SLYT820 February 2022 AMC22C11 , AMC22C12 , AMC23C10 , AMC23C11 , AMC23C12 , AMC23C12-Q1 , AMC23C14

- 1Introduction

- 2Introduction to electric motor drives

- 3Understanding fault events in electric motor drives

- 4Achieving reliable detection and protection in electric motor drives

- 5Use case No. 1: Bidirectional in-phase overcurrent detection

- 6Use case No. 2: DC+ overcurrent detection

- 7Use case No. 3: DC– overcurrent or short-circuit detection

- 8Use case No. 4: DC-link (DC+ to DC–) overvoltage and undervoltage detection

- 9Use case No. 5: IGBT module overtemperature detection

3 Understanding fault events in electric motor drives

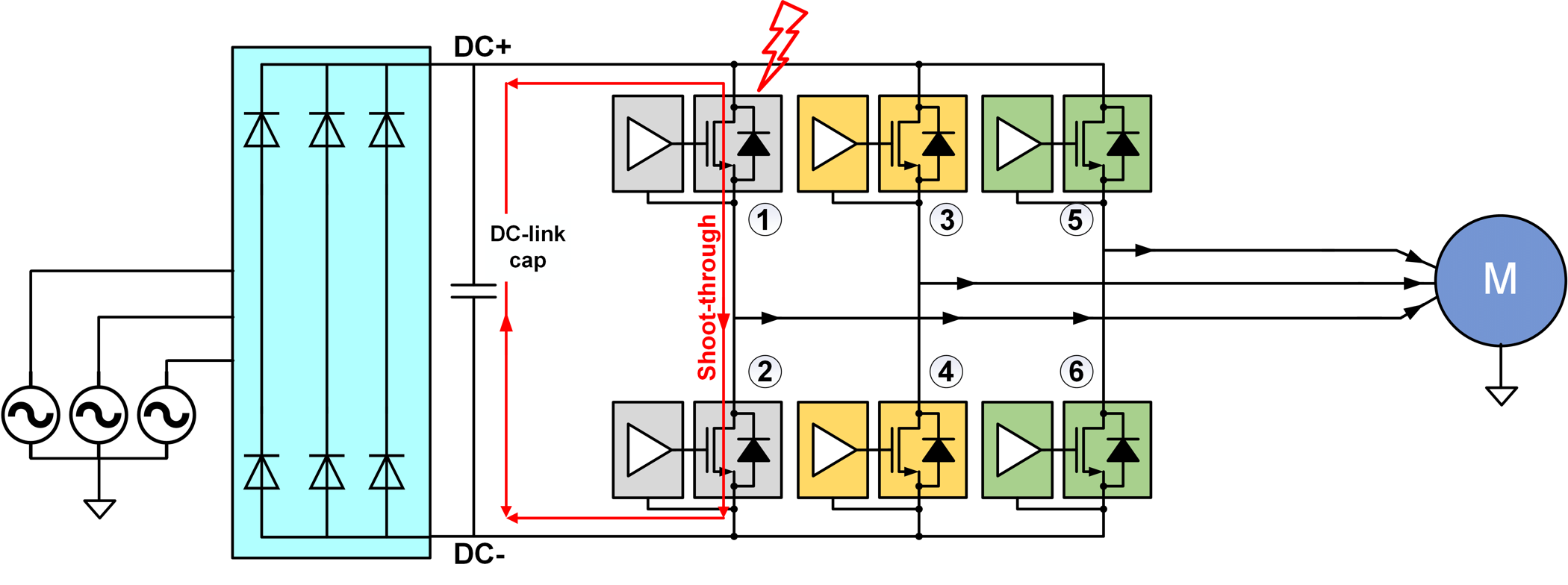

Electric motor drives are susceptible to several electrical fault events. As shown in Figure 3-1, a shoot-through fault occurs when the adjacent power switching transistors, 1 and 2, accidentally turn on at the same time. This fault can occur because of several reasons: electromagnetic interference, a malfunction in the microcontroller controlling the switching transistors, or simply worn-out switching transistors. This fault short-circuits the DC-link capacitor and can cause catastrophic failure, resulting in excessive heating, fire or even an explosion. Thus, it is imperative to detect shoot-through faults and take corrective actions such as turning off the power switching transistor very quickly.

Figure 3-1 A shoot-through fault in

electric motor drives.

Figure 3-1 A shoot-through fault in

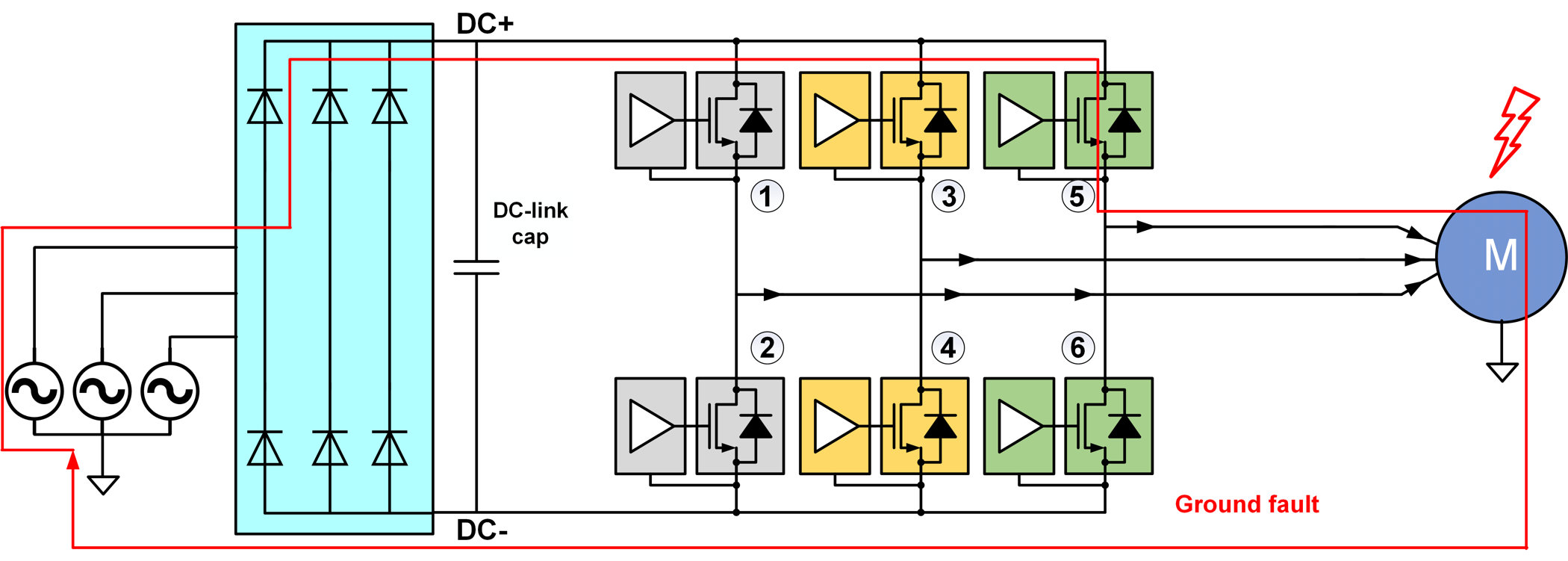

electric motor drives.As shown in Figure 3-2, a ground fault occurs when the motor cables, motor casing or motor windings are shorted to ground. Such shorts to ground can occur because of dielectric strength degradation in insulation caused by overstress conditions in temperature or voltage over an extended period of time. Old motors and cables are more vulnerable to ground-fault events, which can put human operators at risk for electric shocks. Thus, a ground fault requires detection and corrective actions such as rewinding or replacing the motor.

Figure 3-2 A ground fault in electric

motor drives.

Figure 3-2 A ground fault in electric

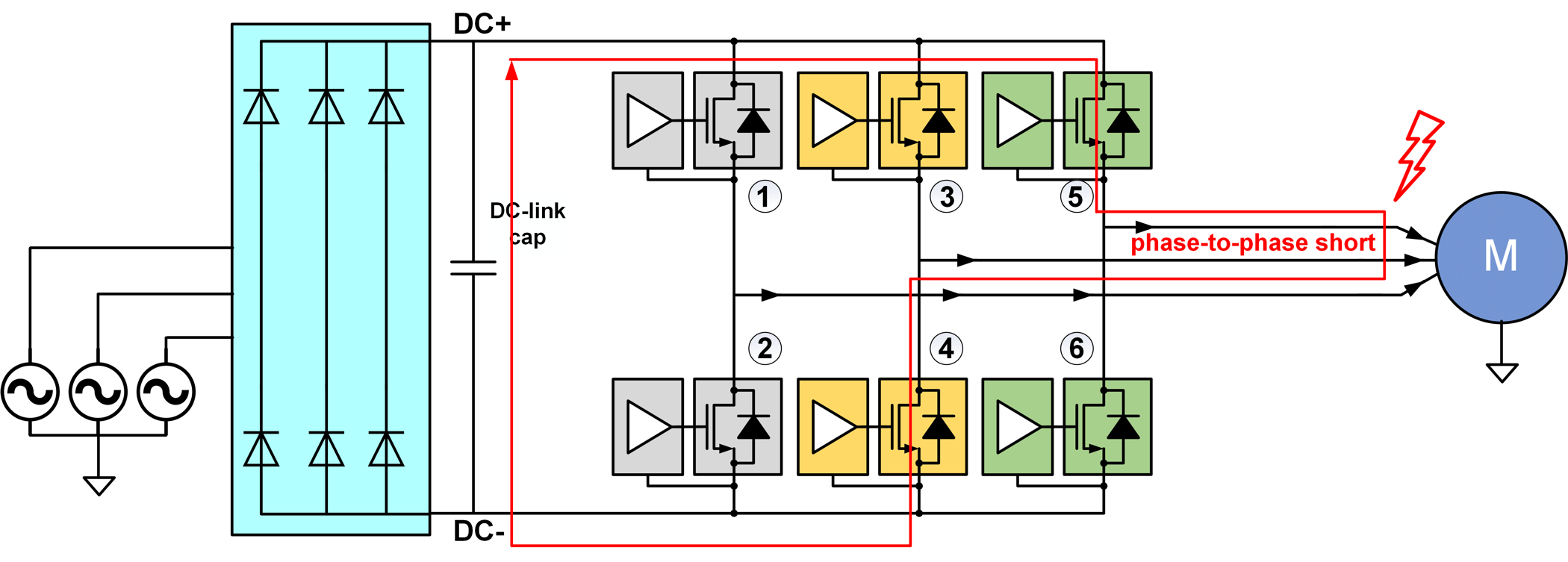

motor drives.As shown in Figure 3-3, a phase-to-phase short fault occurs when there is an insulation breakdown in between two windings of the two phases at the stator. These phase-to-phase shorts can occur because of dielectric strength degradation in insulation caused by overstress conditions in temperature or voltage over an extended period of time. This short results in a huge increase in stator current, resulting in potential damage to the IGBTs in the power stage. Old motors and cables are more vulnerable to phase-to-phase shorts. Like ground faults, phase-to-phase faults need detection and corrective actions such as rewinding or replacing the motor.

Figure 3-3 A phase-to-phase short in

electric motor drives.

Figure 3-3 A phase-to-phase short in

electric motor drives.Overvoltage occurs for several reasons – back-injection from the motor to the DC-link rail during breaking, poor regulation of AC power abnormal circuit loads, wiring errors and insulation failures. Overvoltage can result in voltage overstresses and excessive current that can damage DC-link capacitors and IGBTs, degrade the electrical insulation, and damage or reduce the lifetime of a motor-drive system. It is extremely important to limit the thermal energy through the IGBT by interrupting or reducing shoot-through, ground faults and phase-to-phase shorts, and avoiding transient overvoltage conditions.