SLLSET0D March 2016 – April 2021 TCAN1051-Q1 , TCAN1051G-Q1 , TCAN1051GV-Q1 , TCAN1051H-Q1 , TCAN1051HG-Q1 , TCAN1051HGV-Q1 , TCAN1051HV-Q1 , TCAN1051V-Q1

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Parameter Measurement Information

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3 Feature Description

- 8.4 Device Functional Modes

- 9 Application Information Disclaimer

- 10Power Supply Recommendations

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

9.2.2.1 CAN Termination

The ISO 11898 standard specifies the interconnect to be a twisted pair cable (shielded or unshielded) with 120-Ω characteristic impedance (ZO). Resistors equal to the characteristic impedance of the line should be used to terminate both ends of the cable to prevent signal reflections. Unterminated drop lines (stubs) connecting nodes to the bus should be kept as short as possible to minimize signal reflections. The termination may be on the cable or in a node, but if nodes may be removed from the bus, the termination must be carefully placed so that two terminations always exist on the network.

Termination may be a single 120-Ω resistor at the end of the bus, either on the cable or in a terminating node. If filtering and stabilization of the common mode voltage of the bus is desired, then split termination may be used. (See Figure 9-2). Split termination improves the electromagnetic emissions behavior of the network by eliminating fluctuations in the bus common-mode voltages at the start and end of message transmissions.

Figure 9-2 CAN Bus Termination Concepts

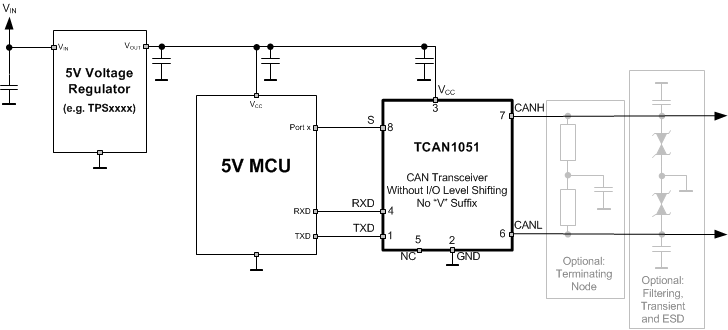

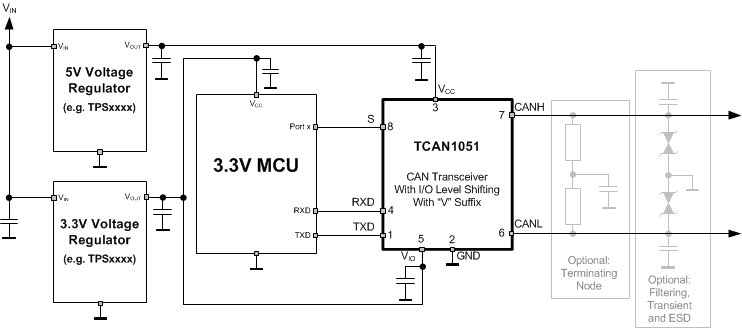

Figure 9-2 CAN Bus Termination ConceptsThe TCAN1051 family of transceivers have variants for both 5-V only applications and applications where level shifting is needed for a 3.3-V micrcontroller.

Figure 9-3 Typical CAN Bus Application Using 5 V CAN Controller

Figure 9-3 Typical CAN Bus Application Using 5 V CAN Controller Figure 9-4 Typical CAN Bus Application Using 3.3 V CAN Controller

Figure 9-4 Typical CAN Bus Application Using 3.3 V CAN Controller