SLVAFM6 may 2023 TPS62A02 , TPS631000

4.3 High Efficiency Power Rails

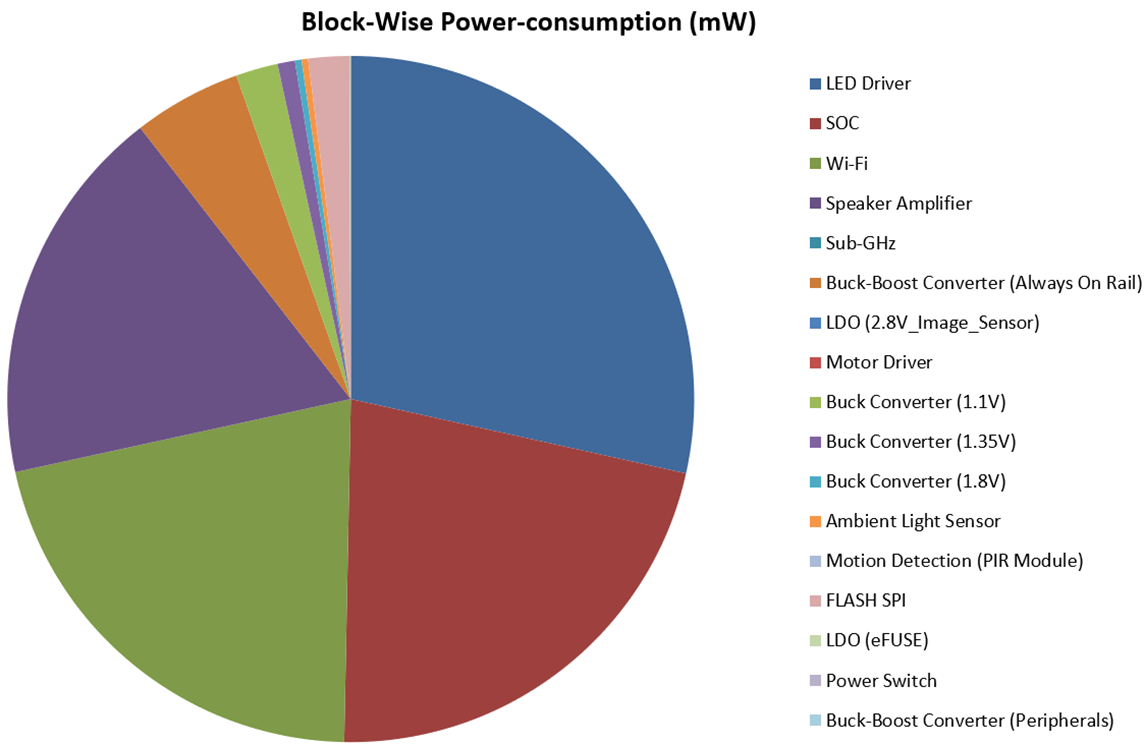

Based on the prior video working mode, a reasonable high-efficiency power rails increases battery working lifetime. From Figure 4-7, the most energy is used by LED lighting, video processing, always-on Wi-Fi and Audio. Except always-on power rails, others mostly take a big current when the power rails are awake and fully running. Especially for low voltage output rails, the efficiency is very low if not carefully selecting the correct component. Although cost is a critical factor in the product, total equivalent power efficiency is also a key feature which have a big influence for battery lifetime.

Figure 4-7 An Example of Battery Powered Camera Energy Consumption Pie Chart

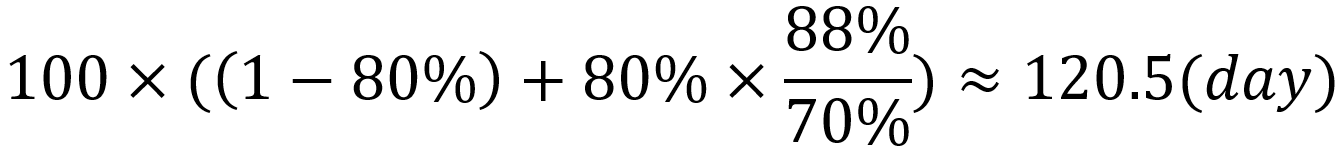

Figure 4-7 An Example of Battery Powered Camera Energy Consumption Pie ChartFor example, assume designed total efficiency is 70%, energy consumption without always-on power rails assumes taking 80% in total energy, real battery working lifetime is 100 days. If increasing total power efficiency to 88%, battery lifetime:

Total battery working lifetime increases over 20%. Although this is just a rough calculation because by not adding some sleep, quiescent, shutdown current changing, but the calculator also shares that the total power efficiency is very important in battery powered camera.

Besides using high-power efficiency and low shutdown current components in video processing circuits and using high-power efficiency and low-quiescent current components in an always working circuit. A good power structure can help improve efficiency, for example, in Figure 4-1, if PIR LDO and Image sensor LDO is placed before buckboost and directly connected with the battery, the power structure can provide good noise rejection, but efficiency is a little worse at times.

A good power management strategy can improve battery lifetime based on a designed for power consumption structure. In addition, Wi-Fi SOC low power consumption feature and working mode also have big impact for battery lifetime.