SNVS136L September 1998 – June 2016 LM2672

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Description (continued)

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics - 3.3 V

- 7.6 Electrical Characteristics - 5 V

- 7.7 Electrical Characteristics - 12 V

- 7.8 Electrical Characteristics - Adjustable

- 7.9 Electrical Characteristics - All Output Voltage Versions

- 7.10 Typical Characteristics

- 7.11 Typical Characteristics - Fixed Output Voltage Versions

- 8 Parameter Measurement Information

- 9 Detailed Description

-

10Application and Implementation

- 10.1 Application Information

- 10.2

Typical Applications

- 10.2.1 Typical Application for Fixed Output Voltage Versions

- 10.2.2 Typical Application for Adjustable Output Voltage Versions

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

Orderable Information

10 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

10.1 Application Information

The LM2672 is a step-down DC-DC regulator. It is typically used to convert a higher DC voltage to a lower DC voltage with a maximum output current of 1 A. The following design procedure can be used to select components for the LM2672.

When the output voltage is greater than approximately 6 V, and the duty cycle at minimum input voltage is greater than approximately 50%, the designer must exercise caution in selection of the output filter components. When an application designed to these specific operating conditions is subjected to a current limit fault condition, it may be possible to observe a large hysteresis in the current limit. This can affect the output voltage of the device until the load current is reduced sufficiently to allow the current limit protection circuit to reset itself.

Under current limiting conditions, the LM267x is designed to respond in the following manner:

- At the moment when the inductor current reaches the current limit threshold, the ON-pulse is immediately terminated. This happens for any application condition.

- However, the current limit block is also designed to momentarily reduce the duty cycle to below 50% to avoid subharmonic oscillations, which could cause the inductor to saturate.

- Thereafter, once the inductor current falls below the current limit threshold, there is a small relaxation time during which the duty cycle progressively rises back above 50% to the value required to achieve regulation.

10.2 Typical Applications

10.2.1 Typical Application for Fixed Output Voltage Versions

COUT = 47-μF, 25-V Tantalum, Sprague 595D Series

D1 = 3.3-A, 50-V Schottky Rectifier, IR 30WQ05F

L1 = 68-μH Sumida #RCR110D-680L

CB = 0.01-μF, 50-V Ceramic

10.2.1.1 Design Requirements

Table 1 lists the design requirements for the fixed output voltage application.

Table 1. Fixed Output Voltage Application Parameters

| PARAMETER | VALUE |

|---|---|

| Regulated output voltage (3.3 V, 5 V, or 12 V), VOUT | 5 V |

| Maximum DC input voltage, VIN(max) | 12 V |

| Maximum load current, ILOAD(max) | 1 A |

10.2.1.2 Detailed Design Procedure

10.2.1.2.1 Inductor Selection (L1)

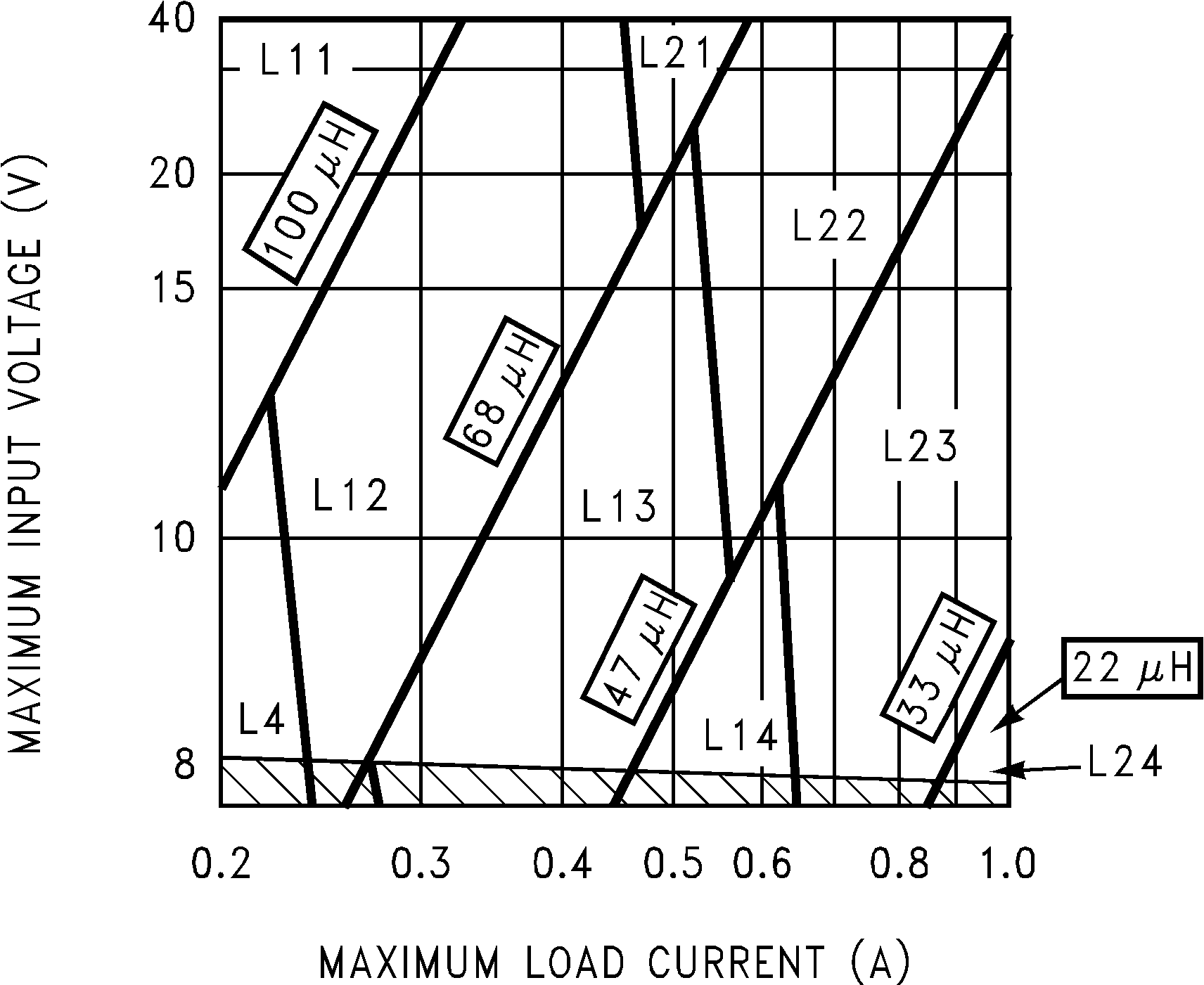

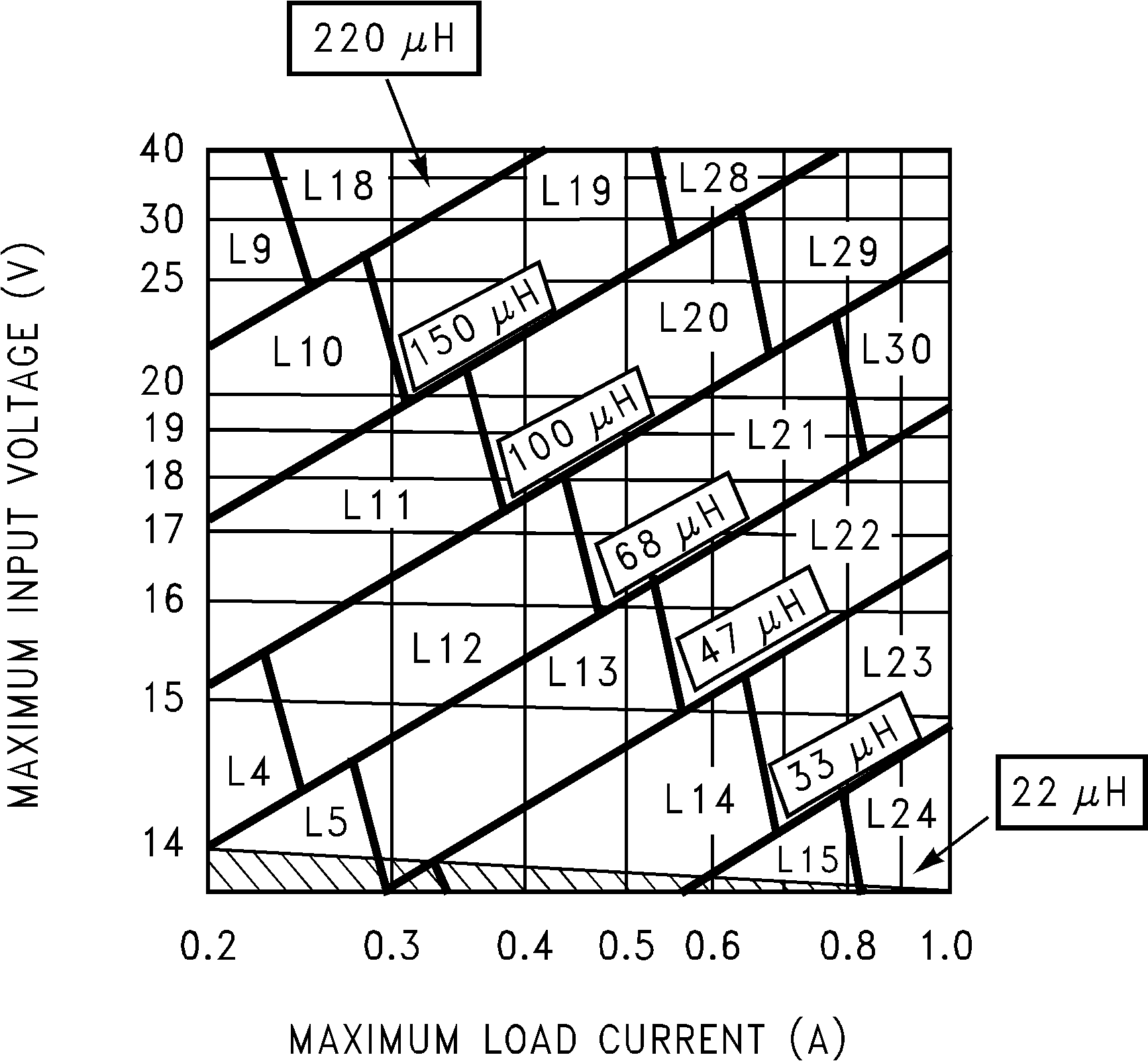

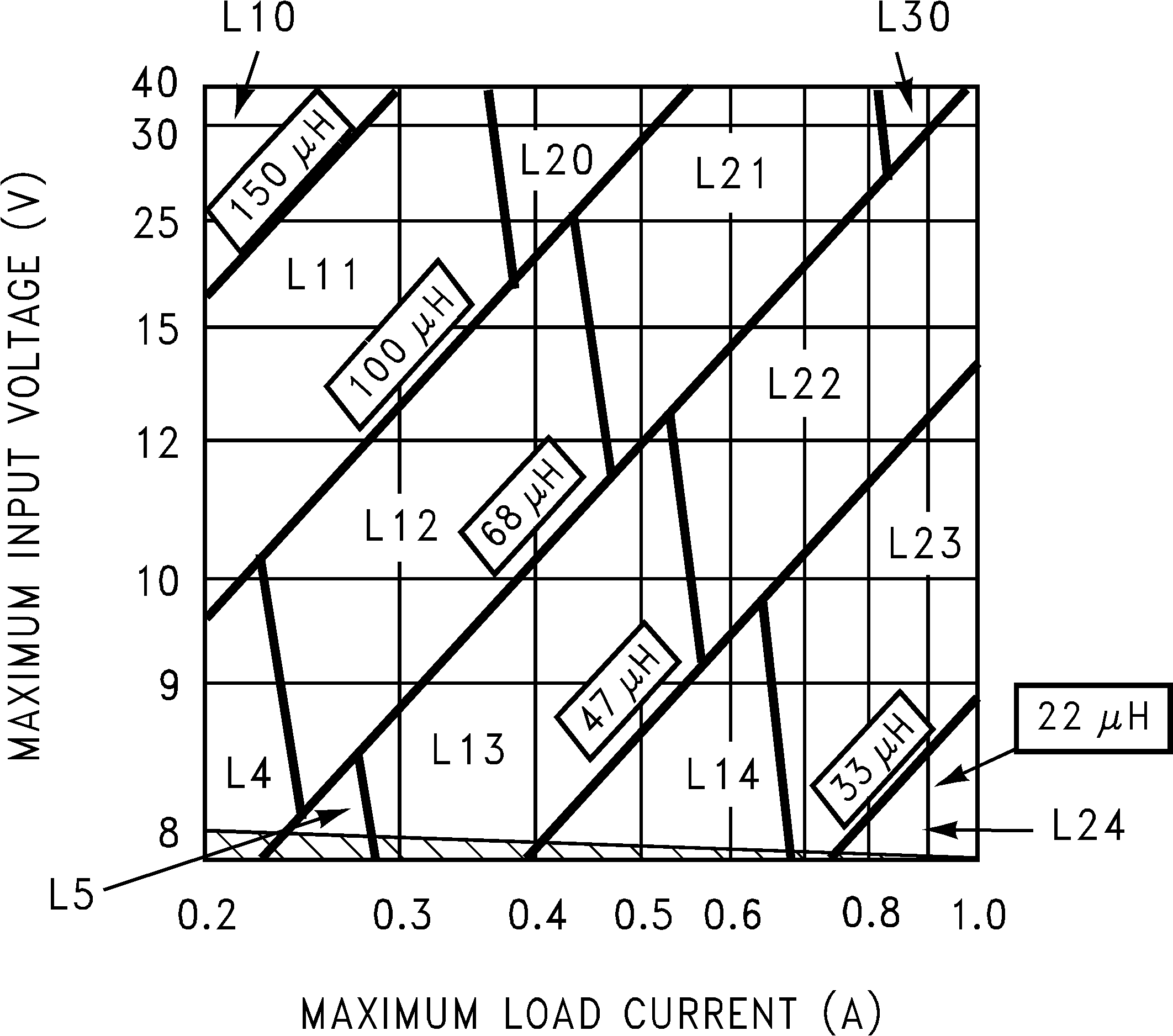

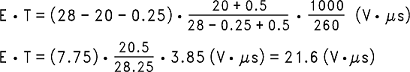

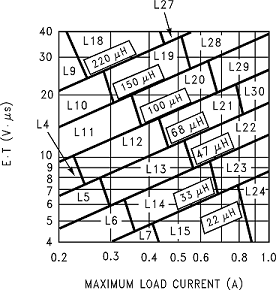

First, select the correct inductor value selection guide from Figure 23, Figure 24, or Figure 25 (output voltages of 3.3-V, 5-V, or 12-V respectively). For all other voltages, see the design procedure for the adjustable version. Use the inductor selection guide for the 5-V version shown in Figure 24.

From the inductor value selection guide, identify the inductance region intersected by the maximum input voltage line and the maximum load current line. Each region is identified by an inductance value and an inductor code (LXX). From the inductor value selection guide shown in Figure 24, the inductance region intersected by the 12 V horizontal line and the 1 A vertical line is 33 μH, and the inductor code is L23.

Select an appropriate inductor from the four manufacturer's part numbers listed in Table 2. Each manufacturer makes a different style of inductor to allow flexibility in meeting various design requirements. The inductance value required is 33 μH. From Table 2, go to the L23 line and choose an inductor part number from any of the four manufacturers shown. In most instances, both through hole and surface mount inductors are available.

Table 2. Inductor Manufacturers' Part Numbers

| IND. REF. DESG. |

INDUCTANCE (μH) |

CURRENT (A) |

SCHOTT | RENCO | PULSE ENGINEERING | COILCRAFT | |||

|---|---|---|---|---|---|---|---|---|---|

| THROUGH HOLE | SURFACE MOUNT | THROUGH HOLE | SURFACE MOUNT | THROUGH HOLE | SURFACE MOUNT | SURFACE MOUNT | |||

| L4 | 68 | 0.32 | 67143940 | 67144310 | RL-1284-68-43 | RL1500-68 | PE-53804 | PE-53804-S | DO1608-683 |

| L5 | 47 | 0.37 | 67148310 | 67148420 | RL-1284-47-43 | RL1500-47 | PE-53805 | PE-53805-S | DO1608-473 |

| L6 | 33 | 0.44 | 67148320 | 67148430 | RL-1284-33-43 | RL1500-33 | PE-53806 | PE-53806-S | DO1608-333 |

| L7 | 22 | 0.52 | 67148330 | 67148440 | RL-1284-22-43 | RL1500-22 | PE-53807 | PE-53807-S | DO1608-223 |

| L9 | 220 | 0.32 | 67143960 | 67144330 | RL-5470-3 | RL1500-220 | PE-53809 | PE-53809-S | DO3308-224 |

| L10 | 150 | 0.39 | 67143970 | 67144340 | RL-5470-4 | RL1500-150 | PE-53810 | PE-53810-S | DO3308-154 |

| L11 | 100 | 0.48 | 67143980 | 67144350 | RL-5470-5 | RL1500-100 | PE-53811 | PE-53811-S | DO3308-104 |

| L12 | 68 | 0.58 | 67143990 | 67144360 | RL-5470-6 | RL1500-68 | PE-53812 | PE-53812-S | DO3308-683 |

| L13 | 47 | 0.70 | 67144000 | 67144380 | RL-5470-7 | RL1500-47 | PE-53813 | PE-53813-S | DO3308-473 |

| L14 | 33 | 0.83 | 67148340 | 67148450 | RL-1284-33-43 | RL1500-33 | PE-53814 | PE-53814-S | DO3308-333 |

| L15 | 22 | 0.99 | 67148350 | 67148460 | RL-1284-22-43 | RL1500-22 | PE-53815 | PE-53815-S | DO3308-223 |

| L18 | 220 | 0.55 | 67144040 | 67144420 | RL-5471-2 | RL1500-220 | PE-53818 | PE-53818-S | DO3316-224 |

| L19 | 150 | 0.66 | 67144050 | 67144430 | RL-5471-3 | RL1500-150 | PE-53819 | PE-53819-S | DO3316-154 |

| L20 | 100 | 0.82 | 67144060 | 67144440 | RL-5471-4 | RL1500-100 | PE-53820 | PE-53820-S | DO3316-104 |

| L21 | 68 | 0.99 | 67144070 | 67144450 | RL-5471-5 | RL1500-68 | PE-53821 | PE-53821-S | DO3316-683 |

| L22 | 47 | 1.17 | 67144080 | 67144460 | RL-5471-6 | — | PE-53822 | PE-53822-S | DO3316-473 |

| L23 | 33 | 1.4 | 67144090 | 67144470 | RL-5471-7 | — | PE-53823 | PE-53823-S | DO3316-333 |

| L24 | 22 | 1.7 | 67148370 | 67148480 | RL-1283-22-43 | — | PE-53824 | PE-53824-S | DO3316-223 |

| L27 | 220 | 1 | 67144110 | 67144490 | RL-5471-2 | — | PE-53827 | PE-53827-S | DO5022P-224 |

| L28 | 150 | 1.2 | 67144120 | 67144500 | RL-5471-3 | — | PE-53828 | PE-53828-S | DO5022P-154 |

| L29 | 100 | 1.47 | 67144130 | 67144510 | RL-5471-4 | — | PE-53829 | PE-53829-S | DO5022P-104 |

| L30 | 68 | 1.78 | 67144140 | 67144520 | RL-5471-5 | — | PE-53830 | PE-53830-S | DO5022P-683 |

10.2.1.2.2 Output Capacitor Selection (COUT)

Select an output capacitor from the output capacitor table in Table 3. Using the output voltage and the inductance value found in the inductor selection guide, step 1, locate the appropriate capacitor value and voltage rating. Use the 5-V section in Table 3. Choose a capacitor value and voltage rating from the line that contains the inductance value of 33 μH. The capacitance and voltage rating values corresponding to the 33 μH.

The capacitor list contains through-hole electrolytic capacitors from four different capacitor manufacturers and surface mount tantalum capacitors from two different capacitor manufacturers.

Surface mount:

- 68-μF, 10-V Sprague 594D series

- 100-μF, 10-V AVX TPS series

Through hole:

- 68-μF, 10-V Sanyo OS-CON SA series

- 220-μF, 35-V Sanyo MV-GX series

- 220-μF, 35-V Nichicon PL series

- 220-μF, 35-V Panasonic HFQ series

Table 3. Output Capacitor Table

| OUTPUT VOLTAGE (V) |

INDUCTANCE (μH) |

OUTPUT CAPACITOR | |||||

|---|---|---|---|---|---|---|---|

| SURFACE MOUNT | THROUGH HOLE | ||||||

| SPRAGUE 594D SERIES (μF/V) |

AVX TPS SERIES (μF/V) |

SANYO OS-CON SA SERIES (μF/V) |

SANYO MV-GX SERIES (μF/V) |

NICHICON PL SERIES (μF/V) |

PANASONIC HFQ SERIES (μF/V) |

||

| 3.3 | 22 | 120/6.3 | 100/10 | 100/10 | 330/35 | 330/35 | 330/35 |

| 33 | 120/6.3 | 100/10 | 68/10 | 220/35 | 220/35 | 220/35 | |

| 47 | 68/10 | 100/10 | 68/10 | 150/35 | 150/35 | 150/35 | |

| 68 | 120/6.3 | 100/10 | 100/10 | 120/35 | 120/35 | 120/35 | |

| 100 | 120/6.3 | 100/10 | 100/10 | 120/35 | 120/35 | 120/35 | |

| 150 | 120/6.3 | 100/10 | 100/10 | 120/35 | 120/35 | 120/35 | |

| 5 | 22 | 100/16 | 100/10 | 100/10 | 330/35 | 330/35 | 330/35 |

| 33 | 68/10 | 10010 | 68/10 | 220/35 | 220/35 | 220/35 | |

| 47 | 68/10 | 100/10 | 68/10 | 150/35 | 150/35 | 150/35 | |

| 68 | 100/16 | 100/10 | 100/10 | 120/35 | 120/35 | 120/35 | |

| 100 | 100/16 | 100/10 | 100/10 | 120/35 | 120/35 | 120/35 | |

| 150 | 100/16 | 100/10 | 100/10 | 120/35 | 120/35 | 120/35 | |

| 12 | 22 | 120/20 | (2×) 68/20 | 68/20 | 330/35 | 330/35 | 330/35 |

| 33 | 68/25 | 68/20 | 68/20 | 220/35 | 220/35 | 220/35 | |

| 47 | 47/20 | 68/20 | 47/20 | 150/35 | 150/35 | 150/35 | |

| 68 | 47/20 | 68/20 | 47/20 | 120/35 | 120/35 | 120/35 | |

| 100 | 47/20 | 68/20 | 47/20 | 120/35 | 120/35 | 120/35 | |

| 150 | 47/20 | 68/20 | 47/20 | 120/35 | 120/35 | 120/35 | |

| 220 | 47/20 | 68/20 | 47/20 | 120/35 | 120/35 | 120/35 | |

10.2.1.2.3 Catch Diode Selection (D1)

In normal operation, the average current of the catch diode is the load current times the catch diode duty cycle, 1-D (D is the switch duty cycle, which is approximately the output voltage divided by the input voltage). The largest value of the catch diode average current occurs at the maximum load current and maximum input voltage (minimum D). For normal operation, the catch diode current rating must be at least 1.3 times greater than its maximum average current. However, if the power supply design must withstand a continuous output short, the diode must have a current rating equal to the maximum current limit of the LM2672. The most stressful condition for this diode is a shorted output condition. Refer to the table shown in Table 4. In this example, a 1-A, 20-V Schottky diode provides the best performance. If the circuit must withstand a continuous shorted output, a higher current Schottky diode is recommended.

The reverse voltage rating of the diode must be at least 1.25 times the maximum input voltage. Because of their fast switching speed and low forward voltage drop, Schottky diodes provide the best performance and efficiency. This Schottky diode must be placed close to the LM2672 using short leads and short printed circuit traces.

Table 4. Schottky Diode Selection Table

| VR | 1-A DIODES | 3-A DIODES | ||

|---|---|---|---|---|

| SURFACE MOUNT | THROUGH HOLE | SURFACE MOUNT | THROUGH HOLE | |

| 20 V | SK12 | 1N5817 | SK32 | 1N5820 |

| B120 | SR102 | — | SR302 | |

| 30 V | SK13 | 1N5818 | SK33 | 1N5821 |

| B130 | 11DQ03 | 30WQ03F | 31DQ03 | |

| MBRS130 | SR103 | — | — | |

| 40 V | SK14 | 1N5819 | SK34 | 1N5822 |

| B140 | 11DQ04 | 30BQ040 | MBR340 | |

| MBRS140 | SR104 | 30WQ04F | 31DQ04 | |

| 10BQ040 | — | MBRS340 | SR304 | |

| 10MQ040 | — | MBRD340 | — | |

| 15MQ040 | — | — | — | |

| 50 V | SK15 | MBR150 | SK35 | MBR350 |

| B150 | 11DQ05 | 30WQ05F | 31DQ05 | |

| 10BQ050 | SR105 | — | SR305 | |

10.2.1.2.4 Input Capacitor (CIN)

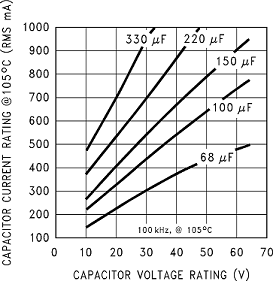

A low ESR aluminum or tantalum bypass capacitor is required between the input pin and ground to prevent large voltage transients from appearing at the input. This capacitor must be placed close to the IC using short leads. In addition, the RMS current rating of the input capacitor must be selected to be at least ½ the DC load current. The capacitor manufacturer data sheet must be checked to assure that this current rating is not exceeded. Figure 21 shows typical RMS current ratings for several different aluminum electrolytic capacitor values. A parallel connection of two or more capacitors may be required to increase the total minimum RMS current rating to suit the application requirements.

Figure 21. RMS Current Ratings for Low ESR Electrolytic Capacitors (Typical)

Figure 21. RMS Current Ratings for Low ESR Electrolytic Capacitors (Typical)

For an aluminum electrolytic capacitor, the voltage rating must be at least 1.25 times the maximum input voltage. Caution must be exercised if solid tantalum capacitors are used. The tantalum capacitor voltage rating must be twice the maximum input voltage. The tables in Table 5 show the recommended application voltage for AVX TPS and Sprague 594D tantalum capacitors. It is also recommended that they be surge current tested by the manufacturer. The TPS series available from AVX, and the 593D and 594D series from Sprague are all surge current tested. Another approach to minimize the surge current stresses on the input capacitor is to add a small inductor in series with the input supply line.

Table 5. Recommended Application Voltage for AVX TPS and Sprague 594D Tantalum Chip Capacitors Derated for 85°C

| RECOMMENDED APPLICATION VOLTAGE | VOLTAGE RATING |

|---|---|

| 3.3 | 6.3 |

| 5 | 10 |

| 10 | 20 |

| 12 | 25 |

| 15 | 35 |

Use caution when using ceramic capacitors for input bypassing, because it may cause severe ringing at the VIN pin.

The important parameters for the input capacitor are the input voltage rating and the RMS current rating. With a maximum input voltage of 12 V, an aluminum electrolytic capacitor with a voltage rating greater than 15 V (1.25 × VIN) is required. The next higher capacitor voltage rating is 16 V.

The RMS current rating requirement for the input capacitor in a buck regulator is approximately ½ the DC load current. In this example, with a 1-A load, a capacitor with a RMS current rating of at least 500 mA is required. The curves shown in Figure 21 can be used to select an appropriate input capacitor. From the curves, locate the 16-V line and note which capacitor values have RMS current ratings greater than 500 mA.

For a through hole design, a 330-μF, 16-V electrolytic capacitor (Panasonic HFQ series, Nichicon PL, Sanyo MV-GX series or equivalent) would be adequate. Other types or other manufacturers' capacitors can be used provided the RMS ripple current ratings are adequate. Additionally, for a complete surface mount design, electrolytic capacitors such as the Sanyo CV-C or CV-BS and the Nichicon WF or UR and the NIC Components NACZ series could be considered.

For surface mount designs, solid tantalum capacitors can be used, but caution must be exercised with regard to the capacitor surge current rating and voltage rating. In this example, checking Table 5, and the Sprague 594D series data sheet, a Sprague 594D 15-μF, 25-V capacitor is adequate.

10.2.1.2.5 Boost Capacitor (CB)

This capacitor develops the necessary voltage to turn the switch gate on fully. All applications must use a 0.01-μF, 50-V ceramic capacitor.

10.2.1.2.6 Soft-Start Capacitor (CSS, Optional)

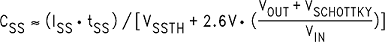

This capacitor controls the rate at which the device starts up. The formula for the soft-start capacitor CSS is calculated with Equation 1.

where

- ISS = Soft-start current (4.5 µA, typical)

- tSS = Soft-start time (selected)

- VSSTH = Soft-start threshold voltage (0.63 V, typical)

- VOUT = Output voltage (selected)

- VSCHOTTKY = Schottky diode voltage drop (0.4 V, typical)

- VIN = Input voltage (selected)

If this feature is not desired, leave this pin open. With certain soft-start capacitor values and operating conditions, the LM2672 can exhibit an overshoot on the output voltage during turn on. Especially when starting up into no load or low load, the soft-start function may not be effective in preventing a larger voltage overshoot on the output. With larger loads or lower input voltages during startup this effect is minimized. In particular, avoid using soft-start capacitors between 0.033 µF and 1 µF.

For this application, selecting a start-up time of 10 ms and using the formula for CSS results in a value of Equation 2.

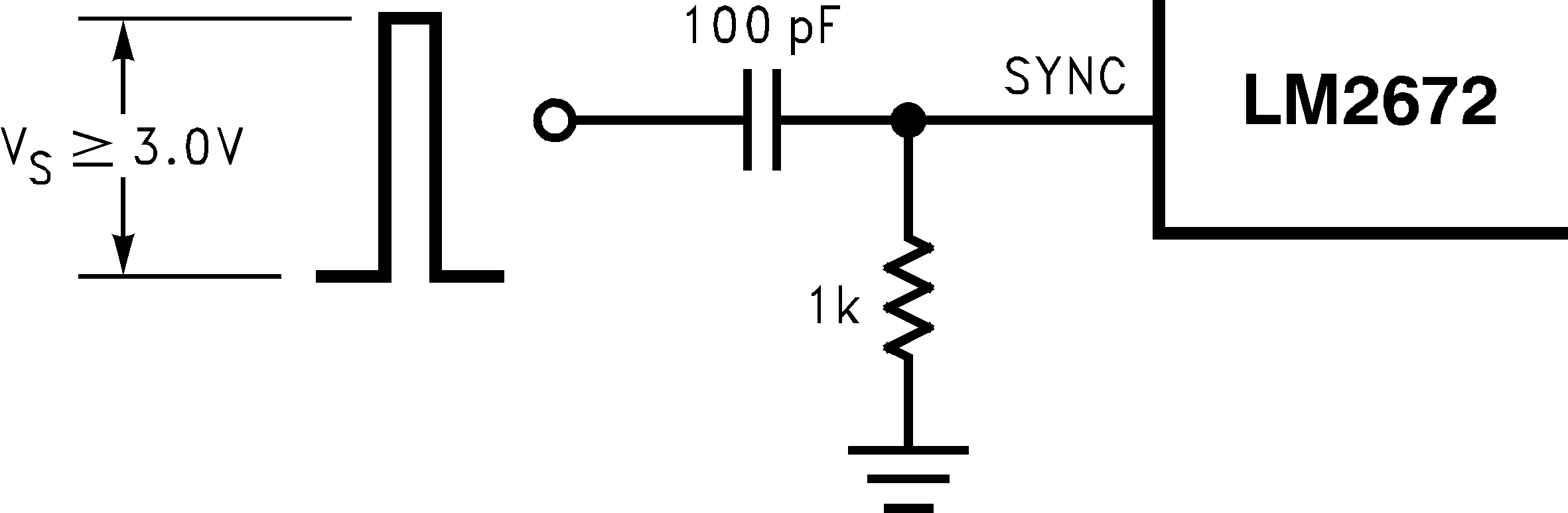

10.2.1.2.7 Frequency Synchronization (Optional)

The LM2672 (oscillator) can be synchronized to run with an external oscillator, using the sync pin (pin 3). By doing so, the LM2672 can be operated at higher frequencies than the standard frequency of 260 kHz. This allows for a reduction in the size of the inductor and output capacitor.

As shown in Figure 22, a signal applied to a RC filter at the sync pin causes the device to synchronize to the frequency of that signal. For a signal with a peak-to-peak amplitude of 3 V or greater, a 1-kΩ resistor and a 100-pF capacitor are suitable values. For all applications, use a 1-kΩ resistor and a 100-pF capacitor for the RC filter.

Figure 22. Synchronization on LM2672

Figure 22. Synchronization on LM2672

10.2.1.3 Application Curves

Figure 23. LM2672, 3.3-V Output

Figure 23. LM2672, 3.3-V Output

Figure 25. LM2672, 12-V Output

Figure 25. LM2672, 12-V Output

Figure 24. LM2672, 5-V Output

Figure 24. LM2672, 5-V Output

10.2.2 Typical Application for Adjustable Output Voltage Versions

COUT = 47-μF, 25-V Tantalum, Sprague 595D Series

D1 = 3.3-A, 50-V Schottky Rectifier, IR 30WQ05F

L1 = 68-μH Sumida #RCR110D-680L

R1 = 1.5-kΩ , 1%

CB = 0.01-μF, 50-V Ceramic

10.2.2.1 Design Requirements

Table 6 lists the design requirements for the adjustable output voltage application.

Table 6. Adjustable Output Voltage Application Parameters

| PARAMETERS | VALUE |

|---|---|

| Regulated output voltage, VOUT | 20 V |

| Maximum input voltage, VIN(max) | 28 V |

| Maximum load current, ILOAD(max) | 1 A |

| Switching frequency, F | Fixed at a nominal 260 kHz |

10.2.2.2 Detailed Design Procedure

10.2.2.2.1 Programming Output Voltage

For this application, TI recommends selecting R1 and R2, as shown in Parameter Measurement Information.

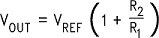

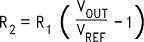

Use Equation 3 to select the appropriate resistor values.

where

- VREF = 1.21 V

Select a value for R1 between 240 Ω and 1.5 kΩ. The lower resistor values minimize noise pickup in the sensitive feedback pin. For the lowest temperature coefficient and the best stability with time, use 1% metal film resistors as in Equation 4.

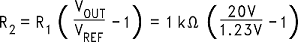

For this application example, select R1 to be 1 kΩ, 1%. Solve for R2 with Equation 5.

R2 = 1 kΩ (16.53 − 1) = 15.53 kΩ, closest 1% value is 15.4 kΩ.

R2 = 15.4 kΩ.

10.2.2.2.2 Inductor Selection (L1)

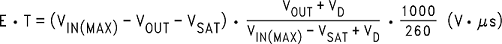

Calculate the inductor Volt × microsecond constant E × T (V × μs) with Equation 6.

where

- VSAT = internal switch saturation voltage = 0.25 V

- VD = diode forward voltage drop = 0.5 V

For this application example, calculate the inductor Volt × microsecond constant (E × T) with Equation 7.

Use the E × T value from the previous formula and match it with the E × T number on the vertical axis of the inductor value selection guide in Figure 27. E × T = 21.6 (V × μs).

On the horizontal axis, select the maximum load current (ILOAD(max) = 1 A).

Identify the inductance region intersected by the E × T value and the maximum load current value. Each region is identified by an inductance value and an inductor code (LXX). From the inductor value selection guide shown in Figure 27, the inductance region intersected by the 21.6 (V × μs) horizontal line and the 1-A vertical line is 68 μH, and the inductor code is L30.

Select an appropriate inductor from the four manufacturer's part numbers listed in Table 2. For information on the different types of inductors, see the inductor selection in the fixed output voltage design procedure. From the table in Table 2, locate line L30, and select an inductor part number from the list of manufacturers' part numbers.

10.2.2.2.3 Output Capacitor SeIection (COUT)

Select an output capacitor from the capacitor code selection guide in Table 7. Using the inductance value found in the inductor selection guide, step 1, locate the appropriate capacitor code corresponding to the desired output voltage. Use the appropriate row of the capacitor code selection guide, in Table 7. For this example, use the 15 to 20 V row. The capacitor code corresponding to an inductance of 68 μH is C20.

Table 7. Capacitor Code Selection Guide

| CASE STYLE(1) | OUTPUT VOLTAGE (V) | INDUCTANCE (μH) | ||||||

|---|---|---|---|---|---|---|---|---|

| 22 | 33 | 47 | 68 | 100 | 150 | 220 | ||

| SM and TH | 1.21 to 2.5 | — | — | — | — | C1 | C2 | C3 |

| SM and TH | 2.5 to 3.75 | — | — | — | C1 | C2 | C3 | C3 |

| SM and TH | 3.75 to 5 | — | — | C4 | C5 | C6 | C6 | C6 |

| SM and TH | 5 to 6.25 | — | C4 | C7 | C6 | C6 | C6 | C6 |

| SM and TH | 6.25 to 7.5 | C8 | C4 | C7 | C6 | C6 | C6 | C6 |

| SM and TH | 7.5 to 10 | C9 | C10 | C11 | C12 | C13 | C13 | C13 |

| SM and TH | 10 to 12.5 | C14 | C11 | C12 | C12 | C13 | C13 | C13 |

| SM and TH | 12.5 to 15 | C15 | C16 | C17 | C17 | C17 | C17 | C17 |

| SM and TH | 15 to 20 | C18 | C19 | C20 | C20 | C20 | C20 | C20 |

| SM and TH | 20 to 30 | C21 | C22 | C22 | C22 | C22 | C22 | C22 |

| TH | 30 to 37 | C23 | C24 | C24 | C25 | C25 | C25 | C25 |

Select an appropriate capacitor value and voltage rating, using the capacitor code, from the output capacitor selection table in Table 8. There are two solid tantalum (surface mount) capacitor manufacturers and four electrolytic (through hole) capacitor manufacturers to choose from. TI recommends that both the manufacturers and the manufacturer's series that are listed in the table be used. From the output capacitor selection table in Table 8, choose a capacitor value (and voltage rating) that intersects the capacitor code(s) selected in section A, C20 (Table 8).

The capacitance and voltage rating values corresponding to the capacitor code C20 are surface mount and through hole.

Surface mount:

- 33-μF, 25-V Sprague 594d series

- 33-μF, 25-V AVX TPS series

Through hole:

- 33-μF, 25-V Sanyo OS-CON SC series

- 120-μF, 35-V Sanyo MV-GX series

- 120-μF, 35-V Nichicon PL series

- 120-μF, 35-V Panasonic HFQ series

Other manufacturers or other types of capacitors may also be used, provided the capacitor specifications (especially the 100 kHz ESR) closely match the characteristics of the capacitors listed in the output capacitor table. Refer to the capacitor manufacturers' data sheet for this information.

Table 8. Output Capacitor Selection Table

| OUTPUT CAPACITOR | ||||||

|---|---|---|---|---|---|---|

| CAP. REF. DESG. # |

SURFACE MOUNT | THROUGH HOLE | ||||

| SPRAGUE 594D SERIES (μF/V) |

AVX TPS SERIES (μF/V) |

SANYO OS-CON SA SERIES (μF/V) |

SANYO MV-GX SERIES (μF/V) |

NICHICON PL SERIES (μF/V) |

PANASONIC HFQ SERIES (μF/V) |

|

| C1 | 120/6.3 | 100/10 | 100/10 | 220/35 | 220/35 | 220/35 |

| C2 | 120/6.3 | 100/10 | 100/10 | 150/35 | 150/35 | 150/35 |

| C3 | 120/6.3 | 100/10 | 100/35 | 120/35 | 120/35 | 120/35 |

| C4 | 68/10 | 100/10 | 68/10 | 220/35 | 220/35 | 220/35 |

| C5 | 100/16 | 100/10 | 100/10 | 150/35 | 150/35 | 150/35 |

| C6 | 100/16 | 100/10 | 100/10 | 120/35 | 120/35 | 120/35 |

| C7 | 68/10 | 100/10 | 68/10 | 150/35 | 150/35 | 150/35 |

| C8 | 100/16 | 100/10 | 100/10 | 330/35 | 330/35 | 330/35 |

| C9 | 100/16 | 100/16 | 100/16 | 330/35 | 330/35 | 330/35 |

| C10 | 100/16 | 100/16 | 68/16 | 220/35 | 220/35 | 220/35 |

| C11 | 100/16 | 100/16 | 68/16 | 150/35 | 150/35 | 150/35 |

| C12 | 100/16 | 100/16 | 68/16 | 120/35 | 120/35 | 120/35 |

| C13 | 100/16 | 100/16 | 100/16 | 120/35 | 120/35 | 120/35 |

| C14 | 100/16 | 100/16 | 100/16 | 220/35 | 220/35 | 220/35 |

| C15 | 47/20 | 68/20 | 47/20 | 220/35 | 220/35 | 220/35 |

| C16 | 47/20 | 68/20 | 47/20 | 150/35 | 150/35 | 150/35 |

| C17 | 47/20 | 68/20 | 47/20 | 120/35 | 120/35 | 120/35 |

| C18 | 68/25 | (2×) 33/25 | 47/25(1) | 220/35 | 220/35 | 220/35 |

| C19 | 33/25 | 33/25 | 33/25(1) | 150/35 | 150/35 | 150/35 |

| C20 | 33/25 | 33/25 | 33/25(1) | 120/35 | 120/35 | 120/35 |

| C21 | 33/35 | (2×) 22/25 | See(2) | 150/35 | 150/35 | 150/35 |

| C22 | 33/35 | 22/35 | See(2) | 120/35 | 120/35 | 120/35 |

| C23 | See(2) | See(2) | See(2) | 220/50 | 100/50 | 120/50 |

| C24 | See(2) | See(2) | See(2) | 150/50 | 100/50 | 120/50 |

| C25 | See(2) | See(2) | See(2) | 150/50 | 82/50 | 82/50 |

10.2.2.2.4 Catch Diode Selection (D1)

In normal operation, the average current of the catch diode is the load current times the catch diode duty cycle, 1-D (D is the switch duty cycle, which is approximately VOUT / VIN). The largest value of the catch diode average current occurs at the maximum input voltage (minimum D). For normal operation, the catch diode current rating must be at least 1.3 times greater than its maximum average current. However, if the power supply design must withstand a continuous output short, the diode must have a current rating greater than the maximum current limit of the LM2672. The most stressful condition for this diode is a shorted output condition. Refer to the table shown in Table 4. Schottky diodes provide the best performance, and in this example a 1-A, 40-V Schottky diode would be a good choice. If the circuit must withstand a continuous shorted output, a higher current (at least 2.2-A) Schottky diode is recommended.

The reverse voltage rating of the diode must be at least 1.25 times the maximum input voltage. Because of their fast switching speed and low forward voltage drop, Schottky diodes provide the best performance and efficiency. The Schottky diode must be placed close to the LM2672 using short leads and short printed circuit traces.

10.2.2.2.5 Input Capacitor (CIN)

A low ESR aluminum or tantalum bypass capacitor is required between the input pin and ground to prevent large voltage transients from appearing at the input. This capacitor must be placed close to the IC using short leads. In addition, the RMS current rating of the input capacitor must be selected to be at least ½ the DC load current. The capacitor manufacturer data sheet must be checked to assure that this current rating is not exceeded. Figure 21 shows typical RMS current ratings for several different aluminum electrolytic capacitor values. A parallel connection of two or more capacitors may be required to increase the total minimum RMS current rating to suit the application requirements.

For an aluminum electrolytic capacitor, the voltage rating must be at least 1.25 times the maximum input voltage. Caution must be exercised if solid tantalum capacitors are used. The tantalum capacitor voltage rating must be twice the maximum input voltage. The tables in Table 5 show the recommended application voltage for AVX TPS and Sprague 594D tantalum capacitors. It is also recommended that they be surge current tested by the manufacturer. The TPS series available from AVX, and the 593D and 594D series from Sprague are all surge current tested. Another approach to minimize the surge current stresses on the input capacitor is to add a small inductor in series with the input supply line.

Use caution when using ceramic capacitors for input bypassing, because it may cause severe ringing at the VIN pin.

The important parameters for the input capacitor are the input voltage rating and the RMS current rating. With a maximum input voltage of 28 V, an aluminum electrolytic capacitor with a voltage rating of at least 35 V (1.25 × VIN) is required.

The RMS current rating requirement for the input capacitor in a buck regulator is approximately ½ the DC load current. In this example, with a 1-A load, a capacitor with a RMS current rating of at least 500 mA is required. The curves shown in Figure 21 can be used to select an appropriate input capacitor. From the curves, locate the 35-V line and note which capacitor values have RMS current ratings greater than 500 mA.

For a through hole design, a 330-μF, 35-V electrolytic capacitor (Panasonic HFQ series, Nichicon PL, Sanyo MV-GX series or equivalent) would be adequate. Other types or other manufacturers' capacitors can be used provided the RMS ripple current ratings are adequate. Additionally, for a complete surface mount design, electrolytic capacitors such as the Sanyo CV-C or CV-BS and the Nichicon WF or UR and the NIC Components NACZ series could be considered.

For surface mount designs, solid tantalum capacitors can be used, but caution must be exercised with regard to the capacitor surge current rating and voltage rating. In this example, checking Table 5, and the Sprague 594D series datasheet, a Sprague 594D 15-μF, 50-V capacitor is adequate.

10.2.2.2.6 Boost Capacitor (CB)

This capacitor develops the necessary voltage to turn the switch gate on fully. All applications must use a

0.01-μF, 50-V ceramic capacitor. If the soft-start and frequency synchronization features are desired, see steps 6 and 7 in the fixed output design procedure.

10.2.2.3 Application Curve

Figure 27. LM2672, Adjustable Output

Figure 27. LM2672, Adjustable Output