SLLSEN8C September 2015 – June 2017 TL16C752D

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Description (continued)

- 6 Pin Configurations and Function

- 7 Specifications

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagrams

- 8.3

Feature Description

- 8.3.1

Functional Description

- 8.3.1.1 Trigger Levels

- 8.3.1.2 Hardware Flow Control

- 8.3.1.3 Auto-RTS

- 8.3.1.4 Auto-CTS

- 8.3.1.5 Software Flow Control

- 8.3.1.6 Software Flow Control Example

- 8.3.1.7 Reset

- 8.3.1.8 Interrupts

- 8.3.1.9 Interrupt Mode Operation

- 8.3.1.10 Polled Mode Operation

- 8.3.1.11 Break and Timeout Conditions

- 8.3.1.12 Programmable Baud Rate Generator

- 8.3.1

Functional Description

- 8.4 Device Functional Modes

- 8.5

Register Maps

- 8.5.1 Principals of Operation

- 8.5.2 Receiver Holding Register (RHR)

- 8.5.3 Transmit Holding Register (THR)

- 8.5.4 FIFO Control Register (FCR)

- 8.5.5 Line Control Register (LCR)

- 8.5.6 Line Status Register (LSR)

- 8.5.7 Modem Control Register (MCR)

- 8.5.8 Modem Status Register (MSR)

- 8.5.9 Interrupt Enable Register (IER)

- 8.5.10 Interrupt Identification Register (IIR)

- 8.5.11 Enhanced Feature Register (EFR)

- 8.5.12 Divisor Latches (DLL, DLH)

- 8.5.13 Transmission Control Register (TCR)

- 8.5.14 Trigger Level Register (TLR)

- 8.5.15 FIFO Ready Register

- 8.5.16 Alternate Function Register (AFR)

- 8.5.17 RS-485 Mode

- 8.5.18 IrDA Overview

- 8.5.19 IrDA Encoder Function

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

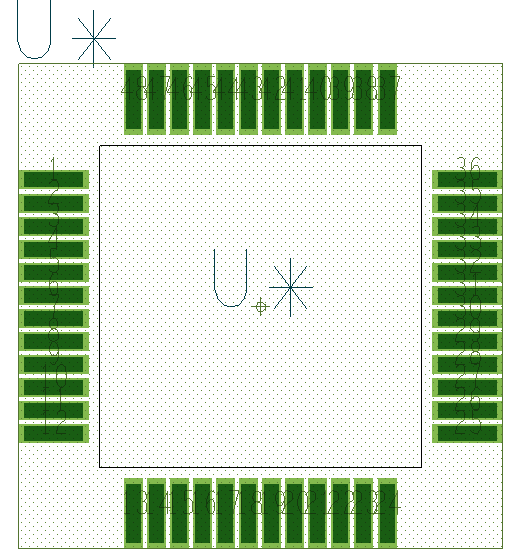

Package Options

Mechanical Data (Package|Pins)

- PFB|48

Thermal pad, mechanical data (Package|Pins)

Orderable Information

11 Layout

11.1 Layout Guidelines

Traces, Vias, and Other PCB Components: A right angle in a trace can cause more radiation. The capacitance increases in the region of the corner, and the characteristic impedance changes. This impedance change causes reflections.

- Avoid right-angle bends in a trace and try to route them at least with two 45° corners. To minimize any impedance change, the best routing would be a round bend (see Figure 24).

- Separate high-speed signals (for example, clock signals) from low-speed signals and digital from analog signals; again, placement is important.

- To minimize crosstalk not only between two signals on one layer but also between adjacent layers, route them with 90° to each other

Figure 44. Layout Do's and Don'ts

11.2 Layout Examples

Figure 45. RS232 Channel Layout Example

Figure 45. RS232 Channel Layout Example

Figure 46. Footprint Example

Figure 46. Footprint Example