SSZTA38 June 2017 INA181 , INA199 , INA210

With battery-operated devices now being an essential part of our daily life, the burden of charging these devices is receiving more attention than ever. A good number of new approaches have emerged in the last couple of years to address the long charging times to enable users to get their devices fully charged in minutes rather than hours.

In this post, I’ll highlight trends in fast charging and the essential role that precise constant current (CC) regulation plays to help enable fast, safe and cost-effective solutions to charge devices faster.

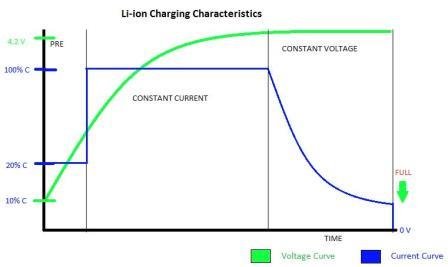

Batteries generally go through two phases while charging: constant current (CC) and constant voltage (CV). Figure 1 shows the typical charging curve for a 4.2V lithium-ion (Li-ion) battery. CC is used roughly for the first 67% of charging, when most of the energy transfers from the charger to the battery. CV kicks in during the last 33% of the remaining charging time to help charge the battery fully and maintain a full charge. Some chargers pump small currents (also called trickle charging) during CV to account for discharging currents and keep the battery voltage fully charged. The time it takes for the battery to fully charge depends on its capacity and maximum allowable charging current, which is a function of battery chemistry and ambient temperature. For example, if you have a Li-ion battery with a capacity of 3000mAh and a charge rate of 0.8C (where C refers to the current needed to charge the battery in one hour, which is the default rate battery manufacturers recommend to prolong battery life), the battery will need two to three hours to fully charge.

Figure 1 Typical Li-ion Battery

Charging Curve

Figure 1 Typical Li-ion Battery

Charging CurveThe latter paragraph describes a typical charging scenario where the charging rate is considered normal with limited handshaking. Newly introduced methods maximize charging time by pushing more energy to the battery during the CC phase. These methods use either proprietary charging algorithms or follow a mainstream standard, like the USB Power Delivery Programmable Power Supplies (PPS) standard. Both the wall charger and the device perform continuous handshaking to intelligently communicate the battery’s needs and maximize charging efficiency.

The two main fast charging methods are high voltage and low current (legacy method), and high current and low voltage (new mainstream trend). The first method uses the existing charging cable and limits the current to about 2A, while increasing the voltage levels up to 15V. The issue with this method is the high heat dissipation from the required voltage-conversion stage at the device side, which decreases both battery life and the maximum allowable energy transferable to the battery.

The second method uses a voltage close to the battery’s voltage and a higher current that can flow to the battery directly. This method is usually known as direct or fast charging. This method enables higher charging rates at cooler temperatures because there is no voltage conversion on the device side. However, fast charging does require special charging cables to enable higher currents to flow. The idea is to try to charge the battery at a rate as close as possible to the maximum allowable rate to minimize charging time.

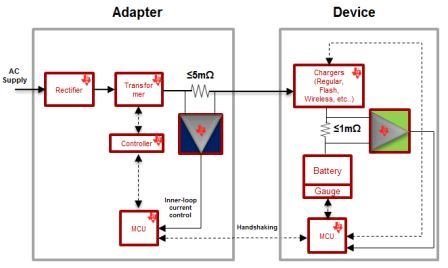

Given fast charging’s cooler temperature profile; it is becoming more and more popular, with most existing standards adopting it. Figure 2 shows a high-level block diagram of a flash-charging system.

Figure 2 High-level Block Diagram of a

Fast-charging Solution

Figure 2 High-level Block Diagram of a

Fast-charging SolutionAs you can see in Figure 2, a precise current-control loop is necessary to enable faster charging times, and to add an extra layer of protection on top of what other blocks like battery chargers and fuel gauges are already using. Although you can integrate the current-sensing function, it’s hard to match the level of accuracy that dedicated current-sensing solutions can provide using small shunt resistances to minimize heat dissipation, and the ability to monitor the current on the high side.

TI offers a variety of dedicated current sensors that fit well in fast charging. These solutions include the INA210 family, which offers great accuracy across a wide dynamic range; the INA199, which has a great combination of accuracy and cost; and the new INA181 family, which offers the best value in terms of bandwidth, accuracy and price. In this application, the INA181’s wide 350kHz closed-loop bandwidth enables the detection of the CC signal’s fast ripples – information that you need to maximize the CC by minimizing the guard band for battery protection and safety.

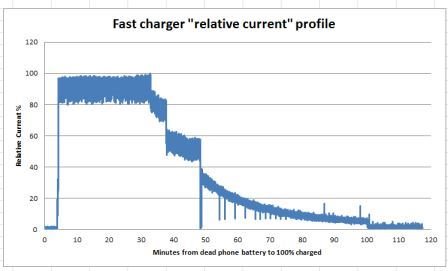

Figure 3 shows a typical flash-charging signal as seen from the output of a wall charger.

Figure 3 Fast-charging Current Profile

Example

Figure 3 Fast-charging Current Profile

ExampleTo sum it all up, the main limitation of today’s fast-charging methods is heat dissipation close to the battery, which limits the maximum allowable energy transferred and thus minimizes the charging time. Also, high temperatures have safety and battery-life degradation concerns. Fast charging is a promising method because it allows a high level of energy transfer at relatively cooler temperatures while maximizing charging efficiency and minimizing charging time. Enabling this high efficiency requires a precise current-control loop, which is best achieved by dedicated current sensors.

To get posts like this delivered to your inbox, sign in and subscribe to Analog Wire.

Additional Resources

- Learn more about TI’s portfolio of current-sense amplifiers.

- Get started with the Current Sense Amplifiers video training series.

- Read these TI TechNotes: