SSZTAA4 march 2018 TMS320F28377D

One of the main concerns with electric vehicles (EVs) is their ability to travel long distances without running out of “gas” – in this case, charge. There are two main factors associated with this concern: battery capacity and where to charge the EV.

You might be surprised to learn that this isn’t a new problem. EVs have been around in some form or another since the 1800s, and the same problems we face today are similar in nature to those faced by our ancestors.

In fact, in the early 1900s, one quarter of all automobiles produced in the U.S. were EVs. One of the main reasons EVs fell out of favor was the relative ease with which gasoline could be distributed and supplied vs. electricity. It would take another 60 years before environmental reasons led to a renewed discussion of the need for EVs.

EVs have now become a viable alternative to traditional gas-powered vehicles. There are a number of reasons for this – advances in battery capacity, higher efficiency motors, personal awareness of pollution, etc. There is still a challenge, however, related to public charging availability, as well as how quickly those chargers can “fill up the tank” of an EV. Charging stations, including DC fast charging stations, will need to become as commonplace as gas stations to satisfy market needs and continue to make EVs more viable.

There are hurdles to making this a reality. One such challenge is compatibility across all EV chargers to all EVs. As a corollary, I doubt there is even a question when pulling up to a gas station whether or not the nozzle will fit, or if the gas will be the right kind for the vehicle. These aren’t yet assumptions at EV charging stations.

Understanding the importance of this, TI has joined the CharIN e.V. consortium, whose mission is to make a standard for charging battery-powered EVs. A common platform across the industry will enable consumers to be confident that if they have access to a charging station, it will work with their vehicle.

Another important step is to enable more Level III chargers to help reduce charge times as batteries get larger and larger. For that, TI has several reference designs using C2000™ microcontrollers (MCUs) to help get manufacturers started.

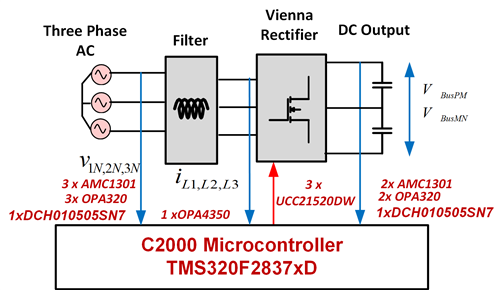

Leveraging our decades of experience in high-voltage rectifiers used in the network server space, TI created designs specifically for the EV charger market. First is the Vienna Rectifier-Based Three Phase Power Factor Correction Reference Design Using C2000 MCU. Built on our latest Delfino™ TMS320F28377D dual-core C2000 MCU, it achieves 98% peak efficiency as well as being supported in our powerSUITE software library. This reference design handles the AC/DC component of a Level III charger.

The Two Phase Interleaved LLC Resonant Converter Reference Design Using C2000 MCUs is a DC/DC solution that takes the DC output from the Vienna rectifier and converts it to a DC bus voltage usable by an EV battery. This design also leverages the TMS320F28377D MCU and supports current sharing, as well as synchronous rectification and phase shedding.

For EVs to reach their true potential as the choice of transportation for the masses, increasing the EV supply equipment (EVSE) footprint will be vital. Compatibility and fast charging solutions are two key aspects. With solutions from Texas Instruments, we believe that designers can overcome the challenges.

Additional Resources

- Read more about Level III chargers in the blog post, “Pile on to a charger – my EV needs power.”

- “Electric vehicle drives around the world on a single gallon of gas.”

- “Communicate with electric vehicle charging stations – integrate Wi-Fi.”

- Accelerate your knowledge of electric vehicle charging stations – take our training.

- Read out blog series on motors in electric vehicles: