SSZTCE5 July 2015 UCC24630

Ever wonder how the power level of chargers keeps increasing (to take advantage of USB Type-C standards, for example), but are still small in size? There is only so much power you can dissipate inside a sealed plastic box before the charger doubles as a hand warmer and becomes unreliable. You must achieve higher efficiency.

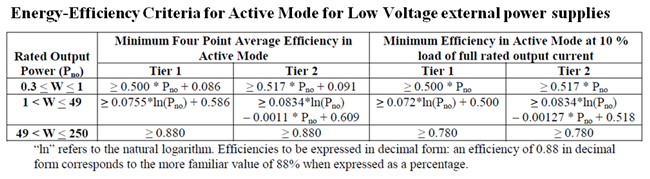

Beyond this need for high efficiency, more strict standards will make meeting efficiency requirements more challenging. The European Code of Conduct (COC) has a new standard that will take effect in January 2016. As shown in Table 1, a 15W low-voltage power supply must achieve better than 81.8% average efficiency and better than 72.5% efficiency at 10% rated power.

|

In a charger, the component that dissipates the most power is usually the output rectifier diode. One way to increase the efficiency by 5% or more in a 5V phone charger or by 2% or more in a 19.2V notebook or ultrabook adapter is to replace the output diode with a synchronous rectifier (SR) MOSFET and controller.

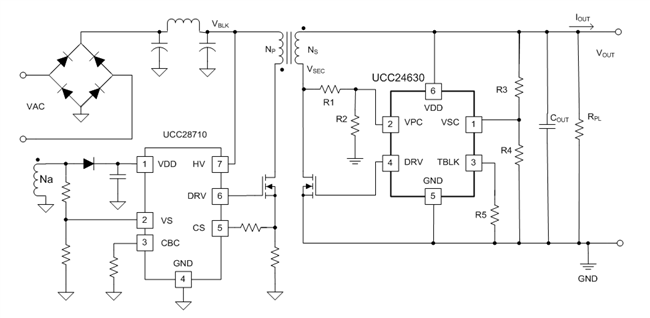

SR controllers can increase the efficiency in a charger. TI recently released the UCC24630 SR controller with ultra-low standby current. The UCC24630 SR controller can maximize the efficiency increase and have very little impact on standby power. Figure 1 shows a typical application of the UCC24630 chip.

Figure 1 Typical Flyback Converter

Application Using the UCC24630

Figure 1 Typical Flyback Converter

Application Using the UCC24630Synchronous rectification provides a noticeable improvement in efficiency by replacing the diode forward-voltage drop with an IR drop. To get the most benefit from the controller, you must drive the MOSFET with optimum drive levels and timing. The majority of SR controllers today work on a principle of VDS level sensing to determine when to turn the SR MOSFET on and off. Two types of popular VDS-sensing controllers compromise either the SR conduction time or the voltage across the MOSFET drain to source during secondary current conduction. The first type, fixed threshold sensing, results in early turn off of the MOSFET, especially with a lower RDSON MOSFET intended to improve conduction loss. The second type, proportional drive, improves conduction time but sacrifices higher voltage drop across the MOSFET with variable gate-drive voltage. Both are sensitive to the MOSFET RDSON.

The UCC24630’s driver timing is based on the principle of volt-second balance, which results in accurate timing of the SR at full drive voltage. The turn-off timing is not sensitive to MOSFET RDSON. You realize the benefits of using lower RDSON MOSFETs, thus reducing conduction losses in the SR MOSFET. Using an example of a 5V 15W charger and a SR MOSFET RDSON of 3.5mΩ, the UCC24630 SR MOSFET loss is ~10% less than fixed-threshold VDS sensing and 35% less than proportional-drive VDS-sensing SR controllers.

For those designs that have strict no-load power-consumption requirements, automatic detection of low-power operating mode and a low standby-mode current of 110µA, there is minimal load impact: <1mW on a typical 5V charger. Many SR controllers consume up to 1-2mA of current, which can be a significant amount for a standby power budget. In 19.4V notebook or ultrabook adapters, this difference of 1-2mA to 110µA translates to 17 to 34mW of added power for the SR controller.

With higher-power adapters, many designs operate the flyback converter in continuous conduction mode (CCM) to improve efficiency. The CCM operating mode is challenging for SR controllers because the secondary current does not go to zero before the primary-side switch turns on. The wrong timing could result in cross-conduction of the primary- and secondary-side switches. The UCC24630 includes CCM dead-time control to ensure that the SR MOSFET is turned off before the primary turn on, eliminating cross-conduction.

New standards have made achieving efficiency standards in chargers more difficult, but utilizing SR controllers, such as the UCC24630, can make it possible to meet those standards. How have the increasing requirements for high efficiency changed the way you design?

Additional Resources:

- To jump start your design, download these TI Designs reference designs: