SNVS636O December 2009 – August 2015 LMZ12003

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- NDW|7

Thermal pad, mechanical data (Package|Pins)

Orderable Information

7 Detailed Description

7.1 Overview

The LMZ12003 power module is an easy-to-use step-down DC-DC solution capable of driving up to 3-A load with exceptional power conversion efficiency, line and load regulation, and output accuracy.

7.2 Functional Block Diagram

7.3 Feature Description

7.3.1 COT Control Circuit Overview

Constant ON-Time control is based on a comparator and an ON-time one-shot, with the output voltage feedback compared with an internal 0.8-V reference. If the feedback voltage is below the reference, the main MOSFET is turned on for a fixed ON-time determined by a programming resistor RON. RON is connected to VIN such that ON-time is reduced with increasing input supply voltage. Following this ON-time, the main MOSFET remains off for a minimum of 260 ns. If the voltage on the feedback pin falls below the reference level again the ON-time cycle is repeated. Regulation is achieved in this manner.

7.3.2 Output Overvoltage Comparator

The voltage at FB is compared to a 0.92-V internal reference. If FB rises above 0.92 V the ON-time is immediately terminated. This condition is known as overvoltage protection (OVP). It can occur if the input voltage is increased very suddenly or if the output load is decreased very suddenly. Once OVP is activated, the top MOSFET ON-times will be inhibited until the condition clears. Additionally, the synchronous MOSFET will remain on until inductor current falls to zero.

7.3.3 Current Limit

Current limit detection is carried out during the OFF-time by monitoring the current in the synchronous MOSFET. Referring to the Functional Block Diagram, when the top MOSFET is turned off, the inductor current flows through the load, the PGND pin and the internal synchronous MOSFET. If this current exceeds 4.2 A (typical) the current limit comparator disables the start of the next ON-time period. The next switching cycle will occur only if the FB input is less than 0.8 V and the inductor current has decreased below 4.2 A. Inductor current is monitored during the period of time the synchronous MOSFET is conducting. So long as inductor current exceeds 4.2 A, further ON-time intervals for the top MOSFET will not occur. Switching frequency is lower during current limit due to the longer OFF-time.

NOTE

Current limit is dependent on both duty cycle and temperature as illustrated in the graphs in the Typical Characteristics section.

7.3.4 Thermal Protection

The junction temperature of the LMZ12003 should not be allowed to exceed its maximum ratings. Thermal protection is implemented by an internal Thermal Shutdown circuit which activates at 165°C (typical) causing the device to enter a low power standby state. In this state the main MOSFET remains off causing VO to fall, and additionally the CSS capacitor is discharged to ground. Thermal protection helps prevent catastrophic failures for accidental device overheating. When the junction temperature falls back below 145ºC (typical hysteresis = 20°C) the SS pin is released, VO rises smoothly, and normal operation resumes.

Applications requiring maximum output current especially those at high input voltage may require application derating at elevated temperatures.

7.3.5 Zero Coil Current Detection

The current of the lower (synchronous) MOSFET is monitored by a zero coil current detection circuit which inhibits the synchronous MOSFET when its current reaches zero until the next ON-time. This circuit enables the DCM operating mode, which improves efficiency at light loads.

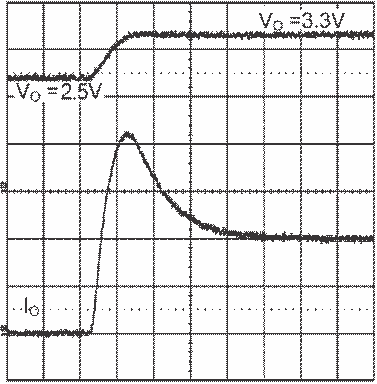

7.3.6 Prebiased Start-Up

The LMZ12003 will properly start up into a prebiased output. This startup situation is common in multiple rail logic applications where current paths may exist between different power rails during the start-up sequence. The following scope capture shows proper behavior during this event.

Figure 15. Prebiased Start-Up

Figure 15. Prebiased Start-Up

7.4 Device Functional Modes

7.4.1 Discontinuous Conduction and Continuous Conduction Modes

At light load the regulator will operate in discontinuous conduction mode (DCM). With load currents above the critical conduction point, it will operate in continuous conduction mode (CCM). When operating in DCM the switching cycle begins at zero amps inductor current; increases up to a peak value, and then recedes back to zero before the end of the OFF-time. Note that during the period of time that inductor current is zero, all load current is supplied by the output capacitor. The next ON-time period starts when the voltage on the at the FB pin falls below the internal reference. The switching frequency is lower in DCM and varies more with load current as compared to CCM. Conversion efficiency in DCM is maintained because conduction and switching losses are reduced with the smaller load and lower switching frequency.