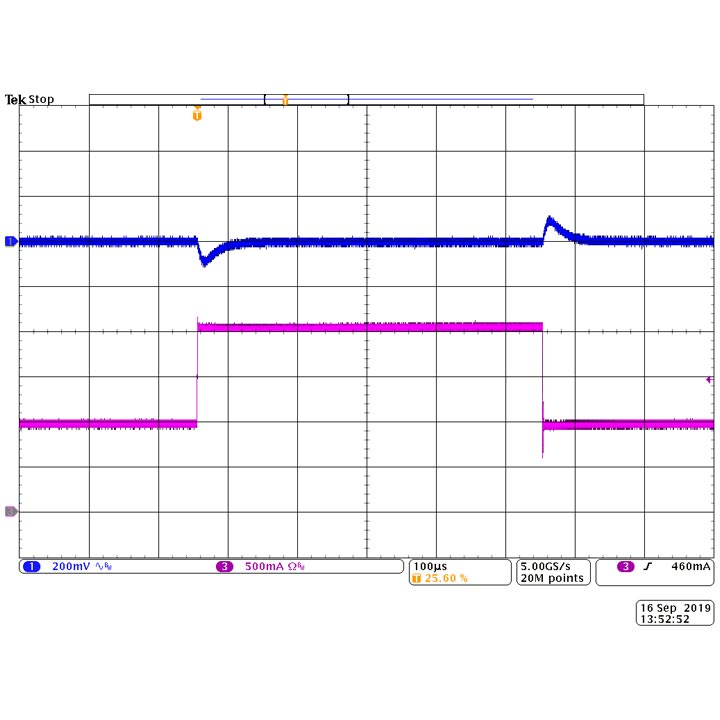

Figure 3 shows the load transient and switching waveforms of the LMR36520. When the load increases from 1 A to 2 A at a 1-A/µs slew rate, there is only 100 mV of overshoot and undershoot.

Figure 3 LMR36520 load transient

Figure 3 LMR36520 load transient3. Don’t forget about ground protection.

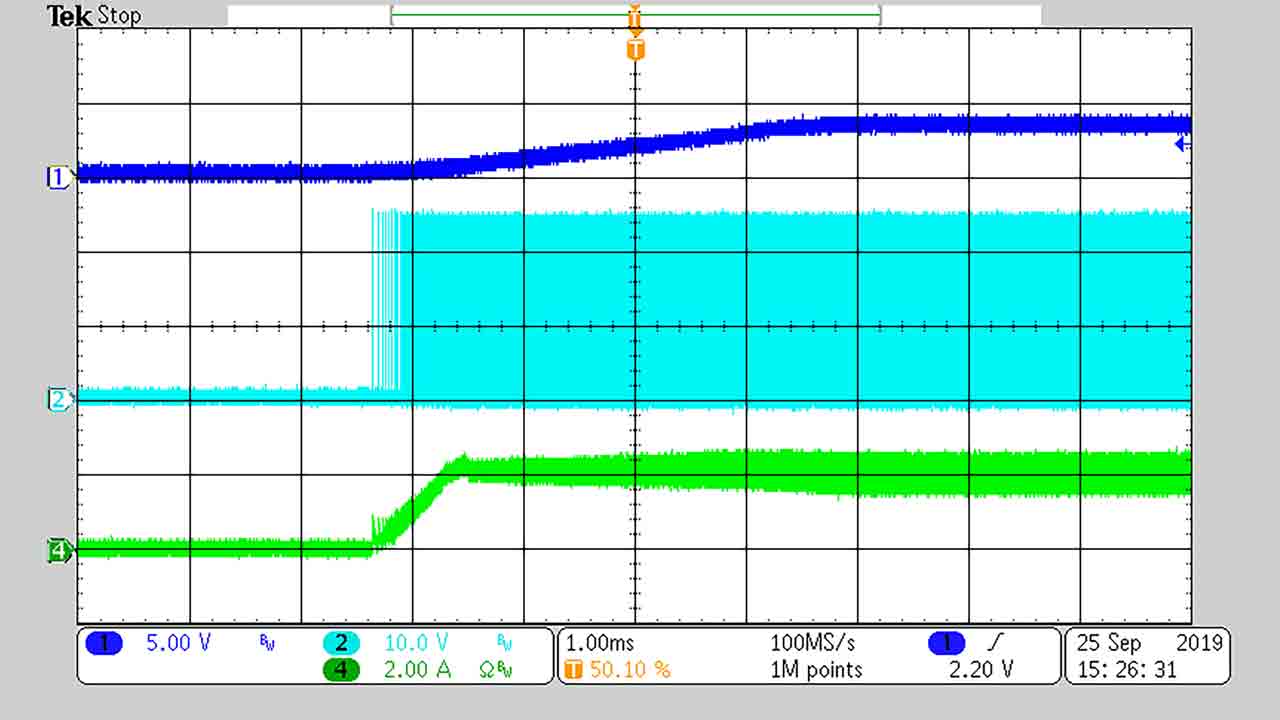

The power supply will also need output-short-to-ground protection. The power-supply output from Figure 2 also powers buffers and communication interfaces. In a real-life industrial environment, an operator might forget to turn off the power when changing some component, which could cause the power supply’s output (3.3 V or 5 V, depending on the MCU) to short to ground. When a 3.3-V or 5-V load is shorted to ground and released, you don’t want to see overshoot at the 3.3-V or 5-V rail because that might damage the MCU, which usually has an absolute maximum operation input voltage of 6 V. To prevent overshoot, look for buck converters with properly designed hiccup-protection features. As Figure 4 shows, the LMR36520 has good output-short-to-ground recovery protection.

Figure 4 LMR36520 short-to-ground waveform

Figure 4 LMR36520 short-to-ground waveformConclusion

When designing the power supply for a servo and AC drive, think through the potential impact of your design. A wide input voltage, higher output current, fast transient performance and good short-to-ground protection are the key factors you should consider during development.

Additional resources

- Read the technical article, “The buck regulator efficiency/size tradeoff dilemma.”

- Check out the Analog Design Journal article, “Low-IQ synchronous buck converter enables intelligent field sensor applications.”