SLYS029B July 2021 – June 2022 TMAG5110-Q1 , TMAG5111-Q1

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Detailed Description

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DBV|5

Thermal pad, mechanical data (Package|Pins)

Orderable Information

8.3.2.2 Device Placed on the Side Edge of the Magnet

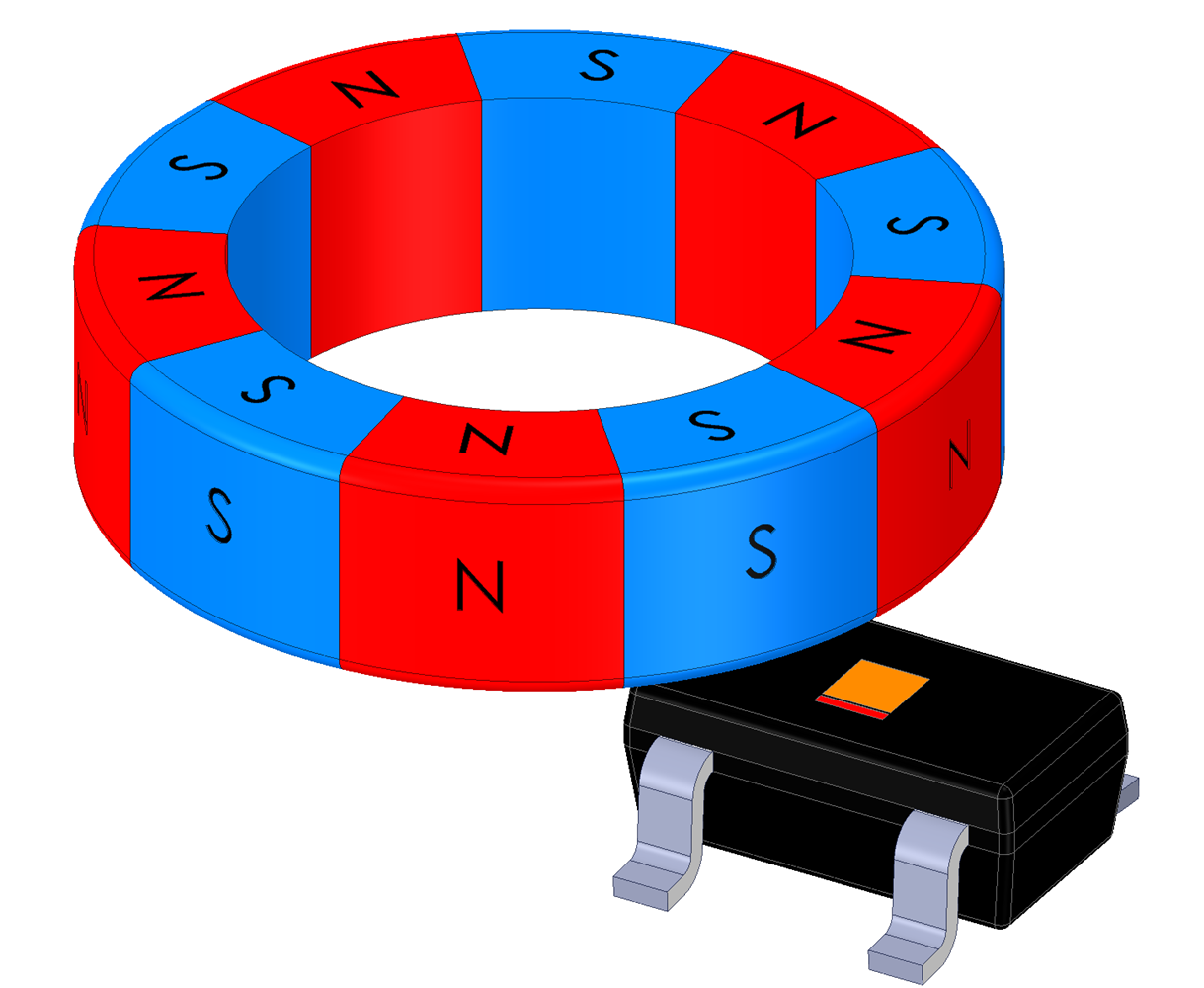

The side edge of the magnet still provides a magnetic field, but the field is much weaker than the field on the outer edge. Placing the sensor on the side edge minimizes the flexibility as of how far the device can be placed from the ring magnet. The 2 mT version enables high sensitivity, allowing the application to work as well as when the device is placed on the outer edge. Nevertheless this option can be helpful in application where the sensor has to fit within the magnet diameter.

| The options shown in Figure 8-11 and Figure 8-12 composed of X and Y axises enable the sensor to be placed facing the side edge of the magnet. The side of the sensor can also be placed next to the side edge of the magnet. The part can also be turned at 180 degrees along the Z axis. |

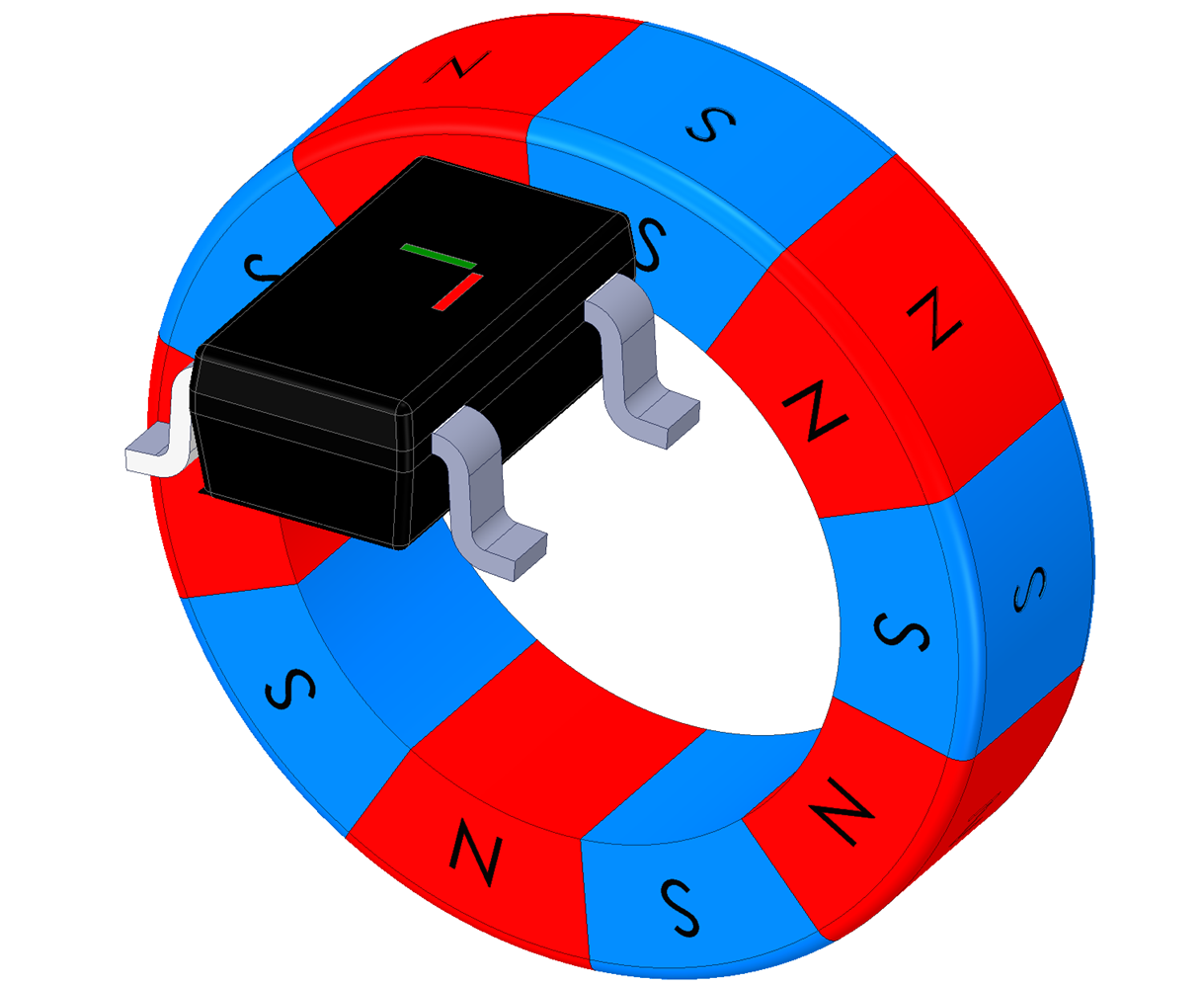

Figure 8-11 XY Side Edge 1

Figure 8-11 XY Side Edge 1 |

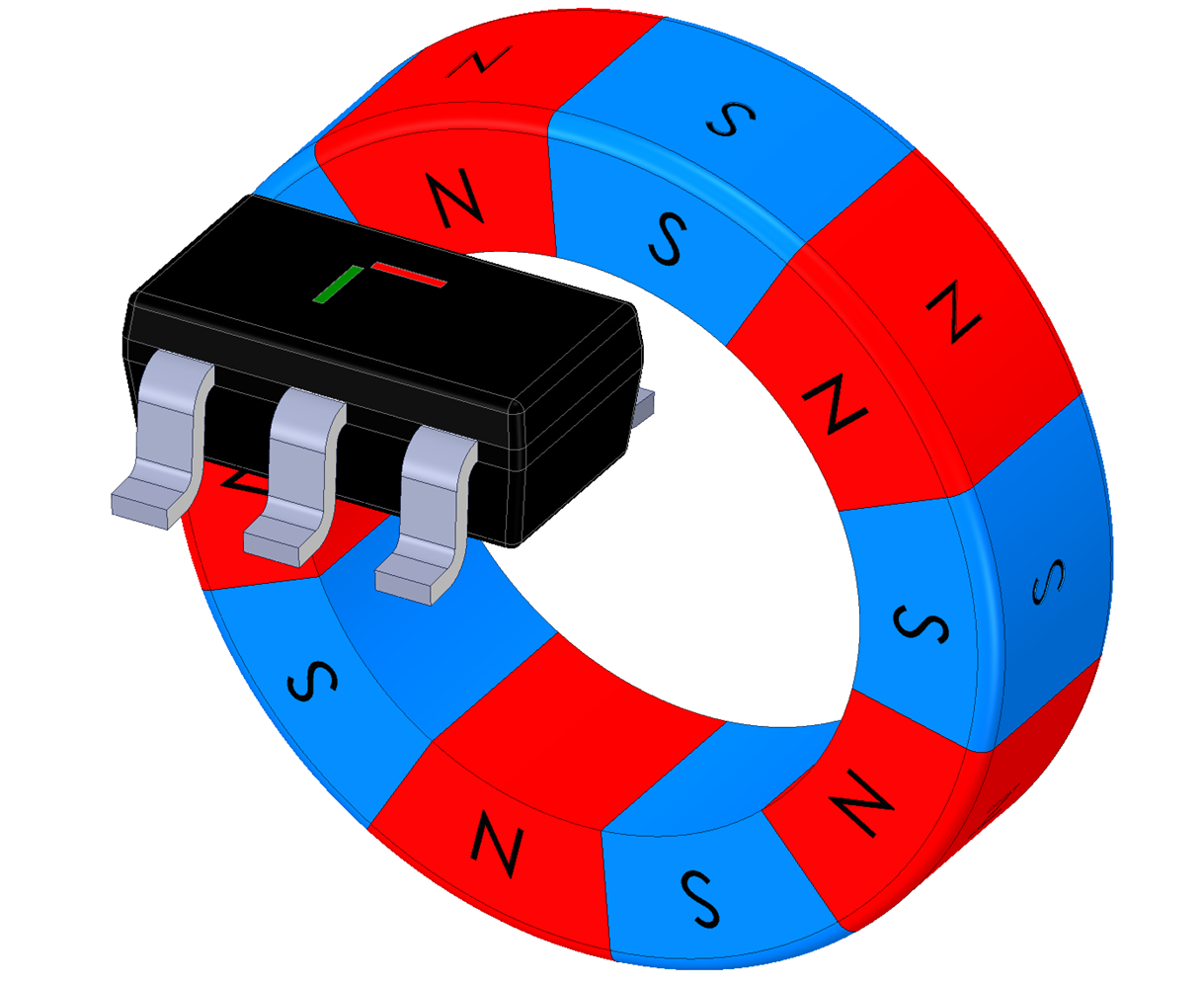

Figure 8-12 XY Side Edge 2

Figure 8-12 XY Side Edge 2 |

| The options shown in Figure 8-13 and Figure 8-14 composed of Z and X axis enable another way to place the sensor facing the side edge of the magnet. The top of the sensor can also be placed facing the side edge of the magnet. The part can also be turned at 180 degrees along the Z axis. |

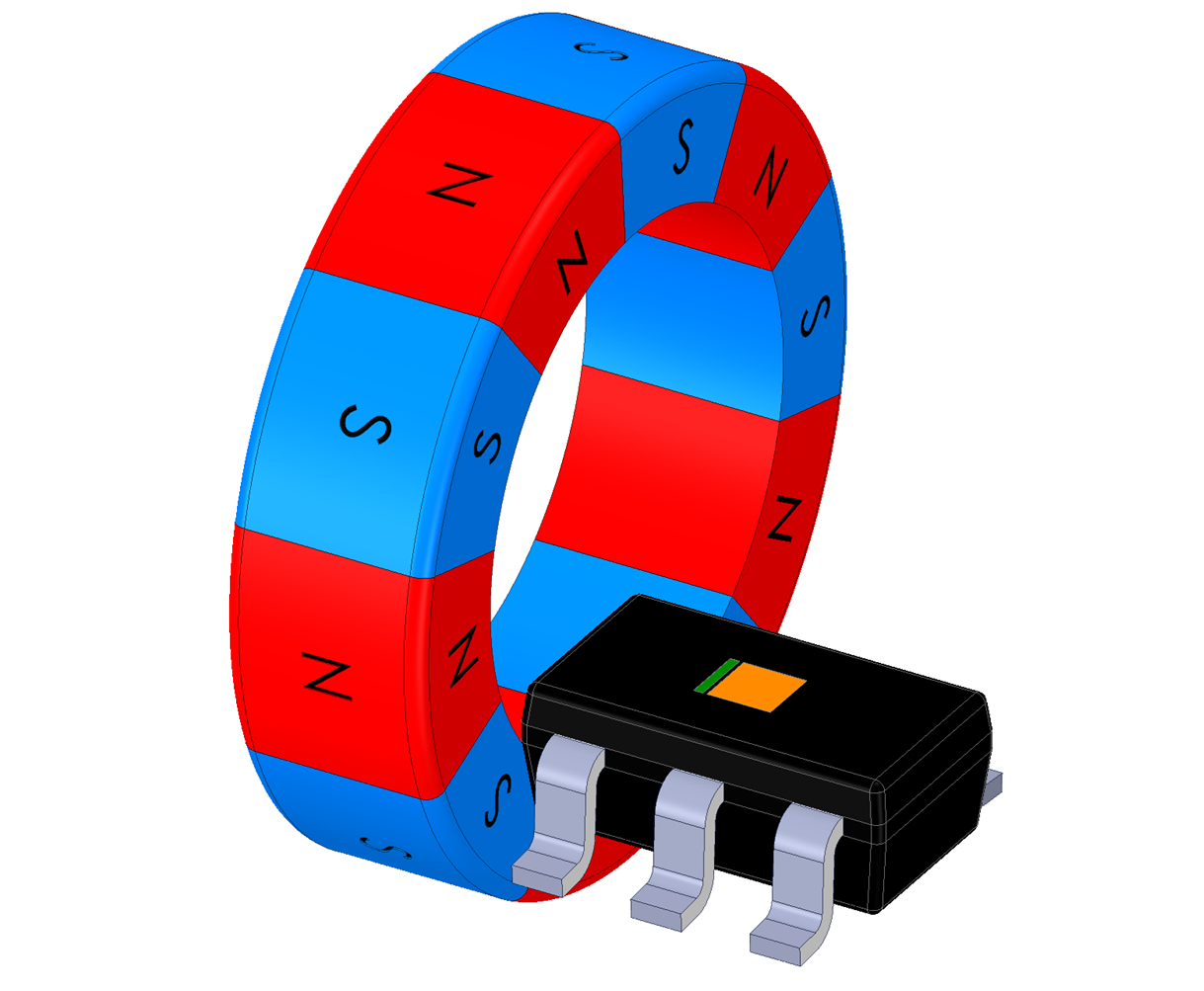

Figure 8-13 ZX Side Edge 1

Figure 8-13 ZX Side Edge 1 |

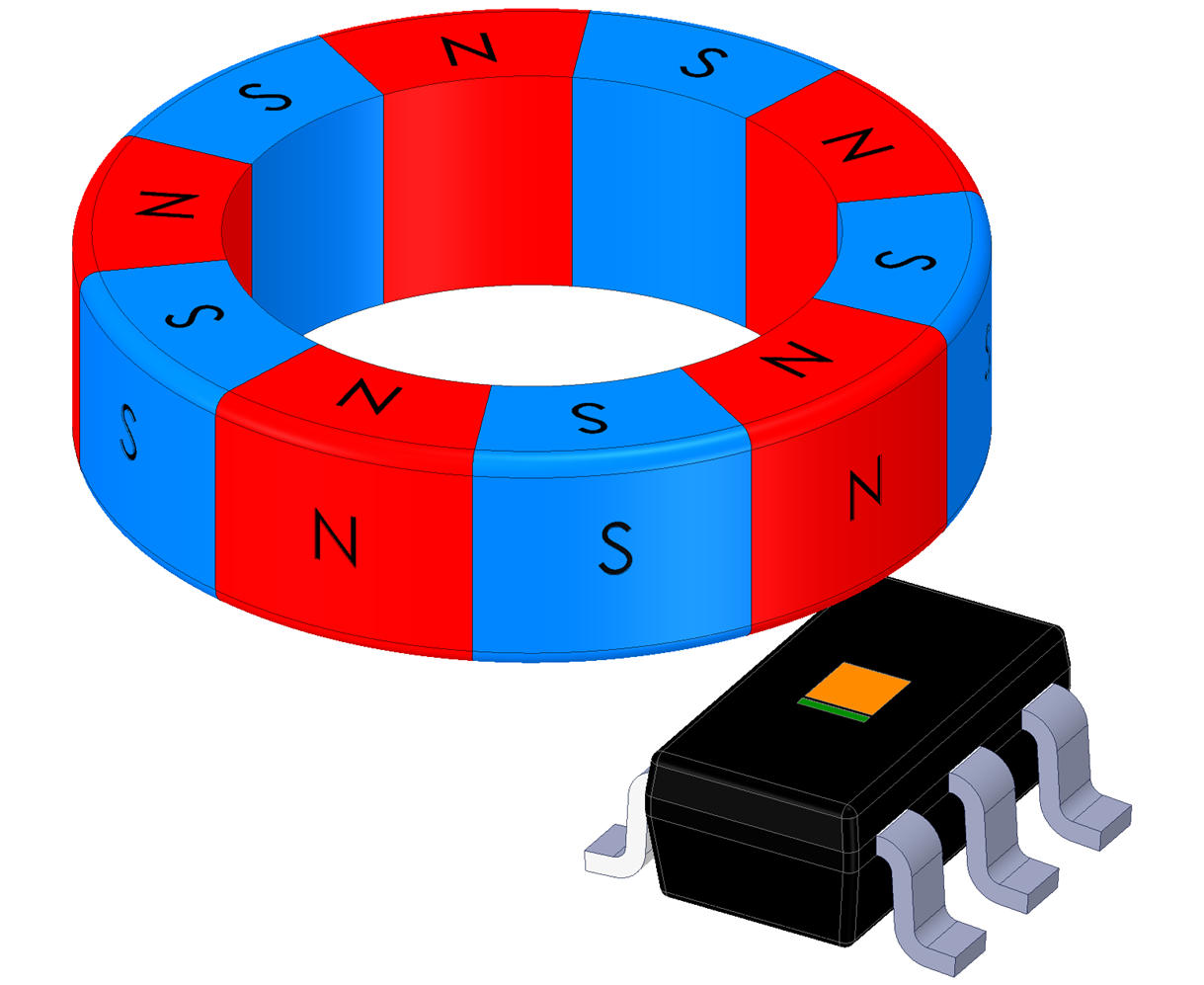

Figure 8-14 ZX Side Edge 2

Figure 8-14 ZX Side Edge 2 |

| The options shown in Figure 8-15 and Figure 8-16 composed of Z and Y axises enable the placement of the sensor on the side edge of a magnet with the pins facing the magnet, or with top of the sensor facing the side edge of the magnet. The part can also be turned at 180 degrees along the Z axis. |

Figure 8-15 ZY Side Edge 1

Figure 8-15 ZY Side Edge 1 |

Figure 8-16 ZY Side Edge 1

Figure 8-16 ZY Side Edge 1 |