SNVSAX8 April 2018 LM3478Q-Q1

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Applications

- 8.2.1

Typical High Efficiency Step-Up (Boost) Converter

- 8.2.1.1 Design Requirements

- 8.2.1.2

Detailed Design Procedure

- 8.2.1.2.1 Custom Design with WEBENCH Tools

- 8.2.1.2.2 Power Inductor Selection

- 8.2.1.2.3 Programming the Output Voltage

- 8.2.1.2.4 Setting the Current Limit

- 8.2.1.2.5 Current Limit with External Slope Compensation

- 8.2.1.2.6 Power Diode Selection

- 8.2.1.2.7 Power MOSFET Selection

- 8.2.1.2.8 Input Capacitor Selection

- 8.2.1.2.9 Output Capacitor Selection

- 8.2.1.2.10 Compensation

- 8.2.1.3 Application Curves

- 8.2.2 Typical SEPIC Converter

- 8.2.1

Typical High Efficiency Step-Up (Boost) Converter

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DGK|8

Thermal pad, mechanical data (Package|Pins)

- DGK|8

Orderable Information

8.2.1.2.8 Input Capacitor Selection

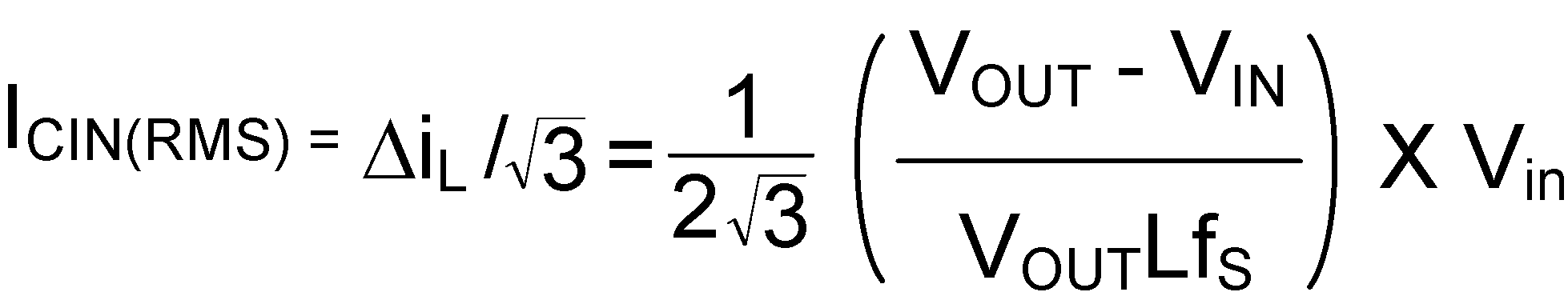

Due to the presence of an inductor at the input of a boost converter, the input current waveform is continuous and triangular as shown in Figure 29. The inductor ensures that the input capacitor sees fairly low ripple currents. However, as the input capacitor gets smaller, the input ripple goes up. The RMS current in the input capacitor is given using Equation 31.

The input capacitor should be capable of handling the RMS current. Although the input capacitor is not as critical in a boost application, low values can cause impedance interactions. Therefore a good quality capacitor should be chosen in the range of 10 µF to 20 µF. If a value lower than 10 µF is used, then problems with impedance interactions or switching noise can affect the LM3478Q-Q1. To improve performance, especially with Vin below 8 volts, it is recommended to use a 20 Ohm resistor at the input to provide an RC filter. The resistor is placed in series with the VIN pin with only a bypass capacitor attached to the VIN pin directly (see Figure 31). A 0.1-µF or 1-µF ceramic capacitor is necessary in this configuration. The bulk input capacitor and inductor will connect on the other side of the resistor at the input power supply.

Figure 31. Reducing IC Input Noise

Figure 31. Reducing IC Input Noise