SPNS183C September 2012 – June 2015 RM46L440 , RM46L840

PRODUCTION DATA.

- 1Device Overview

- 2Revision History

- 3Device Comparison

-

4Terminal Configuration and Functions

- 4.1 PGE QFP Package Pinout (144-Pin)

- 4.2 ZWT BGA Package Ball-Map (337 Ball Grid Array)

- 4.3

Terminal Functions

- 4.3.1

PGE Package

- 4.3.1.1 Multibuffered Analog-to-Digital Converters (MibADC)

- 4.3.1.2 Enhanced High-End Timer Modules (N2HET)

- 4.3.1.3 Enhanced Capture Modules (eCAP)

- 4.3.1.4 Enhanced Quadrature Encoder Pulse Modules (eQEP)

- 4.3.1.5 Enhanced Pulse-Width Modulator Modules (ePWM)

- 4.3.1.6 General-Purpose Input / Output (GPIO)

- 4.3.1.7 Controller Area Network Controllers (DCAN)

- 4.3.1.8 Local Interconnect Network Interface Module (LIN)

- 4.3.1.9 Standard Serial Communication Interface (SCI)

- 4.3.1.10 Inter-Integrated Circuit Interface Module (I2C)

- 4.3.1.11 Standard Serial Peripheral Interface (SPI)

- 4.3.1.12 Multibuffered Serial Peripheral Interface Modules (MibSPI)

- 4.3.1.13 Ethernet Controller

- 4.3.1.14 System Module Interface

- 4.3.1.15 Clock Inputs and Outputs

- 4.3.1.16 Test and Debug Modules Interface

- 4.3.1.17 Flash Supply and Test Pads

- 4.3.1.18 Supply for Core Logic: 1.2V nominal

- 4.3.1.19 Supply for I/O Cells: 3.3V nominal

- 4.3.1.20 Ground Reference for All Supplies Except VCCAD

- 4.3.2

ZWT Package

- 4.3.2.1 Multibuffered Analog-to-Digital Converters (MibADC)

- 4.3.2.2 Enhanced High-End Timer Modules (N2HET)

- 4.3.2.3 Enhanced Capture Modules (eCAP)

- 4.3.2.4 Enhanced Quadrature Encoder Pulse Modules (eQEP)

- 4.3.2.5 Enhanced Pulse-Width Modulator Modules (ePWM)

- 4.3.2.6 General-Purpose Input / Output (GPIO)

- 4.3.2.7 Controller Area Network Controllers (DCAN)

- 4.3.2.8 Local Interconnect Network Interface Module (LIN)

- 4.3.2.9 Standard Serial Communication Interface (SCI)

- 4.3.2.10 Inter-Integrated Circuit Interface Module (I2C)

- 4.3.2.11 Standard Serial Peripheral Interface (SPI)

- 4.3.2.12 Multibuffered Serial Peripheral Interface Modules (MibSPI)

- 4.3.2.13 Ethernet Controller

- 4.3.2.14 External Memory Interface (EMIF)

- 4.3.2.15 System Module Interface

- 4.3.2.16 Clock Inputs and Outputs

- 4.3.2.17 Test and Debug Modules Interface

- 4.3.2.18 Flash Supply and Test Pads

- 4.3.2.19 Reserved

- 4.3.2.20 No Connects

- 4.3.2.21 Supply for Core Logic: 1.2V nominal

- 4.3.2.22 Supply for I/O Cells: 3.3V nominal

- 4.3.2.23 Ground Reference for All Supplies Except VCCAD

- 4.3.1

PGE Package

-

5Specifications

- 5.1 Absolute Maximum Ratings Over Operating Free-Air Temperature Range

- 5.2 ESD Ratings

- 5.3 Power-On Hours (POH)

- 5.4 Device Recommended Operating Conditions

- 5.5 Switching Characteristics Over Recommended Operating Conditions for Clock Domains

- 5.6 Wait States Required

- 5.7 Power Consumption Over Recommended Operating Conditions

- 5.8 Input/Output Electrical Characteristics Over Recommended Operating Conditions

- 5.9 Thermal Resistance Characteristics

- 5.10 Output Buffer Drive Strengths

- 5.11 Input Timings

- 5.12 Output Timings

- 5.13 Low-EMI Output Buffers

-

6System Information and Electrical Specifications

- 6.1 Device Power Domains

- 6.2 Voltage Monitor Characteristics

- 6.3 Power Sequencing and Power On Reset

- 6.4 Warm Reset (nRST)

- 6.5 ARM Cortex-R4F CPU Information

- 6.6 Clocks

- 6.7 Clock Monitoring

- 6.8 Glitch Filters

- 6.9 Device Memory Map

- 6.10 Flash Memory

- 6.11 Tightly Coupled RAM Interface Module

- 6.12 Parity Protection for Accesses to Peripheral RAMs

- 6.13 On-Chip SRAM Initialization and Testing

- 6.14 External Memory Interface (EMIF)

- 6.15 Vectored Interrupt Manager

- 6.16 DMA Controller

- 6.17 Real Time Interrupt Module

- 6.18 Error Signaling Module

- 6.19 Reset / Abort / Error Sources

- 6.20 Digital Windowed Watchdog

- 6.21 Debug Subsystem

-

7Peripheral Information and Electrical Specifications

- 7.1

Enhanced Translator PWM Modules (ePWM)

- 7.1.1 ePWM Clocking and Reset

- 7.1.2 Synchronization of ePWMx Time Base Counters

- 7.1.3 Synchronizing all ePWM Modules to the N2HET1 Module Time Base

- 7.1.4 Phase-Locking the Time-Base Clocks of Multiple ePWM Modules

- 7.1.5 ePWM Synchronization with External Devices

- 7.1.6 ePWM Trip Zones

- 7.1.7 Triggering of ADC Start of Conversion Using ePWMx SOCA and SOCB Outputs

- 7.1.8 Enhanced Translator-Pulse Width Modulator (ePWMx) Timings

- 7.2 Enhanced Capture Modules (eCAP)

- 7.3 Enhanced Quadrature Encoder (eQEP)

- 7.4 Multibuffered 12bit Analog-to-Digital Converter

- 7.5 General-Purpose Input/Output

- 7.6 Enhanced High-End Timer (N2HET)

- 7.7 Controller Area Network (DCAN)

- 7.8 Local Interconnect Network Interface (LIN)

- 7.9 Serial Communication Interface (SCI)

- 7.10 Inter-Integrated Circuit (I2C)

- 7.11 Multibuffered / Standard Serial Peripheral Interface

- 7.12 Ethernet Media Access Controller

- 7.1

Enhanced Translator PWM Modules (ePWM)

- 8Device and Documentation Support

- 9Mechanical Packaging and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- ZWT|337

- PGE|144

Thermal pad, mechanical data (Package|Pins)

Orderable Information

8 Device and Documentation Support

8.1 Device and Development-Support Tool Nomenclature

To designate the stages in the product development cycle, TI assigns prefixes to the part numbers of all devices. Each device has one of three prefixes: X, P, or null (no prefix) (for example, xRM46L852). These prefixes represent evolutionary stages of product development from engineering prototypes through fully qualified production devices/tools.

Device development evolutionary flow:

-

x Experimental device that is not necessarily representative of the final device's electrical specifications and may not use production assembly flow.

-

P Prototype device that is not necessarily the final silicon die and may not necessarily meet final electrical specifications.

-

null Fully-qualified production device.

x and P devices are shipped against the following disclaimer:

"Developmental product is intended for internal evaluation purposes."

Production devices have been characterized fully, and the quality and reliability of the device have been demonstrated fully. TI's standard warranty applies.

Predictions show that prototype devices have a greater failure rate than the standard production devices. Texas Instruments recommends that these devices not be used in any production system because their expected end-use failure rate still is undefined. Only qualified production devices are to be used.

Figure 8-1 shows the numbering and symbol nomenclature for the RM46Lx40 devices.

8.2 Documentation Support

8.2.1 Related Documentation from Texas Instruments

The following documents describe the RM46x microcontroller..

-

SPNU514RM46x 16/32-Bit RISC Flash Microcontroller Technical Reference Manual details the integration, the environment, the functional description, and the programming models for each peripheral and subsystem in the device.

-

SPNZ200RM46x Microcontroller, Silicon Revision B, Silicon Errata describes the usage notes and known exceptions to the functional specifications for the device silicon revision B.

-

SPNZ219RM46x Microcontroller, Silicon Revision C, Silicon Errata describes the usage notes and known exceptions to the functional specifications for the device silicon revision C.

8.2.2 Related Links

The table below lists quick access links. Categories include technical documents, support and community resources, tools and software, and quick access to sample or buy.

Table 8-1 Related Links

| PARTS | PRODUCT FOLDER | SAMPLE & BUY | TECHNICAL DOCUMENTS | TOOLS & SOFTWARE | SUPPORT & COMMUNITY |

|---|---|---|---|---|---|

| RM46L440 | Click here | Click here | Click here | Click here | Click here |

| RM46L840 | Click here | Click here | Click here | Click here | Click here |

8.2.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of Use.

-

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help solve problems with fellow engineers.

-

TI Embedded Processors Wiki Texas Instruments Embedded Processors Wiki. Established to help developers get started with Embedded Processors from Texas Instruments and to foster innovation and growth of general knowledge about the hardware and software surrounding these devices.

8.3 Trademarks

E2E is a trademark of Texas Instruments.

ARM, Cortex are registered trademarks of ARM Limited (or its subsidiaries) in the EU and.

CoreSight is a trademark of ARM Limited.

All other trademarks are the property of their respective owners.

8.4 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

8.5 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

8.6 Device Identification

8.6.1 Device Identification Code Register

The device identification code register identifies several aspects of the device including the silicon version. The details of the device identification code register are shown in Table 8-2. The device identification code register value for this device is:

| 31 | 30 | 29 | 28 | 27 | 26 | 25 | 24 | 23 | 22 | 21 | 20 | 19 | 18 | 17 | 16 |

| CP-15 | UNIQUE ID | TECH | |||||||||||||

| R-1 | R-00000000100011 | R-0 | |||||||||||||

| 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| TECH | I/O VOLTAGE | PERIPH PARITY | FLASH ECC | RAM ECC | VERSION | 1 | 0 | 1 | |||||||

| R-101 | R-0 | R-1 | R-10 | R-1 | R-00011 | R-1 | R-0 | R-1 | |||||||

| LEGEND: R/W = Read/Write; R = Read only; -n = value after reset |

Table 8-2 Device ID Bit Allocation Register Field Descriptions

| Bit | Field | Value | Description |

|---|---|---|---|

| 31 | CP15 | Indicates the presence of coprocessor 15 | |

| 1 | CP15 present | ||

| 30-17 | UNIQUE ID | 100011 | Unique device identification number This bitfield holds a unique number for a dedicated device configuration (die). |

| 16-13 | TECH | Process technology on which the device is manufactured. | |

| 0101 | F021 | ||

| 12 | I/O VOLTAGE | I/O voltage of the device. | |

| 0 | I/O are 3.3v | ||

| 11 | PERIPHERAL PARITY | 1 | Peripheral Parity Parity on peripheral memories |

| 10-9 | FLASH ECC | Flash ECC | |

| 10 | Program memory with ECC | ||

| 8 | RAM ECC | Indicates if RAM memory ECC is present. | |

| 1 | ECC implemented | ||

| 7-3 | REVISION | Revision of the Device. | |

| 2-0 | 101 | The platform family ID is always 0b101 |

8.6.2 Die Identification Registers

The two die ID registers at addresses 0xFFFFFF7C and 0xFFFFFF80 form a 64-bit dieid with the information as shown in Table 8-3.

Table 8-3 Die-ID Registers

| Item | # of Bits | Bit Location |

|---|---|---|

| X Coordinate on Wafer | 12 | 0xFFFFFF7C[11:0] |

| Y Coordinate on Wafer | 12 | 0xFFFFFF7C[23:12] |

| Wafer # | 8 | 0xFFFFFF7C[31:24] |

| Lot # | 24 | 0xFFFFFF80[23:0] |

| Reserved | 8 | 0xFFFFFF80[31:24] |

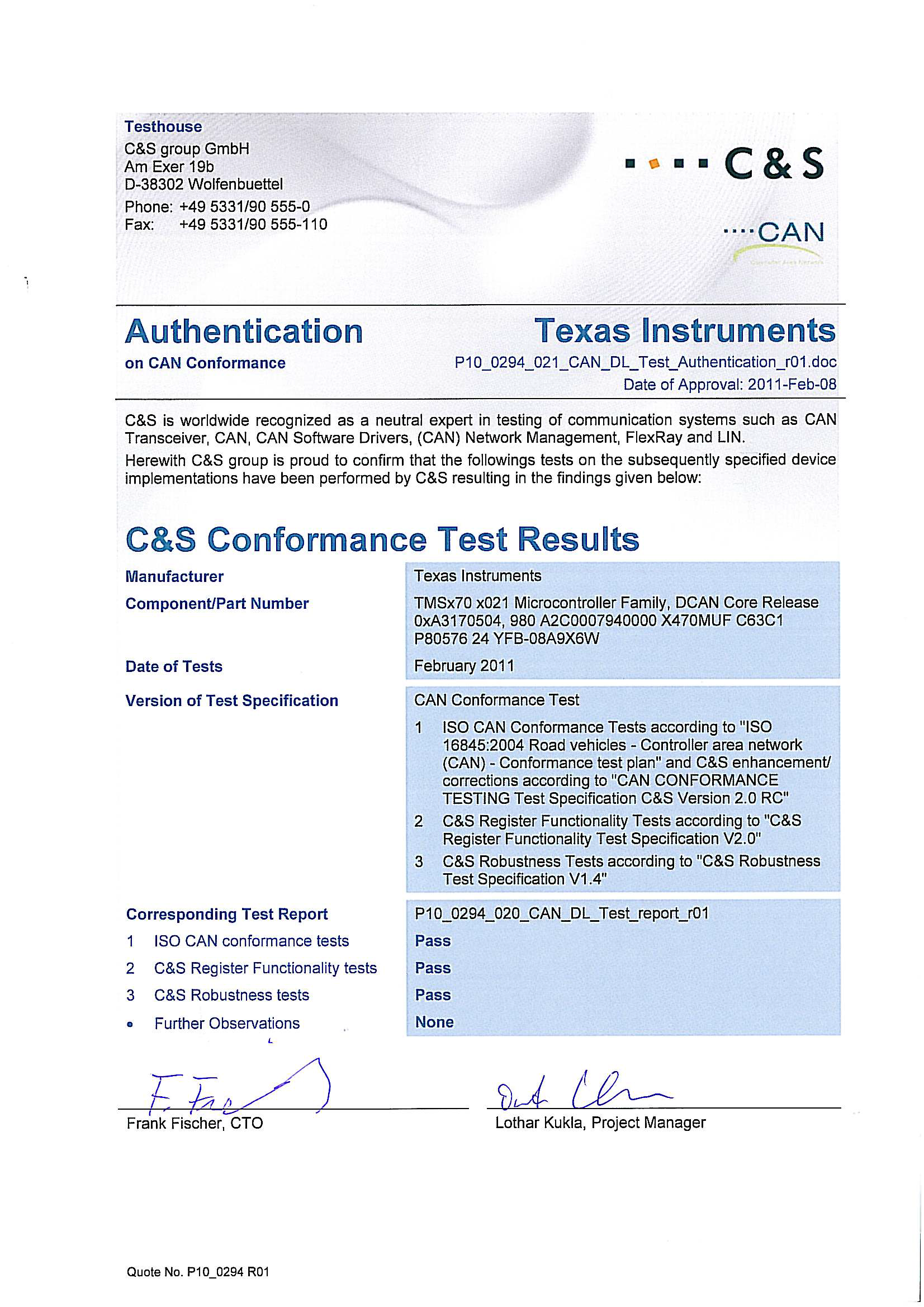

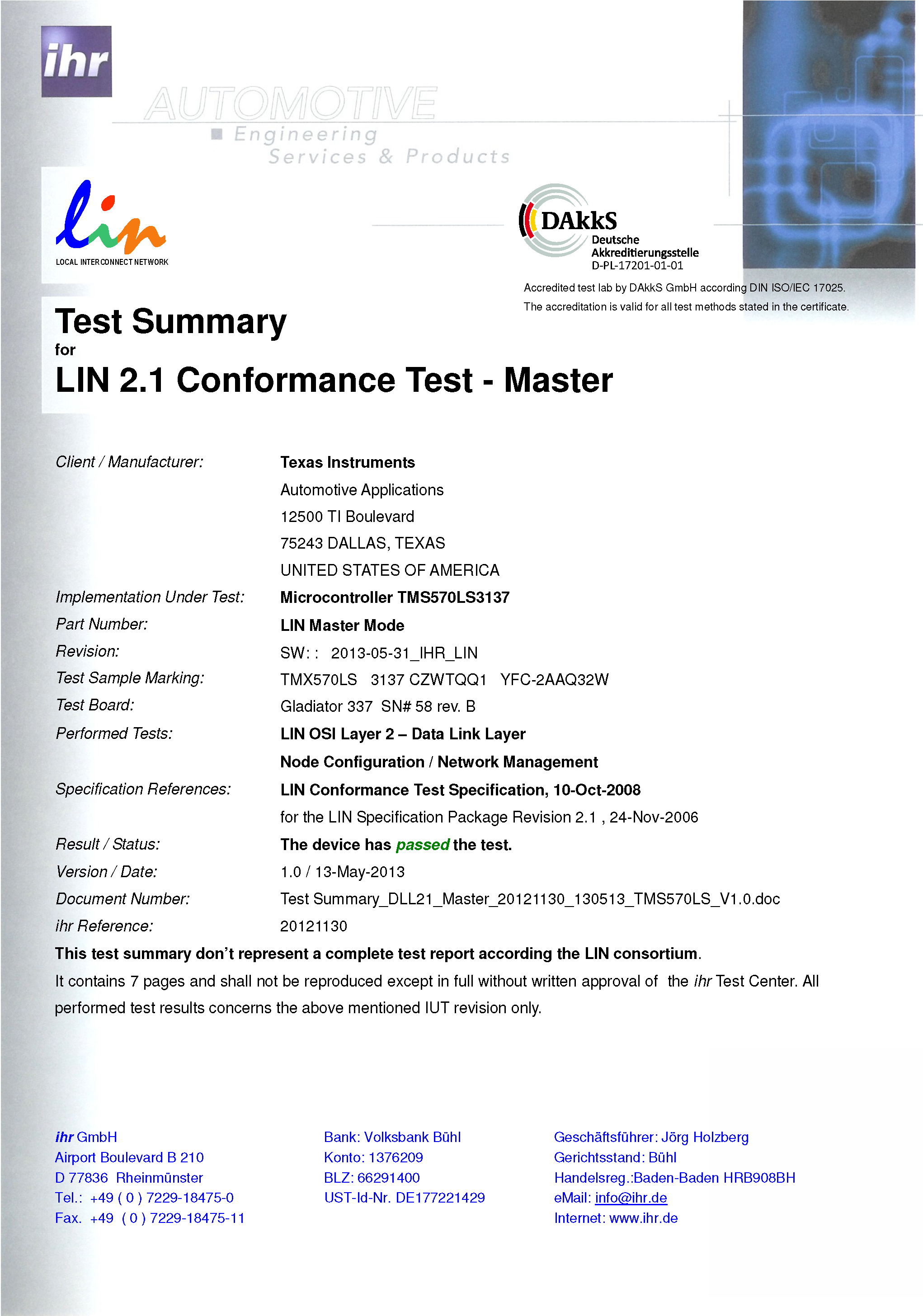

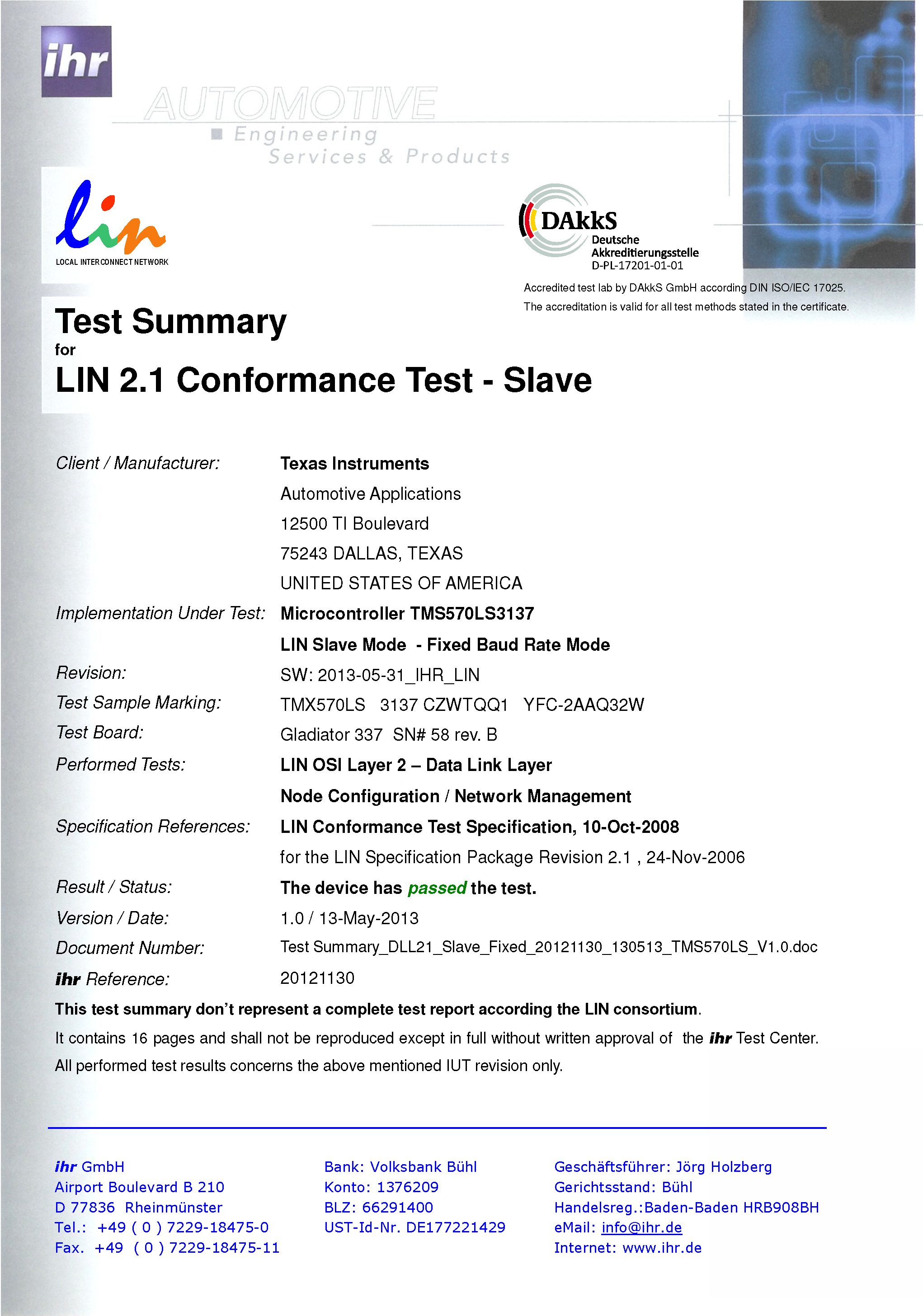

8.7 Module Certifications

The following communications modules have received certification of adherence to a standard.

8.7.1 DCAN Certification

DCAN Certification

DCAN Certification

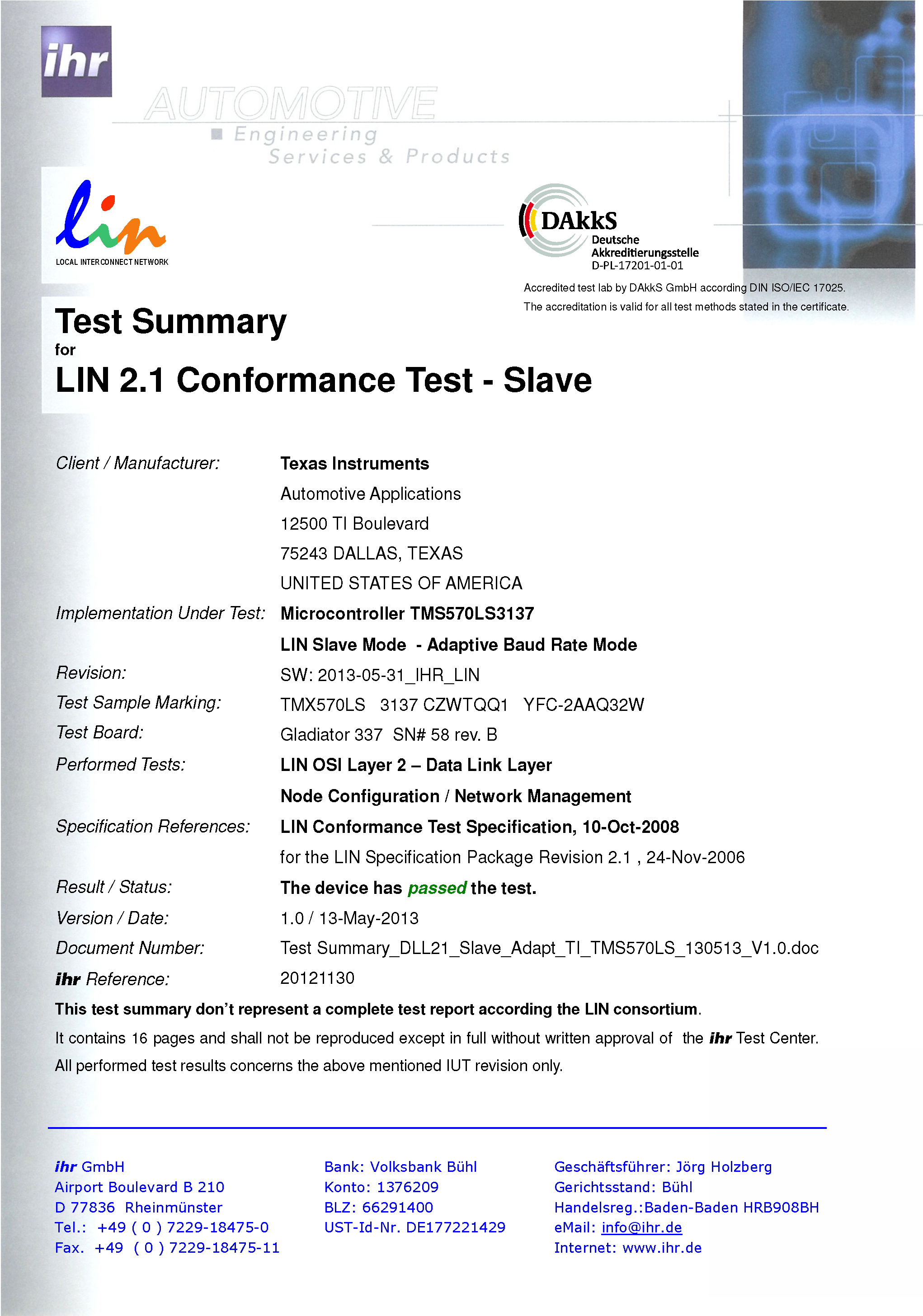

8.7.2 LIN Certification

8.7.2.1 LIN Master Mode

LIN Certification - Master Mode

LIN Certification - Master Mode

8.7.2.2 LIN Slave Mode - Fixed Baud Rate

LIN Certification - Slave Mode - Fixed Baud Rate

LIN Certification - Slave Mode - Fixed Baud Rate

8.7.2.3 LIN Slave Mode - Adaptive Baud Rate

LIN Certification - Slave Mode - Adaptive Baud Rate

LIN Certification - Slave Mode - Adaptive Baud Rate