SSZTBB7 May 2016 LDC0851

Switching and latching applications that involve detecting the presence of a moving object can be complicated to design and plagued by reliability problems. Examples include implementing tamper detection for opening and closing doors, or measuring the rotational speed of a gear regularly exposed to dust or oil that could block the sensor and cause failures.

Additional challenges exist depending on the specific technology used for the switching application, including:

- An inaccurate switching threshold due to the requirement of an additional component such as a magnet or magnetized material, which is often not very accurate due to variations between parts and often requires calibration in production.

- Temperature variation and component aging, which affects the accuracy and repeatability of the switching threshold.

The introduction of TI’s LDC0851 differential inductive switch enables a new approach that offers a temperature-stable switching threshold accurate to 1% of the coil diameter, eliminating the need for production calibration.

LDC0851 Differential Inductive Switching Theory

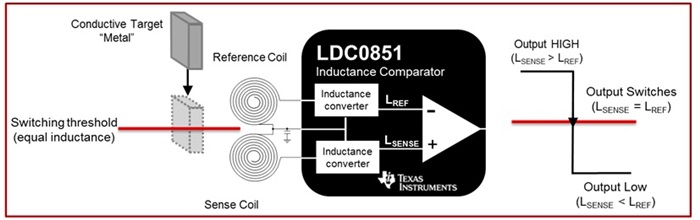

The LDC0851, as shown in Figure 1, uses inductive sensing to perform a simple inductance comparison between two matched printed circuit board (PCB) coils. The output switches high or low depending on which coil has less inductance.

Figure 1 LDC0851 Differential Inductive Switch Functional Diagram

Figure 1 LDC0851 Differential Inductive Switch Functional DiagramApplication Examples

This new approach to switching applications offers benefits for two main categories of applications:

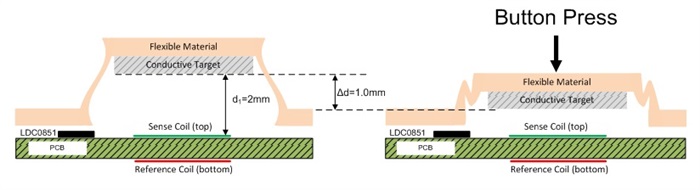

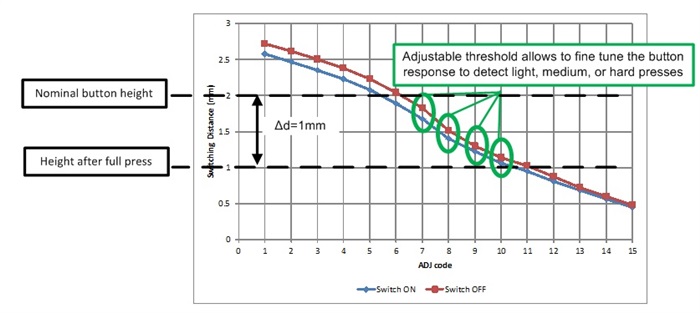

- Proximity-detection applications that need a contactless and repeatable switching threshold, such as simple buttons, door open/close detection mechanisms and industrial proximity switches. Figure 2 shows a proximity-detection application in which an LDC0851 senses the position of a snap-dome button without electrical contact. Figure 3 shows that the adjustable threshold allows for easy prototyping and fine-tuning the response to detect the button response.

Figure 2 Proximity Detection for an Example Button Application

Figure 2 Proximity Detection for an Example Button Application Figure 3 Adjustable Threshold to Fine Tune Button Response

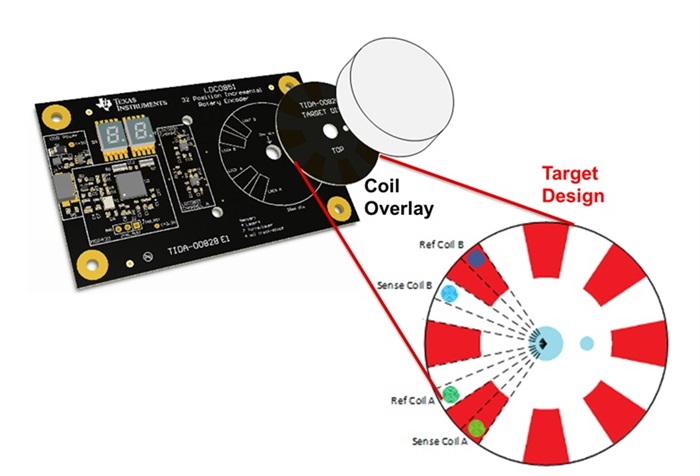

Figure 3 Adjustable Threshold to Fine Tune Button Response- Event-counting applications that need to work well in dirty and harsh environments, such as flow meters, gear speed measurement devices and rotary encoders benefit from robust nature of inductive switching. The TI Designs Inductive Sensing 32-Position Encoder Knob Reference Design Using the LDC0851 shown in Figure 4 implements a 32-position encoder knob commonly found in automotive infotainment or appliance interfaces such as cooktops and volume knobs.

Figure 4 LDC0851-Based Encoder-knob Reference Design

Figure 4 LDC0851-Based Encoder-knob Reference DesignPrototyping Tools and Resources

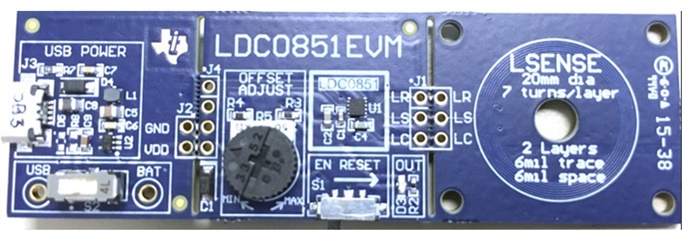

A simple coin-cell battery-powered evaluation module (EVM), shown in Figure 5, demonstrates close-range proximity sensing as well as simple on/off metal-button detection. This EVM includes a perforation that enables you to replace the default sensor with a custom sensor.

If you’re interested in learning more about the new inductive switch, the WEBENCH® coil design tool can help simplify the design of stacked coils for the LDC0851. In the next post, we will go through a design example and show you how to use the new tool.

Additional Resources

- View the LDC0851 data sheet and LDC0851 quick-start guide.

- Download the LDC tools spreadsheet, which includes a dedicated tab to configure an LDC0851.

- Read other blogs about inductive sensing.

- Which type of sensor do you think is most useful? I’m voting “inductive” in EDN’s reader poll.