SNOSAR2H September 2008 – April 2016 LMP8601 , LMP8601-Q1 , LMP8602 , LMP8602-Q1 , LMP8603 , LMP8603-Q1

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- D|8

Thermal pad, mechanical data (Package|Pins)

Orderable Information

10 Layout

10.1 Layout Guidelines

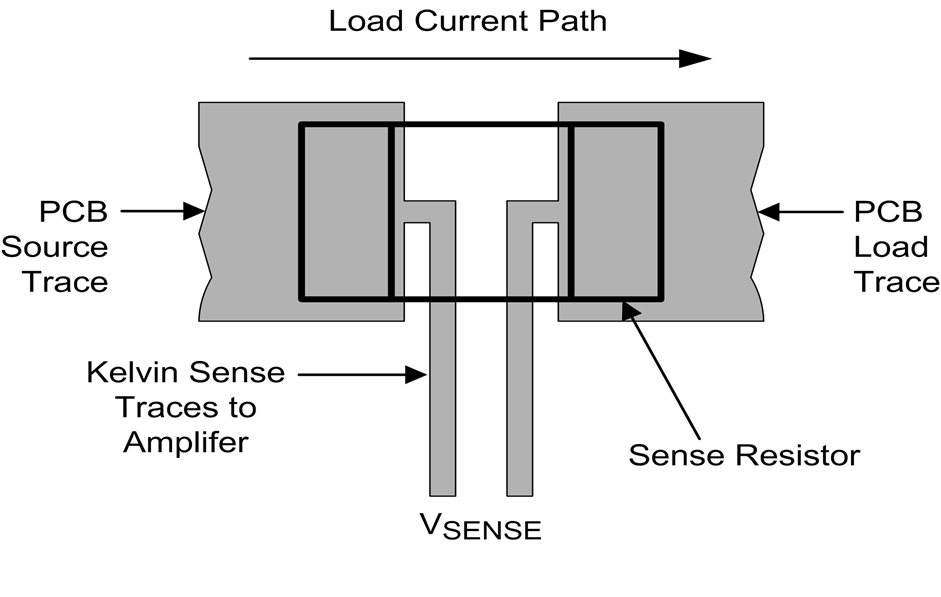

The traces leading to and from the sense resistor can be significant error sources. With small value sense resistors (< 100 mΩ), any trace resistance shared with the load current can cause significant errors.

The amplifier inputs should be directly connected to the sense resistor pads using Kelvin or 4-wire connection techniques. The traces should be one continuous piece of copper from the sense resistor pad to the amplifier input pin pad, and ideally on the same copper layer with minimal vias or connectors. This can be important around the sense resistor if it is generating any significant heat gradients.

To minimize noise pickup and thermal errors, the input traces should be treated as a differential signal pair and routed tightly together with a direct path to the input pins. The input traces should be run away from noise sources, such as digital lines, switching supplies or motor drive lines. Remember that these traces can contain high voltage, and should have the appropriate trace routing clearances.

Since the sense traces only carry the amplifier bias current, the connecting input traces can be thinner, signal level traces. Excessive Resistance in the trace should also be avoided.

The paths of the traces should be identical, including connectors and vias, so that any errors will be equal and cancel.

The sense resistor will heat up as the load increases. As the resistor heats up, the resistance generally goes up, which will cause a change in the readings. The sense resistor should have as much heatsinking as possible to remove this heat through the use of heatsinks or large copper areas coupled to the resistor pads. A reading drifting over time after turnon can usually be traced back to sense resistor heating.

10.2 Layout Example

Figure 66. Kelvin or 4–wire Connection to the Sense Resistor

Figure 66. Kelvin or 4–wire Connection to the Sense Resistor