SLVSCQ3B August 2015 – June 2016

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Detailed Description

-

9 Application and Implementation

- 9.1 Application Information

- 9.2 Typical Application

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DRC|10

Thermal pad, mechanical data (Package|Pins)

- DRC|10

Orderable Information

8 Detailed Description

8.1 Overview

The TPS25925x/6x is an e-fuse with integrated power switch that is used to manage current, voltage and start-up voltage ramp to a connected load. The device starts its operation by monitoring the VIN bus. When VIN exceeds the undervoltage-lockout threshold (VUVR), the device samples the EN/UVLO pin. A high level on this pin enables the internal MOSFET. As VIN rises, the internal MOSFET of the device starts conducting and allow current to flow from VIN to OUT. When EN/UVLO is held low (below VENF), internal MOSFET is turned off. User also has the ability to modify the output voltage ramp time by connecting a capacitor between dV/dT pin and GND.

After a successful start-up sequence, the device now actively monitors its load current and input voltage, ensuring that the adjustable overload current limit IOL is not exceeded and input voltage spikes are safely clamped to VOVC level at the output. This keeps the output device safe from harmful voltage and current transients. The device also has built-in thermal sensor. In the event device temperature (TJ) exceeds TSHDN, typically 150°C, the thermal shutdown circuitry shuts down the internal MOSFET thereby disconnecting the load from the supply. In TPS259250/60, the output remains disconnected (MOSFET open) until power to device is recycled or EN/UVLO is toggled (pulled low and then high). The TPS259251/61 device remains off and commences an auto-retry cycle of 145 ms after device temperature falls below TSHDN – 10°C. This auto-retry cycle continues until the fault is cleared.

8.2 Functional Block Diagram

8.3 Feature Description

8.3.1 GND

This is the most negative voltage in the circuit and is used as a reference for all voltage measurements unless otherwise specified.

8.3.2 VIN

Input voltage to the TPS25925x/6x. A ceramic bypass capacitor close to the device from VIN to GND is recommended to alleviate bus transients. The recommended operating voltage range is 4.5 V – 13.8 V for TPS25926x and 4.5 V – 5.5 V for TPS25925x. The device can continuously sustain a voltage of 20 V on VIN pin. However, above the recommended maximum bus voltage, the device is in over-voltage protection (OVP) mode, limiting the output voltage to VOVC. The power dissipation in OVP mode is PD_OVP = (VVIN – VOVC) × IOUT, which can potentially heat up the device and cause thermal shutdown.

8.3.3 dV/dT

Connect a capacitor from this pin to GND to control the slew rate of the output voltage at power-on. This pin can be left floating to obtain a predetermined slew rate (minimum TdVdT) on the output. Governing slew rate at start-up is shown in Equation 1.

Where:

IdVdT = 220 nA (TYPICAL)

CINT = 70 pF (TYPICAL)

GAINdVdT = 4.85

The total ramp time (TdVdT) for 0 to VIN can be calculated using Equation 2.

For details on how to select an appropriate charging time/rate, see the applications section Setting Output Voltage Ramp Time (TdVdT).

8.3.4 EN/UVLO

As an input pin, it controls both the ON and OFF state of the internal MOSFET. In its high state, the internal MOSFET is enabled and allows current to flow from VIN to OUT. A low on this pin turns off the internal MOSFET. High and Low levels are specified in the parametric table of the datasheet. The EN/UVLO pin is also used to clear a thermal shutdown latch in the TPS259250/60 by toggling this pin (H→L).

The internal de-glitch delay on EN/UVLO falling edge is intentionally kept low (1 µs typical) for quick detection of power failure. For applications where a higher de-glitch delay on EN/UVLO is desired, or when the supply is particularly noisy, it is recommended to use an external bypass capacitor from EN/UVLO to GND.

8.3.5 ILIM

The device continuously monitors the load current and keeps it limited to the value programmed by RILIM. After start-up event and during normal operation, current limit is set to IOL (over-load current limit). See Equation 3.

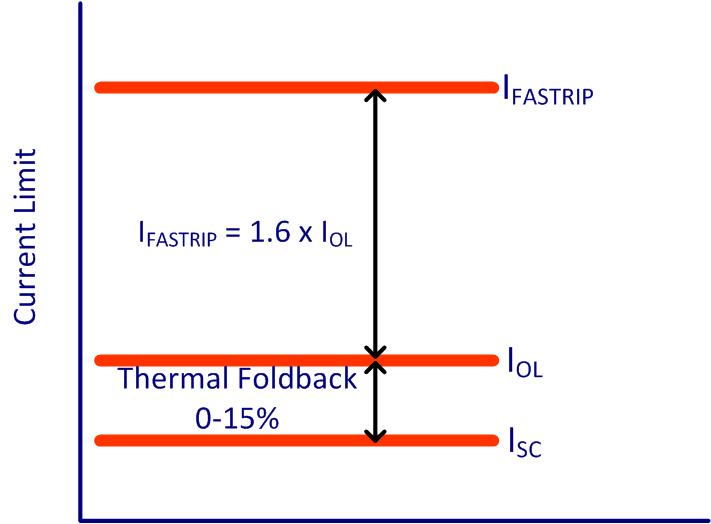

When power dissipation in the internal MOSFET [PD = (VVIN – VOUT) × IOUT] exceeds 10 W, there is a 2% to 12% thermal foldback in the current limit value so that IOL drops to ISC. In each of the two modes, MOSFET gate voltage is regulated to throttle short-circuit and overload current flowing to the load. Eventually, the device shuts down due to over temperature. See Figure 39.

Figure 39. Thermal Foldback in Current Limit

Figure 39. Thermal Foldback in Current Limit

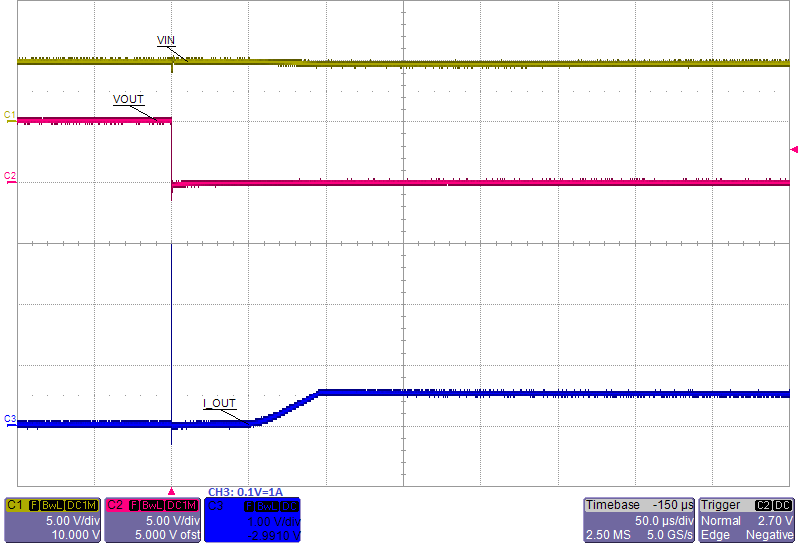

During a transient short circuit event, the current through the device increases very rapidly. The current-limit amplifier cannot respond to this event because of its limited bandwidth. Therefore, the TPS25925/6 incorporates a fast-trip comparator, which shuts down the pass device when IOUT > IFASTRIP, and terminates the rapid short-circuit peak current. The trip threshold is set to 60% higher than the programmed over-load current limit (IFASTRIP = 1.6 x IOL). After the transient short-circuit peak current has been terminated by the fast-trip comparator, the current limit amplifier smoothly regulates the output current to IOL. See Figure 40 and Figure 41.

Figure 40. Fast-Trip Current

Figure 40. Fast-Trip Current

Figure 41. Fast-Trip and Current Limit Amplifier Response for Short Circuit

Figure 41. Fast-Trip and Current Limit Amplifier Response for Short Circuit

8.4 Device Functional Modes

The TPS25925x/6x is a hot-swap controller with integrated power switch that is used to manage current, voltage and start-up voltage ramp to a connected load. The device starts its operation by monitoring the VIN bus. When VVIN exceeds the undervoltage-lockout threshold (VUVR), the device samples the EN/UVLO pin. A high level on this pin enables the internal MOSFET. As VIN rises, the internal MOSFET of the device starts conducting and allows current to flow from VIN to OUT. When EN/UVLO is held low (that is, below VENF), the internal MOSFET is turned off; thereby, blocking the flow of current from VIN to OUT. The user can modify the output voltage ramp time by connecting a capacitor between dV/dT pin and GND.

Having successfully completed its start-up sequence, the device now actively monitors the load current and input voltage, ensuring that the adjustable overload current limit IOL is not exceeded and input voltage spikes are safely clamped to VOVC level at the output. This keeps the output device safe from harmful voltage and current transients. The device also has built-in thermal sensor. If the device temperature (TJ) exceeds TSHDN, typically 150°C, the thermal shutdown circuitry shuts down the internal MOSFET; thereby, disconnecting the load from the supply. In the TPS259250/60, the output remains disconnected (MOSFET open) until power to device is recycled or EN/UVLO is toggled (pulled low and then high). The TPS259251/61 device remains off and commences an auto-retry cycle of 145 ms after device temperature falls below TSHDN – 10°C. This auto-retry cycle continues until the fault is cleared.