SNOSB38C January 2009 – November 2017 LM3241

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- YZR|6

Thermal pad, mechanical data (Package|Pins)

Orderable Information

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM3241 is a synchronous step-down converter in which output voltage is adjusted by a controlled voltage. The following section discusses the design of the external components to complete the power supply design for several input and output voltage options by using typical applications as a reference.

8.2 Typical Application

Figure 29. LM3241 Typical Application Schematic

Figure 29. LM3241 Typical Application Schematic

8.2.1 Design Requirements

For this design example, use the parameters listed in Table 1.

Table 1. Design Parameters

| DESIGN PARAMETER | EXAMPLE VALUE |

|---|---|

| Input voltage | 2.7 V to 5.5 V |

| Output voltage | 0.8 V |

| Maximum current | 750 mA |

8.2.2 Detailed Design Procedure

Table 2 lists the component descriptions for Figure 29.

Table 2. List of Components

| REFERENCE | DESCRIPTION | MANUFACTURER |

|---|---|---|

| C1 | 10 μF, Ceramic capacitor, 6.3 V, X5R, size 0603, GRM188R60J106ME47D | Murata |

| C2 | 4.7 μF, Ceramic capacitor, 6.3 V, X5R, size 0603, GRM188R71H472KA01D | Murata |

| L1 | 0.47 μH, Fixed Inductor, 1.6 A, size 0806, LQM2MPNR47NG0L | Murata |

8.2.2.1 Setting the Output Voltage

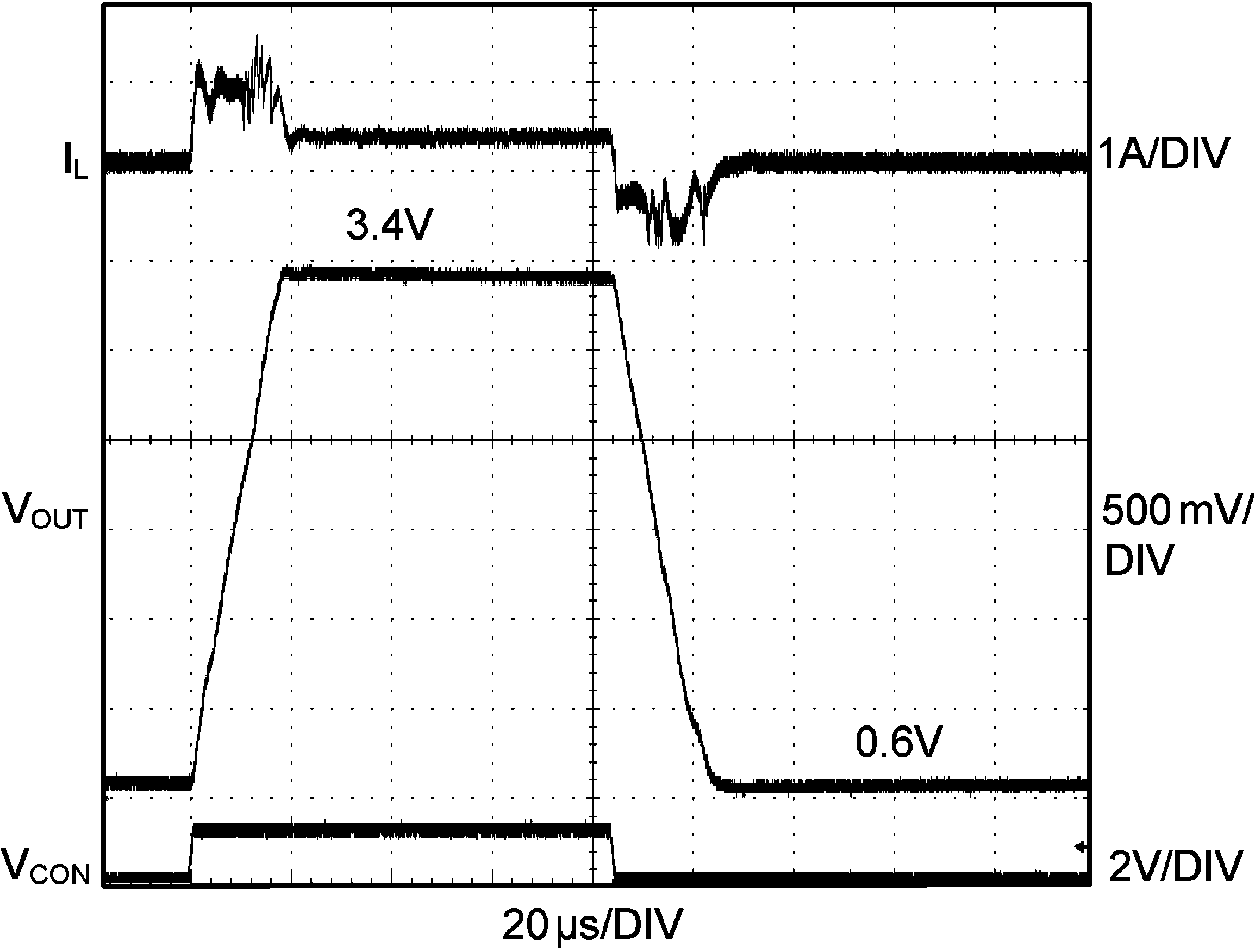

The LM3241 features a pin-controlled adjustable output voltage to eliminate the need for external feedback resistors. The output voltage can be programmed for an output voltage from 0.6 V to 3.4 V by setting the voltage on the VCON pin, as shown in Equation 1.

When the VCON voltage is between 0.24 V and 1.36 V, the output voltage follows proportionally by 2.5 times of VCON.

If the VCON voltage is less than 0.24 V (VOUT = 0.6 V), the output voltage may be regulated (for details see Figure 17). Figure 17 exhibits the characteristics of a typical part, and the performance cannot be ensured as a part-to-part variation could occur for output voltages less than 0.6 V. For VOUT lower than 0.6 V, the converter could suffer from larger output ripple voltage and higher current limit operation.

8.2.2.2 Inductor Selection

Two main considerations must be considered when choosing an inductor: the inductor should not saturate, and the inductor current ripple should be small enough to achieve the desired output voltage ripple. Different manufacturers follow different saturation current rating specifications, so attention must be given to details. Saturation current ratings are typically specified at 25°C so ratings over the ambient temperature of application should be requested from manufacturer.

The minimum value of inductance to ensure good performance is 0.3 µH at bias current (ILIM, typical) over the ambient temperature range. Shielded inductors radiate less noise and should be preferred. Two methods are avaialble to choose the inductor saturation current rating.

8.2.2.2.1 Method 1

The saturation current should be greater than the sum of the maximum load current and the worst case average to peak inductor current. Use Equation 2 to find the saturation current (ISAT).

where

- IOUT_MAX is the maximum load current (750 mA).

- IRIPPLE is the average-to-peak inductor current. Use Equation 3 to calculate the IRIPPLE value.

where

- VIN is the maximum input voltage in application.

- VOUT is the output voltage

- L is the minimum inductor value including worst-case tolerances (30% drop can be considered for Method 1)

- f is the minimum switching frequency (5.7 MHz)

8.2.2.2.2 Method 2

A more conservative and recommended approach is to choose an inductor that can support the maximum current limit of 1600 mA.

The resistance of the inductor should be less than approximately 0.1 Ω for good efficiency. Table 3 lists recommended inductors and suppliers.

Table 3. Recommended Inductors

| Model | Size (W x L x H) (mm) | Vendor |

|---|---|---|

| MIPSZ2012D0R5 | 2.0 x 1.2 x 1.0 | FDK |

| LQM21PNR54MG0 | 2.0 x 1.25 x 0.9 | Murata |

| LQM2MPNR47NG0 | 2.0 x 1.6 x 0.9 | Murata |

8.2.2.3 Capacitor Selection

The LM3241 is designed for use with ceramic capacitors for its input and output filters. Use a 10-µF ceramic capacitor for the input and a 4.7-µF ceramic capacitor for the output. The capacitors should maintain at least 50% capacitance at DC bias and temperature conditions. Ceramic capacitors type such as X5R, X7R, and B are recommended for both filters. These types provide an optimal balance between small size, cost, reliability, and performance for cell phones and similar applications. Table 4 lists some recommended part numbers and suppliers. DC bias characteristics of the capacitors must be considered when selecting the voltage rating and case size of the capacitor. For CIN, use of an 0805 (2012) size may also be considered if room is available on the system board.

Table 4. Recommended Capacitors

| Capacitance, Voltage Rating, Case Size | Model | Vendor |

|---|---|---|

| 4.7 µF, 6.3 V, 0603 | C1608X5R0J475M | TDK |

| 4.7 µF, 6.3 V, 0402 | C1005X5R0J475M | TDK |

| 4.7 µF, 6.3 V, 0402 | CL05A475MQ5NRNC | Samsung |

| 10 µF, 6.3 V, 0603 | C1608X5R0J106M | TDK |

| 10 µF, 6.3 V, 0402 | CL05A106MQ5NUNC | Samsung |

The input filter capacitor supplies AC current drawn by the PFET switch of the LM3241 in the first part of each cycle and reduces the voltage ripple imposed on the input power source. The output filter capacitor absorbs the AC inductor current, helps maintain a steady output voltage during transient load changes, and reduces output voltage ripple. These capacitors must be selected with sufficient capacitance and sufficiently low equivalent series resistance (ESR) to perform these functions. The ESR of the filter capacitors is generally a major factor in voltage ripple.

8.2.3 Application Curves

| VOUT = 0.8 V |

| VOUT = 0.6 V/3.4 V | RLOAD = 10 Ω |