SNOS965J June 2001 – December 2015 LM2611

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2 Typical Application

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DBV|5

Thermal pad, mechanical data (Package|Pins)

Orderable Information

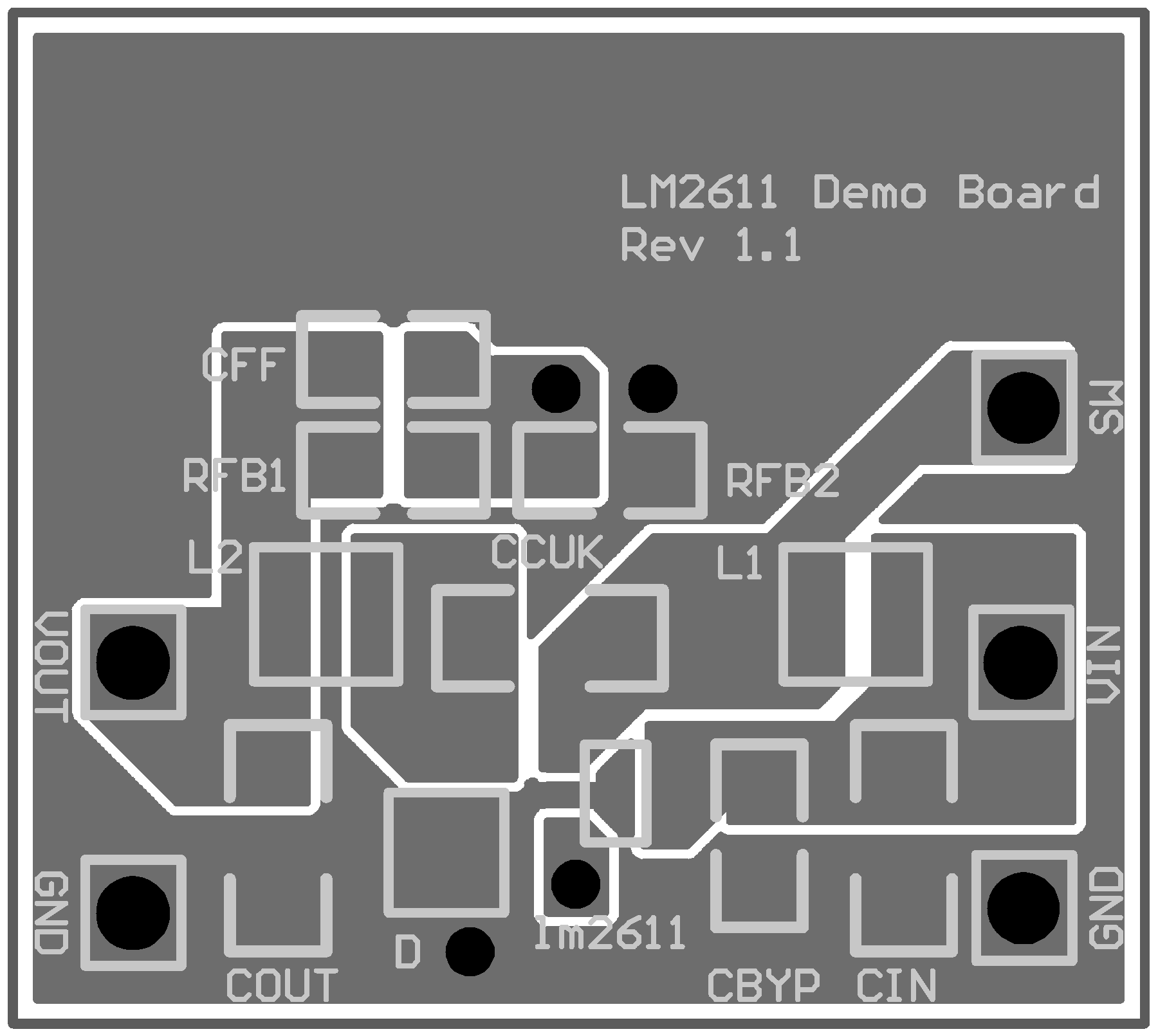

10 Layout

10.1 Layout Guidelines

- Connection between L1 and SW pin should be kept as short as possible to minimize inductance

- Connection between CCUK and SW should also be kept short

- The feedback resistor should be placed close to the NFB pin to minimize the path of the higher impedance feedback node

- The feedback trace leading from Vout to the output to the feedback resistors should not pass under the switch node between L1 and CCUK and the switch node between CCUK, L2 and D

- The feedback trace leading from Vout to the output to the feedback resistors should not pass under the inductors L1 and L2

- A bypass capacitor CBYP of 0.1 µF should be placed close to VIN and GND pin

10.2 Layout Example

Figure 36. Example Layout Top

Figure 36. Example Layout Top

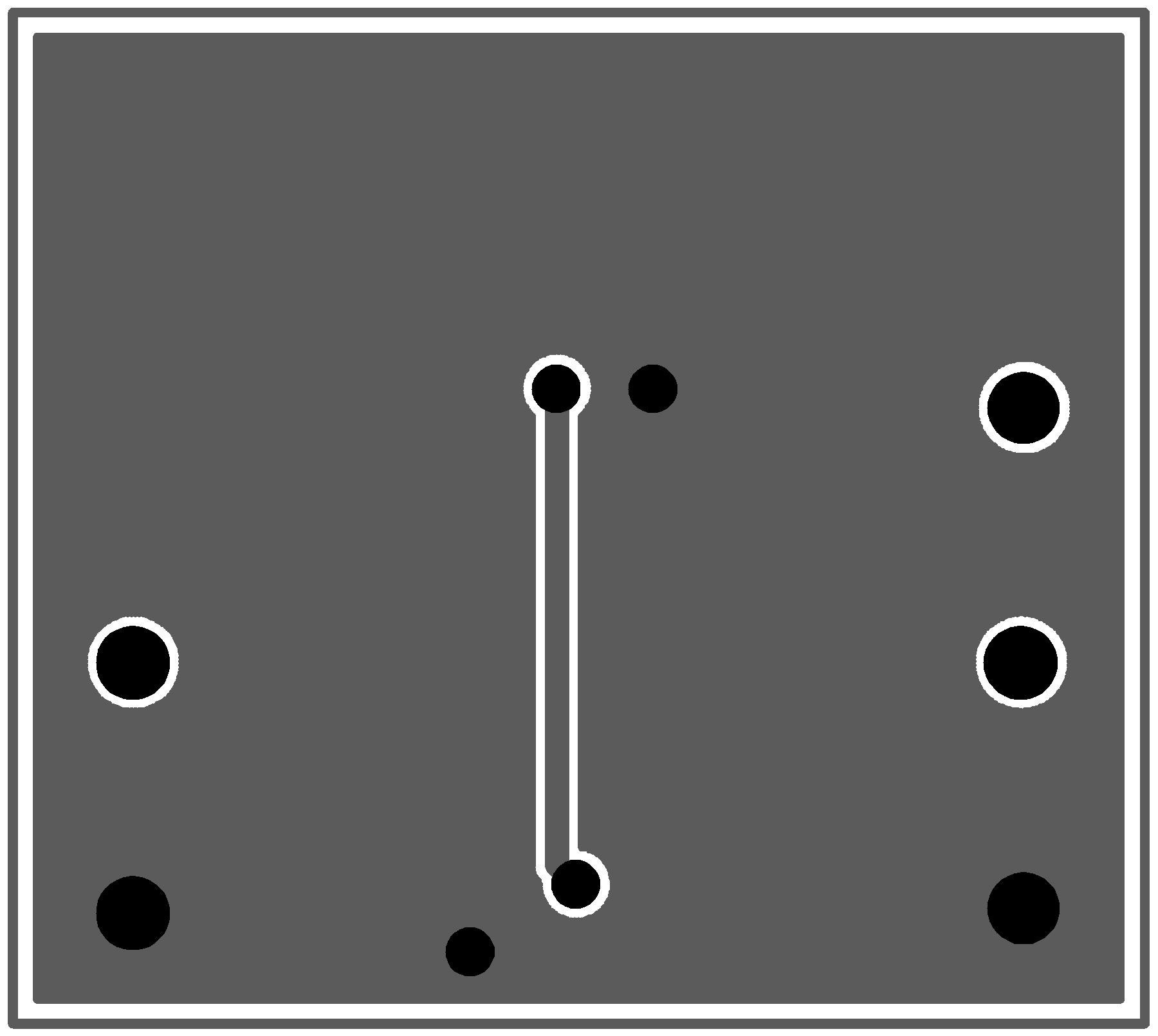

Figure 37. Example Layout Bottom

Figure 37. Example Layout Bottom