JAJU680A January 2019 – July 2022

- 概要

- Resources

- 特長

- アプリケーション

- 5

- 1System Description

- 2System Overview

- 3Hardware, Software, Testing Requirements, and Test Results

- 4Design and Documentation Support

- 5About the Authors

- 6Revision History

3.2.2.5 Flow Measurements

Flow measurements were performed on a 3D printable pipe with 200-kHz, 400-kHz, and 500-kHz transducers available from Jiakang, Hurricane, CeramTec, and Audiowell. The transducers are available from their respective manufacturers, and the 3D printable pipe design can be obtained from Texas Instruments.

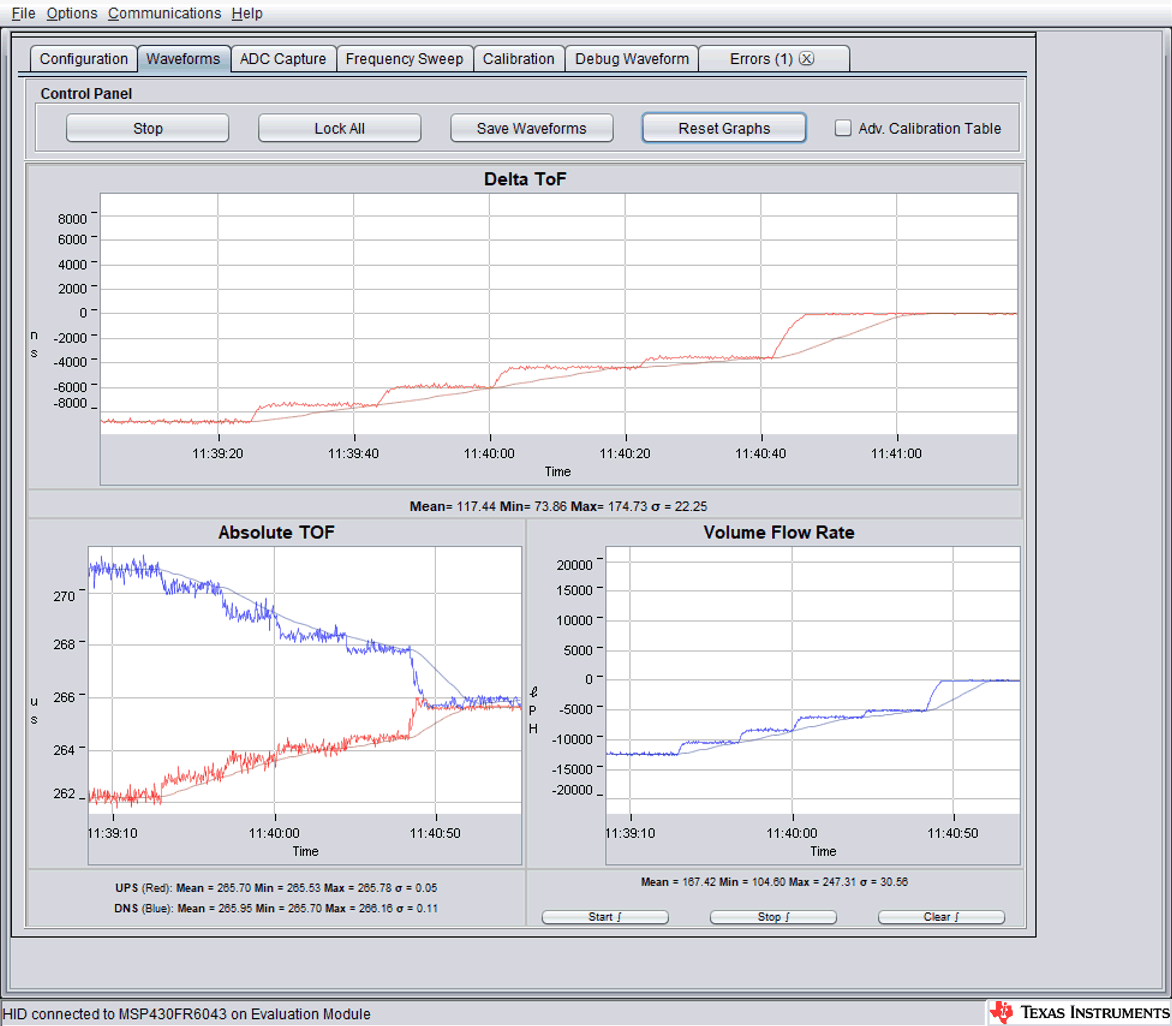

Variable flow rate testing was conducted with an ACE60 12V DC fan connected to the 3D printed pipe with 200-kHz transducers. Figure 4-18 shows the results of the differential ToF (dToF) and absolute ToF (aTOF) at different flow rates ranging from 12000 lph to 0 lph. The flow rate was initially decreased in steps of 2000 lph until the minimum operating voltage of the fan was reached. The flow rates appear negative because air was pulled(instead of pushed) through the pipe. The dToF of the 3D printed gas pipe was calibrated against a reference meter which was connected in series.

Figure 4-18 Flow Rate Testing

Figure 4-18 Flow Rate Testing