TIDA029A july 2019 – june 2023 CC2640R2F-Q1 , CC2642R , CC2642R-Q1

- 1

- Bluetooth Angle of Arrival (AoA) Antenna Design

- Trademarks

- 1Introduction

- 2Angle of Arrival Antenna Design Considerations

- 3Dipole Antenna Array

- 4Calculating AoA From IQ Measurements

- 5References

- 6Revision History

4.2.2 PCB + RF Absorbing Material + Tin-Plated Copper Foil Compensated AoA

This hardware setup’s initial tests showed fairly linear results. Therefore, with compensation, AoA values are fairly accurate (depending on the frequency) from ±80°. Table 4-2 shows the compensation values used for each frequency.

Table 4-2 PCB + RF Absorbing Material + Tin-Plated Copper Foil AoA Compensation Values

| Frequency (MHz) | Channel | Gain | Offset |

|---|---|---|---|

| 2402 | 37 | 2.17 | –3.27 |

| 2404 | 0 | 2.17 | –3.34 |

| 2406 | 1 | 2.17 | –3.48 |

| 2408 | 2 | 2.17 | –3.54 |

| 2410 | 3 | 2.22 | –3.82 |

| 2412 | 4 | 2.22 | –3.54 |

| 2414 | 5 | 2.22 | –4.1 |

| 2416 | 6 | 2.22 | –4.1 |

| 2418 | 7 | 2.22 | –4.02 |

| 2420 | 8 | 2.22 | –4.16 |

| 2422 | 9 | 2.17 | –4.37 |

| 2424 | 10 | 2.17 | –4.44 |

| 2426 | 38 | 2.17 | –4.5 |

| 2428 | 11 | 2.17 | –4.22 |

| 2430 | 12 | 2.17 | –5.06 |

| 2432 | 13 | 2.17 | –4.56 |

| 2434 | 14 | 2.17 | –4.98 |

| 2436 | 15 | 2.17 | –4.2 |

| 2438 | 16 | 2.17 | –4.27 |

| 2440 | 17 | 2.13 | –4.62 |

| 2442 | 18 | 2.13 | –4.61 |

| 2444 | 19 | 2.17 | –4.12 |

| 2446 | 20 | 2.17 | –4.4 |

| 2448 | 21 | 2.17 | –4.39 |

| 2450 | 22 | 2.17 | –4.04 |

| 2452 | 23 | 2.17 | –4.46 |

| 2454 | 24 | 2.17 | –4.17 |

| 2456 | 25 | 2.17 | –4.03 |

| 2458 | 26 | 2.17 | –3.96 |

| 2460 | 27 | 2.17 | –3.75 |

| 2462 | 28 | 2.17 | –3.74 |

| 2464 | 29 | 2.17 | –3.88 |

| 2466 | 30 | 2.13 | –3.6 |

| 2468 | 31 | 2.13 | –3.73 |

| 2470 | 32 | 2.13 | –3.52 |

| 2472 | 33 | 2.13 | –3.52 |

| 2474 | 34 | 2.13 | –3.52 |

| 2476 | 35 | 2.08 | –3.38 |

| 2478 | 36 | 2.04 | –3.24 |

| 2480 | 39 | 2.04 | –3.03 |

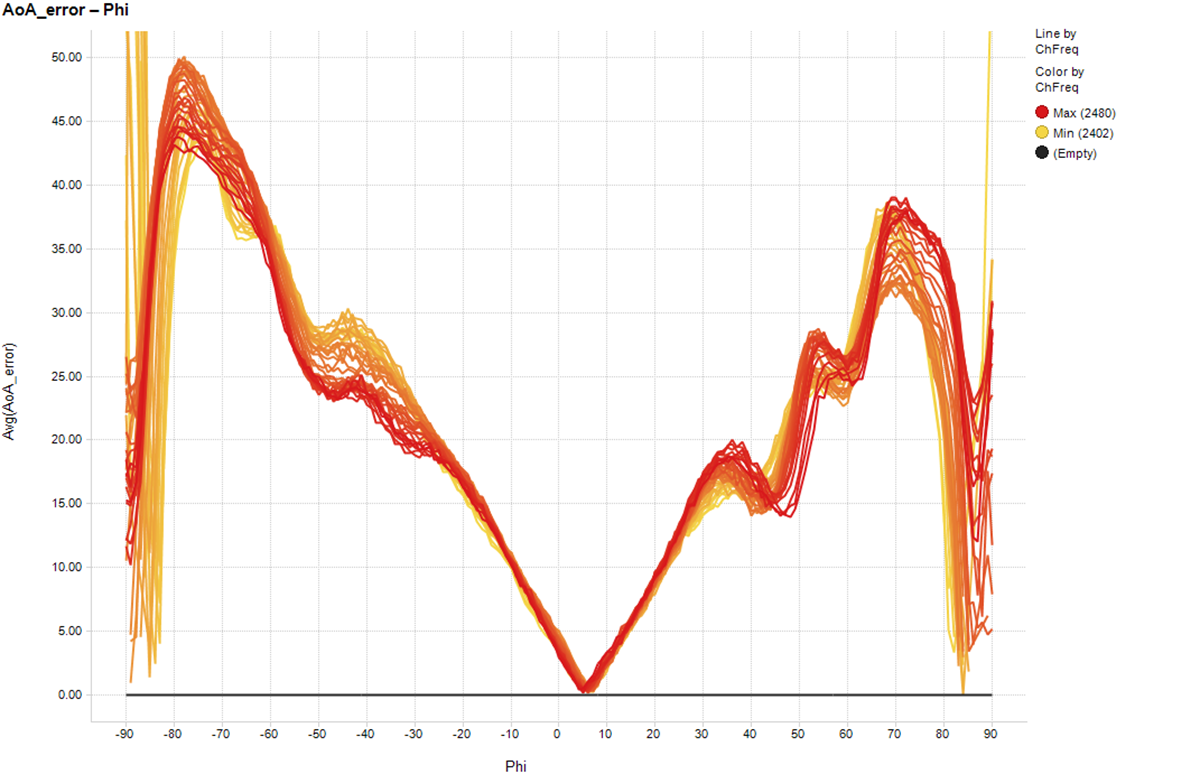

Figure 4-18 shows the uncompensated AoA error vs Phi and Figure 4-19 shows the compensated AoA error vs Phi.

Figure 4-18 PCB + RF Absorbing Material + Tin-Plated Copper Foil Uncompensated AoA Error

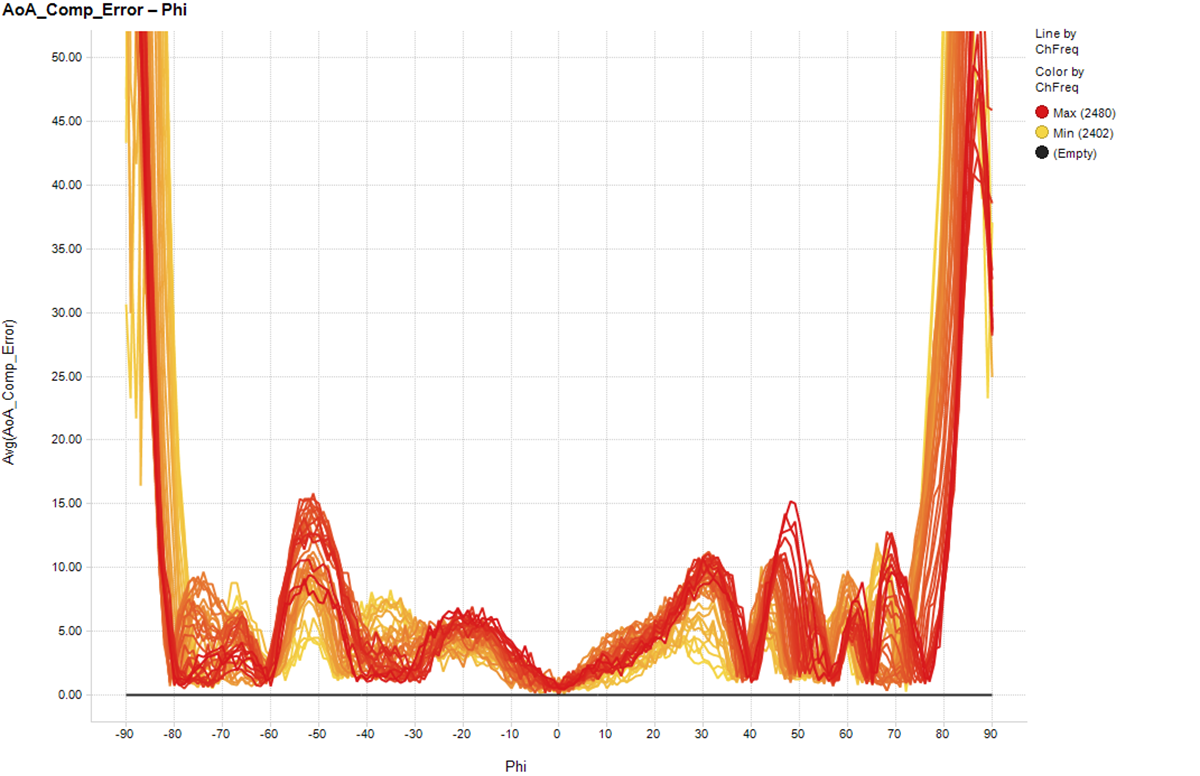

Figure 4-18 PCB + RF Absorbing Material + Tin-Plated Copper Foil Uncompensated AoA Error Figure 4-19 PCB + RF Absorbing Material + Tin-Plated Copper Foil Compensated AoA Error

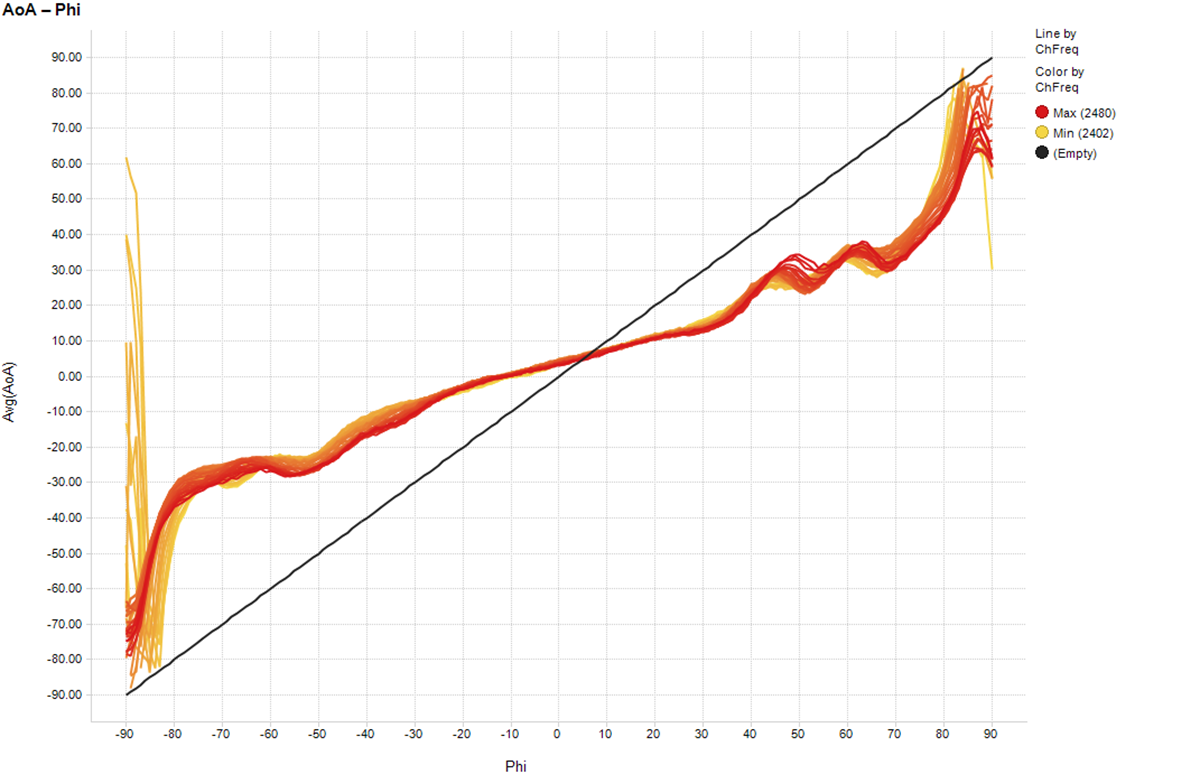

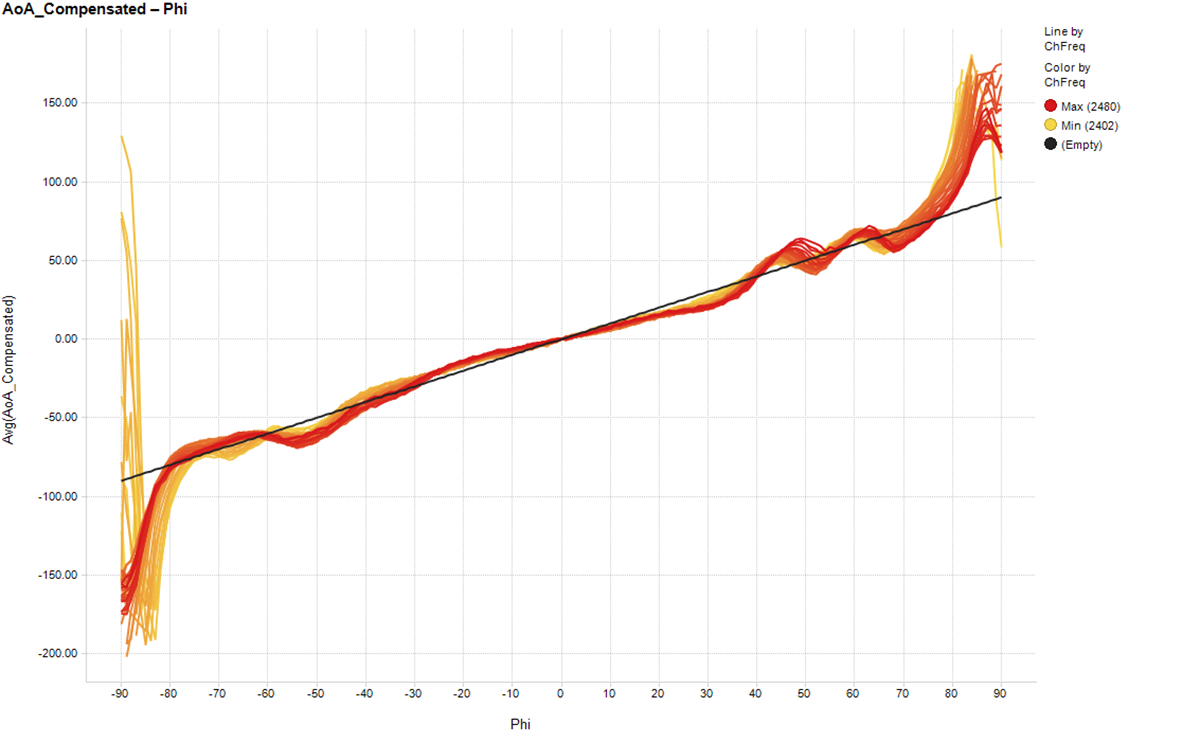

Figure 4-19 PCB + RF Absorbing Material + Tin-Plated Copper Foil Compensated AoA ErrorCompensation greatly reduces the AoA error and shows less than 10° of error over most frequencies from –80° to 75°. Figure 4-20 and Figure 4-21 show how the AoA data has been adjusted to be closer to the desired result.

Figure 4-20 PCB + RF Absorbing Material + Tin-Plated Copper Foil Uncompensated AoA Results Over all Bluetooth Low Energy Channels

Figure 4-20 PCB + RF Absorbing Material + Tin-Plated Copper Foil Uncompensated AoA Results Over all Bluetooth Low Energy Channels Figure 4-21 PCB + RF Absorbing Material + Tin-Plated Copper Foil Compensated AoA Results Over all Bluetooth Low Energy Channels

Figure 4-21 PCB + RF Absorbing Material + Tin-Plated Copper Foil Compensated AoA Results Over all Bluetooth Low Energy Channels