SSZT967 september 2017 LMH0397 , LMH1208 , LMH1218 , LMH1219 , LMH1228 , LMH1297

As 4K video becomes the norm for the professional video industry, high-quality serial digital interface (SDI) components and meticulous board layout are imperative for a high-performance end product. In addition, flexibility, scalability and cost savings are necessary to maximize design reuse, whether you are looking to expand your 12G product portfolio or aiming to transition from 3G-SDI to 12G-SDI.

A bidirectional input/output (I/O) addresses these critical needs. A bidirectional I/O is a device that you can configure as either a receive cable equalizer or a transmit cable driver through the same port. Let’s look at how this flexible device simplifies 4K video interfaces.

Reason No. 1: to Enable Design Flexibility

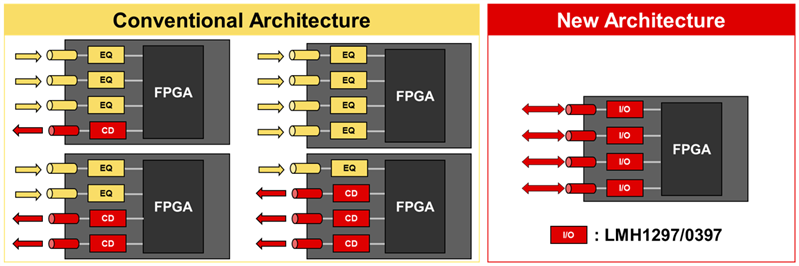

Figure 1 With a Bidirectional I/O, a Single Design Supports Multiple Input and Output Port Configurations

Figure 1 With a Bidirectional I/O, a Single Design Supports Multiple Input and Output Port ConfigurationsTI’s latest 12G bidirectional I/O, the LMH1297, also enables dynamic port provisioning, meaning that end users can configure the port as an input or output on the fly. This design flexibility and scalability reduces both overall development time and the cost of stocking unique boards to support each port-configuration combination.

Reason No. 2: to Minimize Board Space and Bill-of-materials Cost

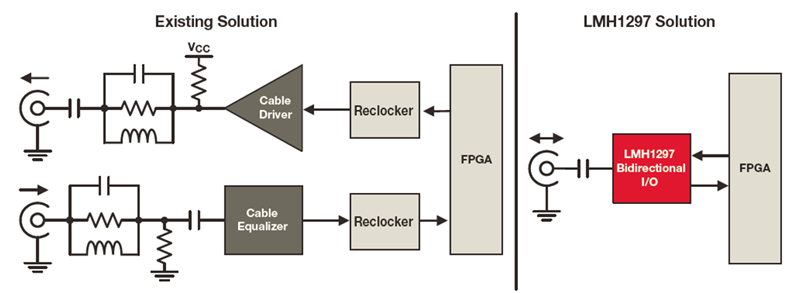

Figure 2 TI’s Bidirectional I/O Reduces the Overall Number of Ports, While Its On-chip Integration Reduces the Number of External Passive Components Required.

Figure 2 TI’s Bidirectional I/O Reduces the Overall Number of Ports, While Its On-chip Integration Reduces the Number of External Passive Components Required.TI’s new 12G bidirectional I/O takes minimization and cost savings a step further. The LMH1297 has an integrated reclocker, return loss network and terminations. The integrated reclocker ensures a clean output signal with minimal jitter. Meanwhile, the integrated return loss network and terminations eliminate the need for an external return loss network, not to mention time spent fine-tuning these network parameters.

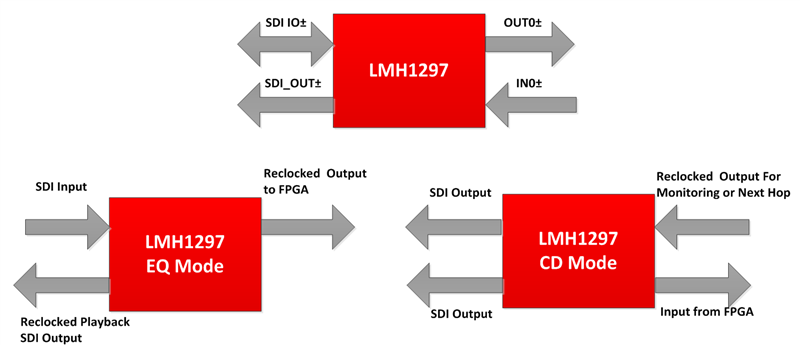

The LMH1297 integrates an additional 75Ω loop-through cable driver output and a 100Ω loopback printed circuit board (PCB) driver output. You can use these additional outputs to expand signal distribution efficiently and improve system diagnosis capability, without extra cable drivers or reclockers to support the same system functionality. Applications for the additional loop-through and loopback driver are shown in Figure 3.

Figure 3 The Additional Driver Outputs in the LMH1297 Simplify Signal Distribution When the I/O Is Configured as Either an Input (EQ Mode) or Output (CD Mode).

Figure 3 The Additional Driver Outputs in the LMH1297 Simplify Signal Distribution When the I/O Is Configured as Either an Input (EQ Mode) or Output (CD Mode).Furthermore, TI’s bidirectional I/O is implemented on a single-die solution. Traditionally, bidirectional I/Os are designed as a multichip module (MCM), which adversely affects overall performance compared to a stand-alone cable equalizer or cable driver. With the single-die approach, the LMH1297 achieves performance equivalent to or exceeding that of many other stand-alone cable equalizers and drivers. These features are offered in a 5mm-by-5mm very thin quad flat no-lead (WQFN) package.

Reason No. 3: to Provide an Easy Upgrade Path

Figure 4 LMH1297 Pin and Software Compatible Portfolio

Figure 4 LMH1297 Pin and Software Compatible PortfolioWhy re-invent the wheel for each project? Maximize your efficiency and simplify your next SDI design with a bidirectional I/O.

To learn more about new interface products and get an edge in your 4K transition, visit TI’s SDI portfolio or log in to post a comment below or talk with other engineers in the TI E2E™ Community High Speed Interface forum.

Additional Resources

- Learn about TI’s latest featured 3G-SDI and 12G-SDI products.

- Find out more about a 4K field programmable gate array (FPGA) mezzanine card (FMC) development module supporting the LMH1218 and LMH1219.

- Check out the blog post, “Three things to consider when upgrading to 4K Ultra HD 12G-SDI interfaces.”

- Read The Broadcast Bridge article, “What You Need To Know About Return Loss.”