SWRU546E October 2018 – May 2022 AWR6843 , AWR6843AOP , IWR6443 , IWR6843 , IWR6843AOP

- Trademarks

- 1Getting Started

-

2MMWAVEICBOOST

- 2.1 Hardware

- 2.2 Block Diagram and Features

- 2.3 Muxing Scheme for Multiple Sources

- 2.4 Using the MMWAVEICBOOST With the Starter Kit

- 2.5 Interfacing with the DCA1000EVM

- 2.6 Power Connections

- 2.7

Connectors

- 2.7.1 20-Pin LaunchPad and Booster Pack Connectors (J5, J6)

- 2.7.2 60-Pin High Density (HD) Connector (J4 and J17)

- 2.7.3 60-Pin High Density (HD) Connector (J10)

- 2.7.4 MIPI 60-Pin Connector (J9)

- 2.7.5 TI 14-Pin JTAG Connector (J19)

- 2.7.6 CAN Connector (J1 and J2)

- 2.7.7 Ultra-Miniature Coaxial Connector (J3)

- 2.8 Jumpers, Switches and LEDs

- 3xWR6843ISK / IWR6843ISK-ODS REV C

-

4xWR6843AOPEVM Rev G

- 4.1 Hardware

- 4.2 Block Diagram

- 4.3 PCB Storage and Handling Recommendations

- 4.4 Heat Sink and Temperature

- 4.5 xWR6843AOPEVM Antenna

- 4.6 Switch Settings

- 4.7 xWR6843AOPEVM Muxing Scheme

- 4.8 Modular, DCA1000EVM and MMWAVEICBOOST Mode

- 4.9 Known Issues: Spurious Performance

- 4.10 PC Connection

- 4.11 REACH Compliance

- 4.12 Regulatory Statements with Respect to the xWR6843AOPEVM Rev G

- 5xWR6843AOPEVM Rev F

- 6IWR6843ISK / IWR6843ISK-ODS (deprecated)

- 7IWR6843AOPEVM (Deprecated)

- 8TI E2E Community

- 9Certification Related Information

- Revision History

2.4.3 MMWAVEICBOOST and Antenna Module Connections for Modular Testing

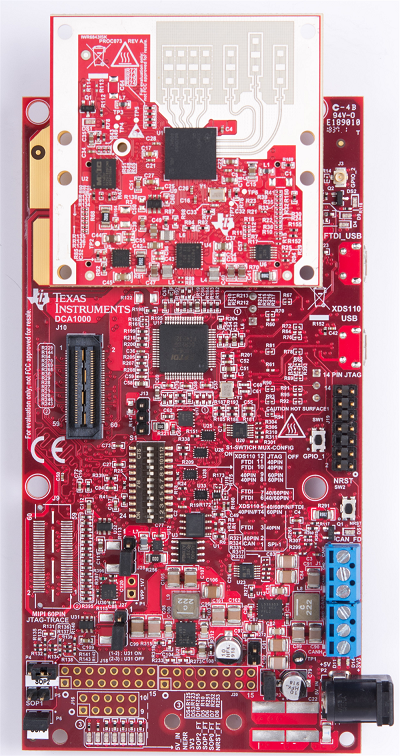

A compatible antenna module can be stacked on top of the MMWAVEICBOOST board using the two 60-pin HD connectors and 12 nuts, four washers, and four M3 screws (for improving the thermal performance). Connectors have a pin number marking shown in Figure 2-18 to prevent the misalignment of the pins or reverse connection. Figure 2-10 shows the integration of MMWAVEICBOOST and starter kit. The starter kit is powered by the 3.3-V supply. There is one micro USB cable to XDS110 (J11) to run the out-of-box demo, and one micro USB cable to FTDI (J12) for initiating controls from mmWave Studio. Digital controls from the MMWAVEICBOOST are initiated after the FTDI and XDS110 ports are detected in the device manager shown in Figure 2-9. The configuration of the MMWAVEICBOOST and starter kit are based on the analog mux settings and mux controls received from the dip switch (S1). To mux all the digital controls to the FTDI/XDS110 connector, set the mux control switch positions to ON/OFF, as shown in Table 2-1.

Figure 2-10 Integration of MMWAVEICBOOST and Starter Kit

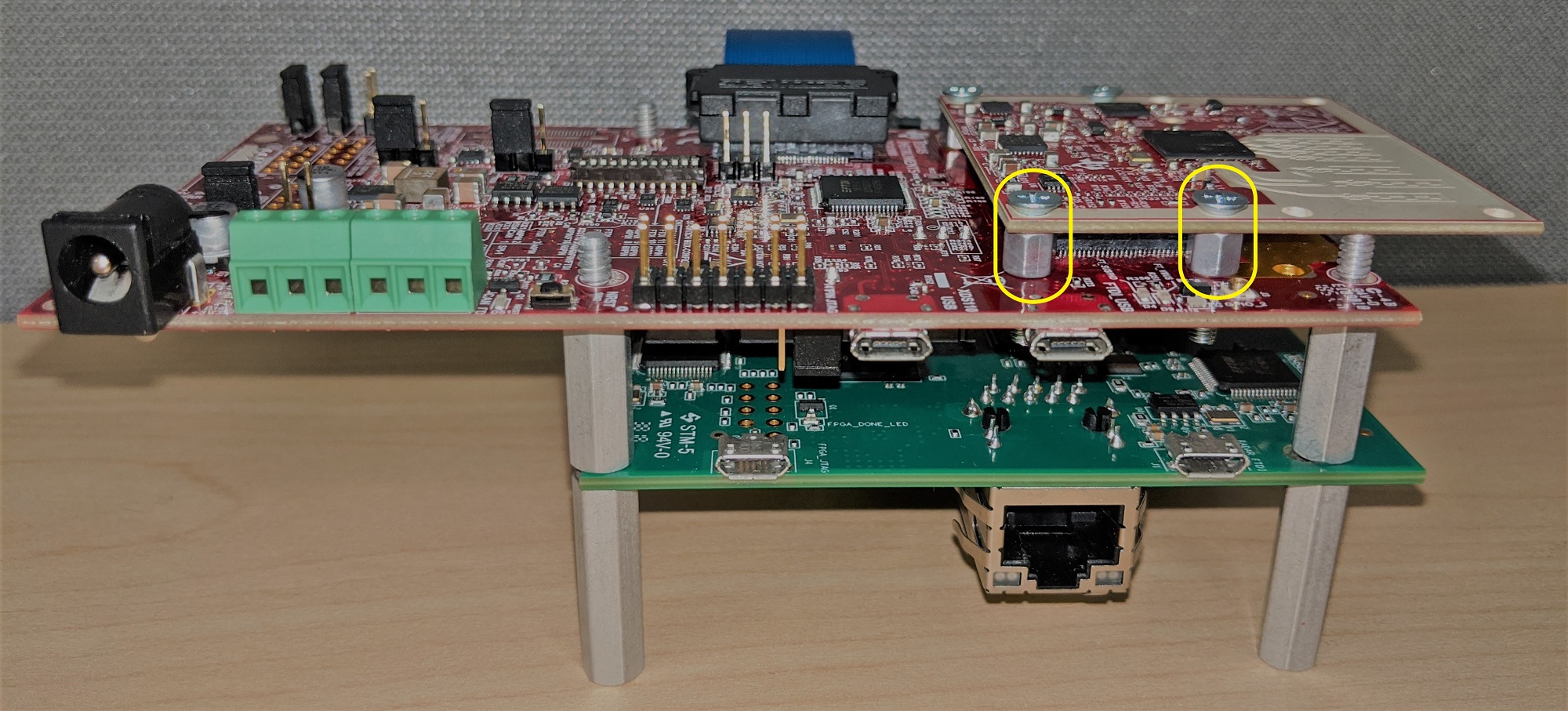

Figure 2-10 Integration of MMWAVEICBOOST and Starter KitFigure 2-11 shows the mechanical mounting of PCB. Spacers and screws can be used as heat sinking elements to spread the heat from the starter kit to carrier board, as shown in Figure 2-11.

Figure 2-11 Mechanical Mounting of the

PCB

Figure 2-11 Mechanical Mounting of the

PCB