SSZT863 december 2017 DRV10983 , DRV10983-Q1 , DRV10987

In part 1 of the integrated intelligence motor driver blog post series, I discussed electromagnetic interference (EMI) management and various ways to reduce electromagnetic radiation using integrated solutions. In the second and third installments, I will discuss motor startup techniques for driving brushless DC (BLDC) motors in sensorless mode.

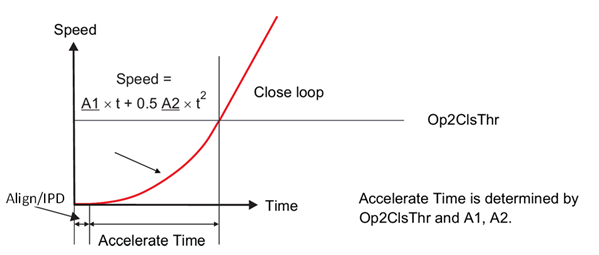

Advanced sensorless algorithms, which are based on an estimation of back-electromotive force (BEMF), need a minimum value of BEMF to accurately estimate the position of the rotor for driving BLDC motors in 180-degree sinusoidal mode. To get a minimum BEMF value, the motor is initially driven through an open-loop phase until it reaches a minimum speed, followed by commutation in a closed loop using the estimated BEMF. Motor startup is divided into two phases: first, when the motor is at a standstill; and second, when it starts acceleration without BEMF information, as shown in Figure 1.

Figure 1 Startup Profile for a BLDC

Motor, as Shown in the Data Sheets of TI’s DRV10983-Q1, DRV10987 and

DRV10983

Figure 1 Startup Profile for a BLDC

Motor, as Shown in the Data Sheets of TI’s DRV10983-Q1, DRV10987 and

DRV10983During an open loop, the motor is driving without any information about the position of the rotor. This phase of open-loop commutation, also known as blind commutation, is very important because it is directly related to system reliability. If blind commutation is not configured correctly, the motor will start, lose sync and stall.

It is critical that during the open-loop state, the driver can accelerate the motor to a speed high enough for accurate BEMF estimation. It should also be able to support a load during this open-loop state. After reaching hand-off speed, the driver switches from an open to a closed loop. This hand-off speed will vary based on the torque constant of the motor (Kt); that is, motors with a higher torque constant need a lower hand-off speed, and vice versa.

As a result, the driver should be capable of providing variable speed profiles to support open-loop acceleration, adjustable current to support a variety of loads and an adjustable hand-off speed. For an integrated driver, you can achieve this kind of blind startup by configuring a handful of electrically erasable programmable read-only memory (EEPROM) registers. This feature is available in integrated drivers like the DRV10983-Q1, DRV10987 or DRV10983, or any other sensorless driver from the DRV10x family.

Coefficients A1 and A2 set the rate of acceleration and Op2ClsThr sets the hand-off speed, otherwise known as the open- to closed-loop threshold. See Equation 1:

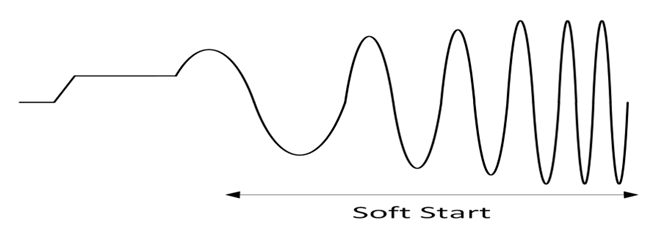

One of the advantages of having second-order acceleration, as shown in Equation 1, is that it enables you to drive the motor to match the mechanical load profiles. It also allows soft start, which means that the motor will start at a slower speed and gradually increase the rate of acceleration as the speed increases, as shown in Figure 1 and Figure 2. This feature is useful for motors that have high inertia loads.

Figure 2 Soft Start During Open-loop

Acceleration

Figure 2 Soft Start During Open-loop

AccelerationAn integrated driver is not only capable of starting the motor using blind commutation; it is also capable of starting the motor smoothly through soft open-loop acceleration. These capabilities will help spin a variety of motors with different loads. In the next installment, I will explore different techniques to start a motor for standstill position.

Additional Resources

- Download the DRV10983-Q1 data sheet.

- Start spinning those BLDC motors with the DRV10983-Q1 evaluation module (EVM).

- Watch a video on how to quickly spin motors using DRV10983-Q1 BLDC motor driver EVM.

- Read part oneand part three of this blog series.