SSZTA74 may 2017 DRV8833 , TPS62745

Wireless sensors are gaining popularity with the installation of more smart devices in homes and buildings. Battery-powered wireless devices enable very easy installation almost anywhere, but changing batteries frequently is not ideal from an ease-of-use or cost perspective.

For example, if you retrofit a commercial building with wireless sensor nodes to turn it into a smart building, that may entail the installation of several thousand wireless sensor nodes linked to various devices such as thermostats and smoke and fire detectors. Since it is impractical to run power cabling to every single node, batteries are a necessary power source. However, there is a significant labor cost when it comes time to change several thousand batteries in those wireless sensor nodes.

You can extend battery life in Internet of Things (IoT) sensing nodes by employing a duty-cycled approach. This is where the node powers up, records a measurement from the sensor, transmits that data wirelessly to a central hub or gateway and then turns itself off, either with a low-power mode or load switch. However, some applications such as star networks or certain Bluetooth® devices cannot stay in low-power mode for long if they have to be awake to transmit or pass along messages.

When smart devices require more power to operate motors (such as a smart lock or smart vent), battery life is more dependent on how the higher power is generated to run a motor, not the lower power needed to operate the radio. Texas Instruments has two separate reference designs that demonstrate a smart lock and smart vent application, respectively. The Smart Lock Reference Design Enabling 5+ Years Battery Life on 4x AA Batteries and Smart Damper Control with Pressure, Humidity and Temperature Reference Design for HVAC Diagnostics showcase TI’s high-efficiency DC/DC buck topology paired with the DRV8833 low-voltage motor driver. These reference designs achieve long battery life by choosing a more efficient power topology for the application – in this case a highly efficient buck converter, the TPS62745, and by extending the duty cycle of Bluetooth low energy connection events.

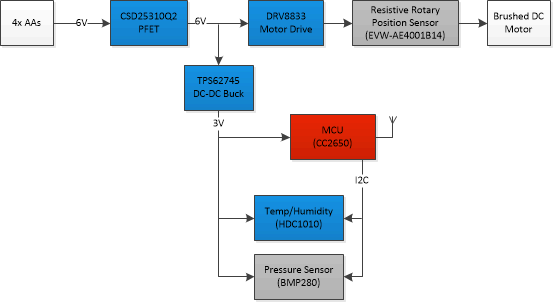

Figure 1 Smart Damper Control Reference

Design Block Diagram

Figure 1 Smart Damper Control Reference

Design Block DiagramThe DRV8833 is powered directly off the batteries, while the rest of the system operates from the buck’s output rail. During radio transmission, the buck is over 90% efficient at 9.1mA. The high-efficiency buck enables a longer battery life for the entire system compared to other topologies.

The smart damper control reference design enables you to alter the louver position of a vent, for example. The duct air pressure and temperature could be automated with algorithms, which in turn enable demand-controlled ventilation in a home. The pressure and temperature sensors enable heating, ventilation and air conditioning (HVAC) system component monitoring and can help with the identification of maintenance schedules. If a temperature or pressure differential between vents exists, the algorithm on board could hint that a filter needs to be changed and notify the home owner. The design can also act as a variable air volume controller in commercial applications.

As wireless smart sensing devices become battery-dependent, the power topology is more important to achieving long battery life in simple motor-control designs and “always-on” applications. Check out the additional resources to see how TI can help you optimize battery life in your application.

Additional Resources

- Watch our training series to learn more about optimizing wireless sensor nodes.

- See these other TI reference designs for “always-on” wireless sensing applications: